Ingot casting process for high-efficiency polycrystalline silicon

A polysilicon, high-efficiency technology, applied in the field of solar cells, can solve problems such as low conversion efficiency, and achieve the effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

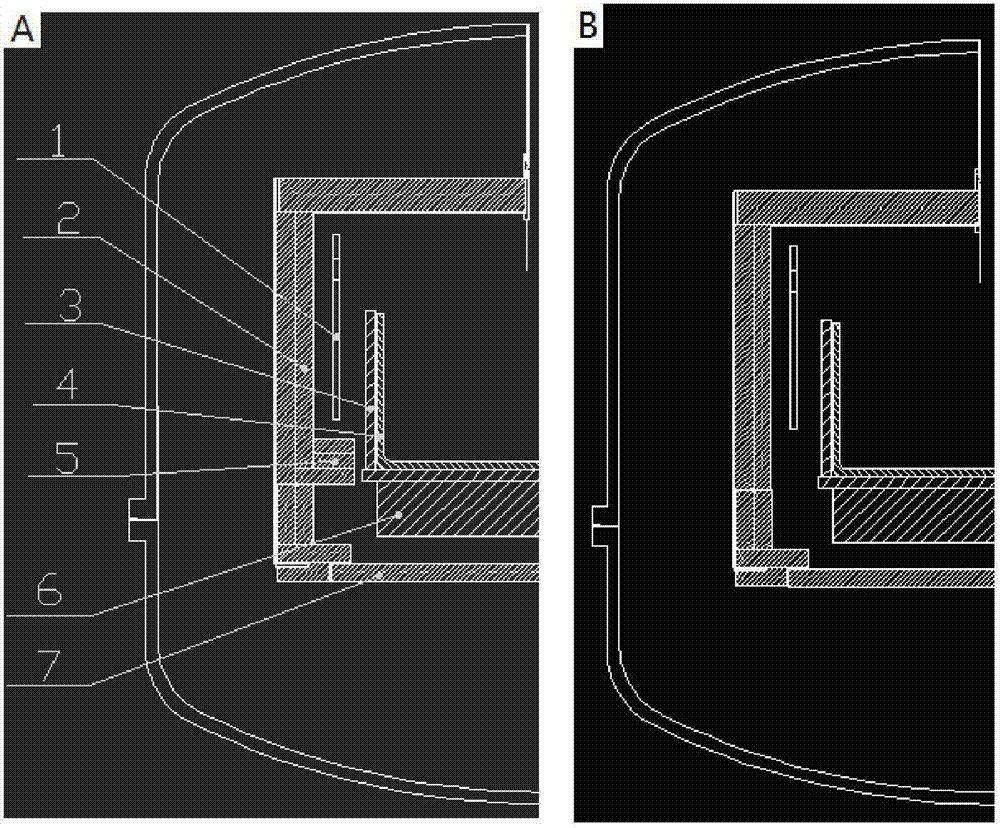

[0032] The high-efficiency polysilicon ingot casting method provided by this embodiment includes the following steps:

[0033] (1) Support and fix the carbon felt with a thickness of 150mm and a width of 80mm within 50~200mm below the heaters on both sides of the ordinary ingot casting furnace, and the carbon felt is close to the side wall insulation material;

[0034] (2) Put the silicon raw material and the boron-silicon alloy into the crucible, about 480kg in total, and the target resistivity is 1.5Ω·cm;

[0035] (3) Put the crucible filled with silicon material into the ingot furnace, evacuate and heat, and control the heater to gradually increase the temperature in the furnace to 1540°C. When the silicon material and the electroactive dopant are completely melted, the crucible The bottom temperature is 1400°C;

[0036] (4) After melting, jump into crystal growth. In the initial stage of crystal growth, quickly lower the temperature from 1540°C to 1425°C, and at the same ...

Embodiment 2

[0041] The high-efficiency polysilicon ingot casting method provided by this embodiment includes the following steps:

[0042] (1) Support and fix the carbon felt with a thickness of 200mm and a width of 90mm within the range of 50~250mm below the common ingot furnace heater, and the carbon felt is close to the side wall insulation material;

[0043] (2) Put the silicon raw material and the boron-silicon alloy into the crucible, about 480kg in total, and the target resistivity is 1.7Ω·cm;

[0044] (3) Put the crucible filled with silicon material into the ingot furnace, evacuate and heat, and control the heater to gradually increase the temperature in the furnace to 1540°C. When the silicon material and the electroactive dopant are completely melted, the crucible The bottom temperature is 1405°C;

[0045] (4) After melting, jump into crystal growth. In the initial stage of crystal growth, quickly lower the temperature from 1540°C to 1425°C, and at the same time quickly open t...

Embodiment 3

[0050] The high-efficiency polysilicon ingot casting method provided by this embodiment includes the following steps:

[0051] (1) Support and fix a carbon felt with a thickness of 250mm and a width of 100mm within the range of 50~300mm below the common ingot furnace heater, and the carbon felt is close to the side wall insulation material;

[0052] (2) Put the silicon raw material and the boron-silicon alloy into the crucible, about 480kg in total, and the target resistivity is 1.9Ω·cm;

[0053] (3) Put the crucible filled with silicon material into the ingot furnace, evacuate and heat, and control the heater to gradually increase the temperature in the furnace to 1540°C. When the silicon material and the electroactive dopant are completely melted, the crucible The bottom temperature is 1405°C;

[0054] (4) After melting, jump into crystal growth. In the early stage of crystal growth, quickly lower the temperature from 1540°C to 1430°C, and at the same time quickly open the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com