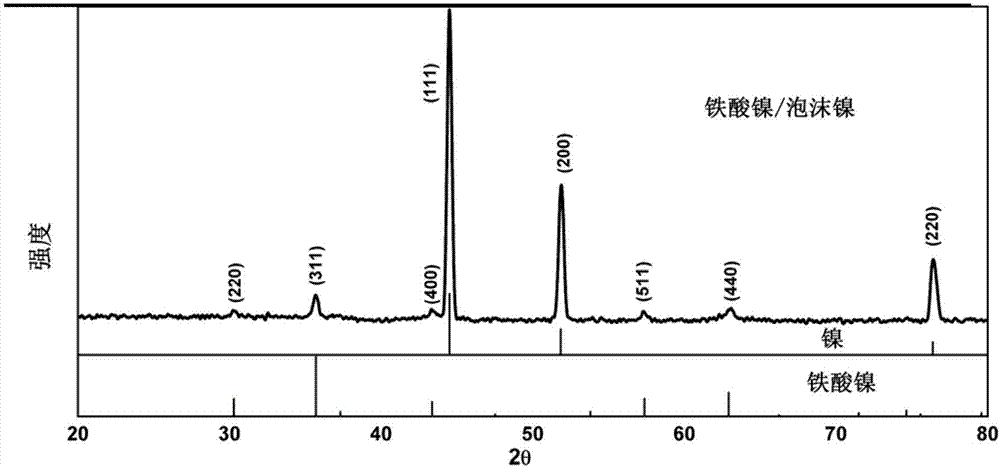

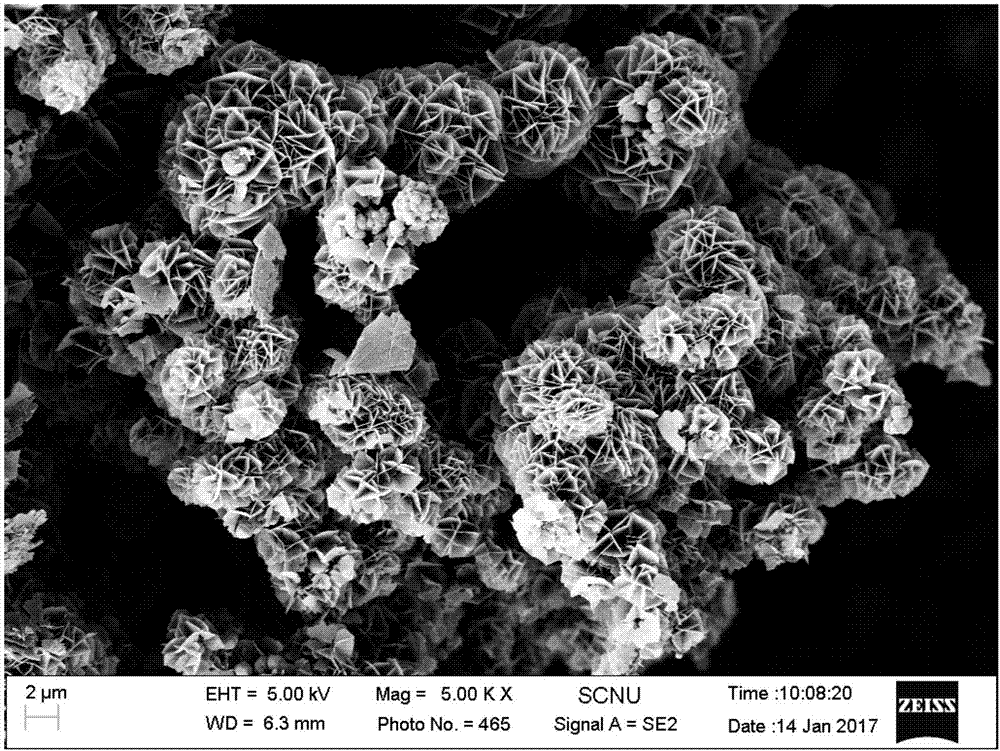

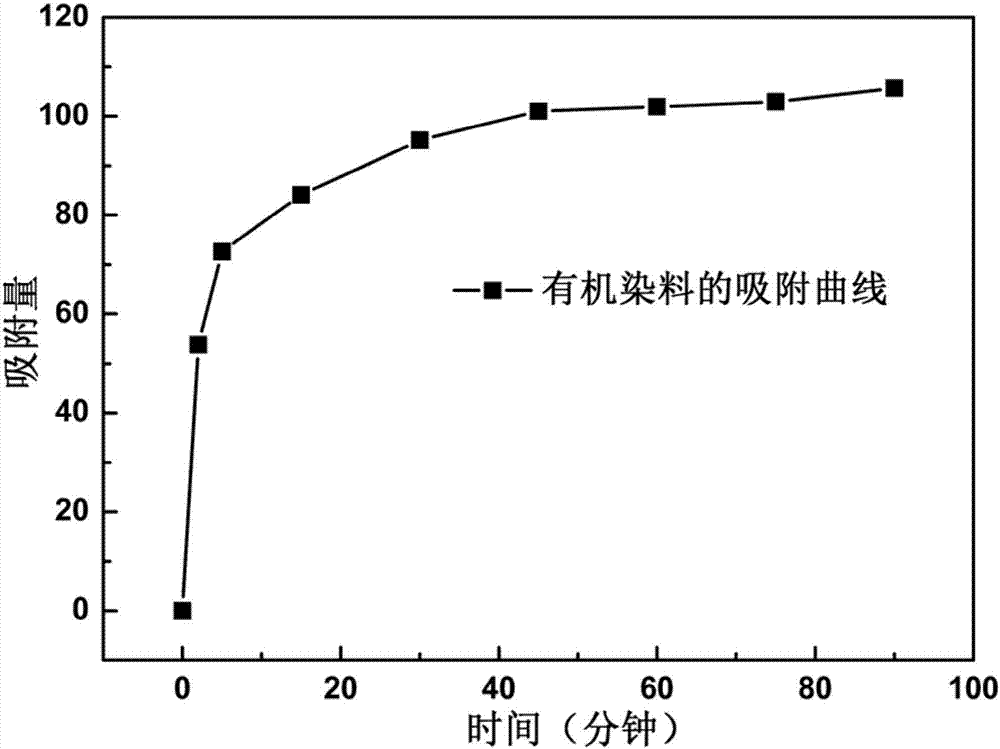

Water treatment nickel-based self-growing three-dimensional material and preparation method thereof

A self-growing and water treatment technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of complex material synthesis process, unsatisfactory adsorption effect and high production cost, Achieve the effect of large specific surface area, simplify sewage treatment process and reduce treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) First cut the foamed nickel (110ppi foamed nickel) into a rectangle (0.690 g) of 4*6*0.05 cm, the width is similar to the inner diameter of the reactor, and the length is flush with the page, so that the foamed nickel remains upright during the reaction , which is conducive to a more uniform reaction. Then put the cut nickel foam into a 200mL beaker, pour 100mL of acetone into it and sonicate for 30min with a power of 240w. Then pour off the acetone, rinse with deionized water, and then pour 100mL of absolute ethanol into the same ultrasonic wave for 30min (power 240w). Finally, the absolute ethanol was poured out, rinsed with deionized water, and then ultrasonicated with deionized water for 30 minutes (power 240w). After the ultrasonication is completed, the treated foamed nickel is vertically placed in a 150mL autoclave.

[0060] (2) Weigh 1.163g of nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O), 2.224g of ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) mix...

Embodiment 2

