High ductility nickel-free ferrite stainless steel and manufacturing method thereof

A manufacturing method, stainless steel technology, applied in the field of alloy steel, can solve the problems of short service life, low solubility, difficulty in preventing the precipitation of carbon and nitrogen compounds, etc., and achieve the effect of improving service life and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

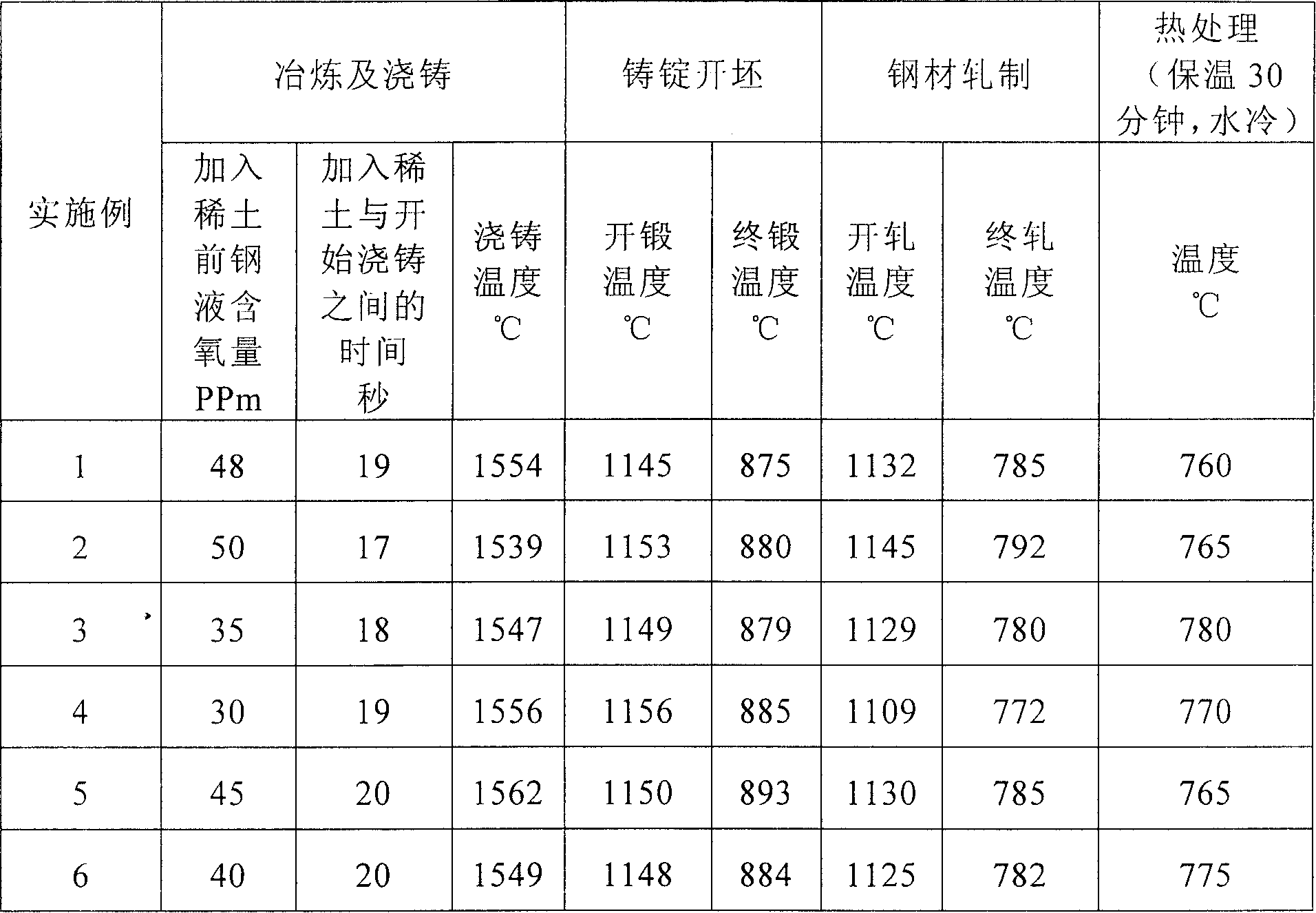

[0033] Embodiment see table 1, table 2. According to the chemical composition of the nickel-free rare earth-containing ferritic stainless steel of the present invention, it is smelted on a vacuum induction furnace, and its chemical composition (wt%) is shown in Table 1 and Table 2 respectively. After smelting, it is cast into an ingot, and then the ingot billeting, steel rolling and heat treatment are carried out according to the process steps of its preparation method. The parameters related to smelting, ingot casting and steel rolling are shown in Table 3. Subsequently, the product steel was sampled, and the tensile test, room temperature and low temperature impact toughness tests were carried out respectively, and the results were listed in Table 4 and Table 5 respectively.

[0034] It can be seen from Table 4 that the strength and elongation are equivalent to those of SUS430. It can be seen from Table 5 that the impact toughness (room temperature, low temperature) is sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com