Odorless asphalt mixture and preparation method thereof

A technology for asphalt mixture and deodorization, which is applied in the field of road engineering materials, can solve the problems of large investment and high operating costs, and achieve the effects of strong capture ability, convenient construction and lower interface energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In addition, the present invention also provides a preparation method of clean taste asphalt mixture, comprising the following steps:

[0039] (1) Accurately weigh 40-60 parts of asphalt and heat it to 140-160°C, turn on the stirring device, add 0.1-0.5 parts of surfactant and 0.2-1 part of odor inhibitor, and stir for 30-40 minutes to prepare clean-taste asphalt;

[0040] (2) Heat the aggregate to 160-190°C and add the clean asphalt prepared in step (1) into the mixing pot and stir in the mixing pot for 90-120s;

[0041](3) Put the mineral powder into the mixing pot and stir for 90 seconds to obtain the clean-taste asphalt mixture.

Embodiment 4

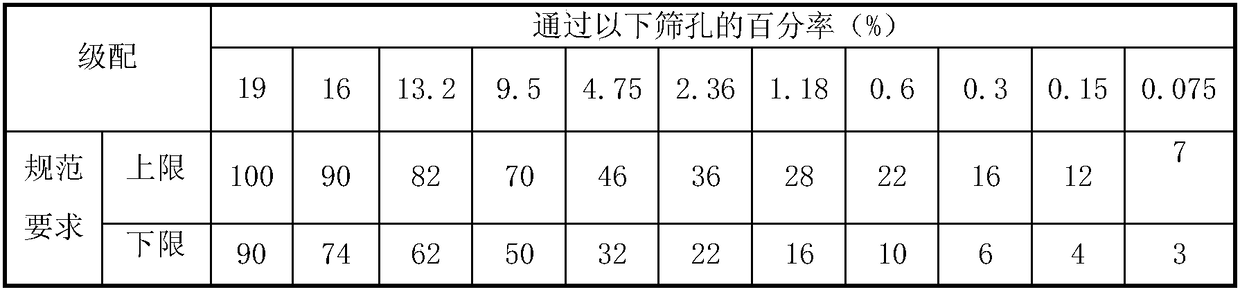

[0045] The aggregate gradation used in embodiment 4 and comparative example 2 is SMA-13 type, and the gradation parameters are as shown in table 2:

[0046] Table 2

[0047]

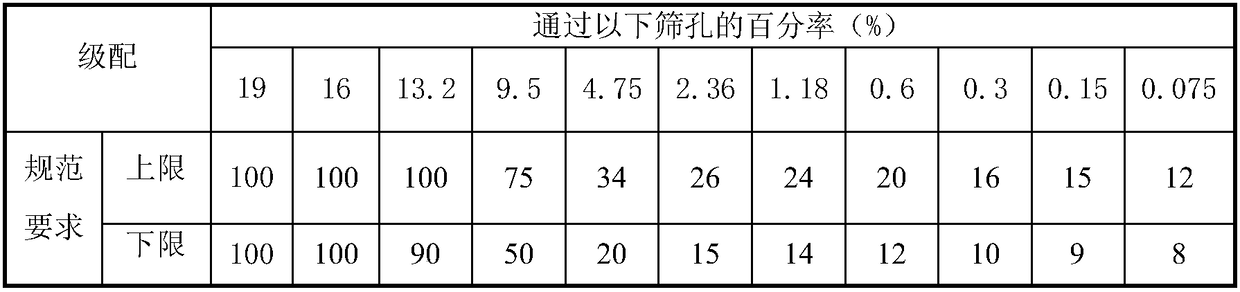

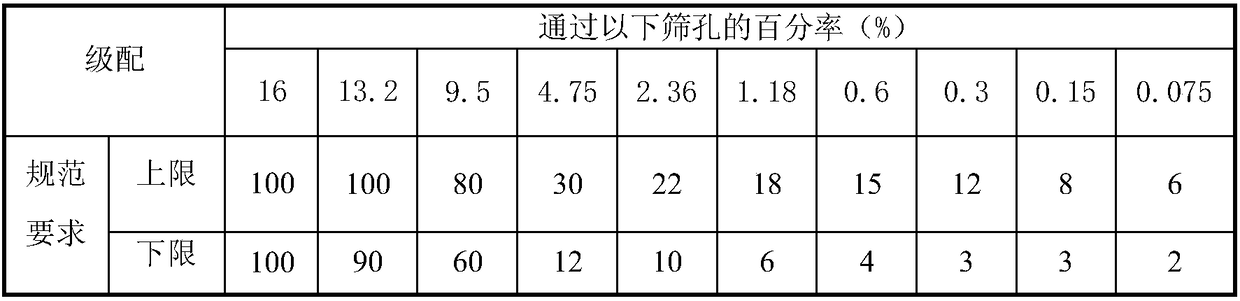

Embodiment 5

[0048] The aggregate gradation used in embodiment 5 and comparative example 3 is OGFC-13 type, and the gradation parameters are as shown in table 3:

[0049] table 3

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com