[0066] (1) First cut the foamed nickel (110ppi foamed nickel) into a rectangle (0.690 g) of 4*6*0.05 cm, the width is similar to the inner diameter of the reactor, and the length is flush with the page, so that the foamed nickel remains upright during the reaction , which is conducive to a more uniform reaction. Then put the cut nickel foam into a 200mL beaker, pour 100mL of acetone into it and sonicate for 40min with a power of 200w. Then pour out the acetone, rinse with deionized water, and then pour 100mL of absolute ethanol into the same sonication for 40min (power 200w). Finally, the absolute ethanol was poured out, rinsed with deionized water, and then ultrasonicated with deionized water for 40 minutes (power 200w). After the ultrasonication is completed, the treated foamed nickel is vertically placed in a 150mL autoclave.

[0067] (2) Weigh respectively 2.328g of nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O), 4.896g of ferrous sulfate heptahydrate (FeSO 4 ·7H ...

Embodiment 3

[0073] (1) First cut the foamed nickel (110ppi foamed nickel) into a rectangle (0.690 g) of 4*6*0.05 cm, the width is similar to the inner diameter of the reactor, and the length is flush with the page, so that the foamed nickel remains upright during the reaction , which is conducive to a more uniform reaction. Then put the cut nickel foam into a 200mL beaker, pour 100mL of acetone into it and sonicate for 50min with a power of 180w. Then pour off the acetone, rinse with deionized water, and then pour 100mL of absolute ethanol into the same sonication for 50min (ultrasonic power is 180w). Finally, deionized ethanol was poured out, rinsed with deionized water, and then ultrasonicated with deionized water for 50 min (ultrasonic power: 180w). After the ultrasonication is completed, the treated foamed nickel is vertically placed in a 150mL autoclave.

[0074] (2) Weigh 1.163g of nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O), 2.224g of ferrous sulfate heptahydrate (FeSO 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com