Preparation of cobalt nickel ferrite/ polyvinyl pyrrolidone composite magnetic nano fibers

A polyvinylpyrrolidone, cobalt-nickel ferrite technology, which is applied in the directions of fiber treatment, fibrous filler, fiber chemical characteristics, etc., can solve the problems of poor dispersion and uneven fiber diameter distribution, and achieves simple process and uniform diameter distribution. , The effect of low production equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 1.35g Co 1-x Ni x Fe 2 o 4 (x=0.2) particles, dispersed in 18ml of toluene solution, mechanically ultrasonically stirred at 600 rpm at room temperature for 1h, then added dropwise 3.6ml of silane coupling agent KH-570 (brand A-174) under nitrogen atmosphere, Mechanically ultrasonically stir at 300 rpm / min for 6 h at room temperature, collect the product with a magnet, wash with dichloromethane and ethanol, and bake at 50°C for 18 h to obtain the modified Co 0.8 Ni 0.2 Fe 2 o 4 nanoparticles;

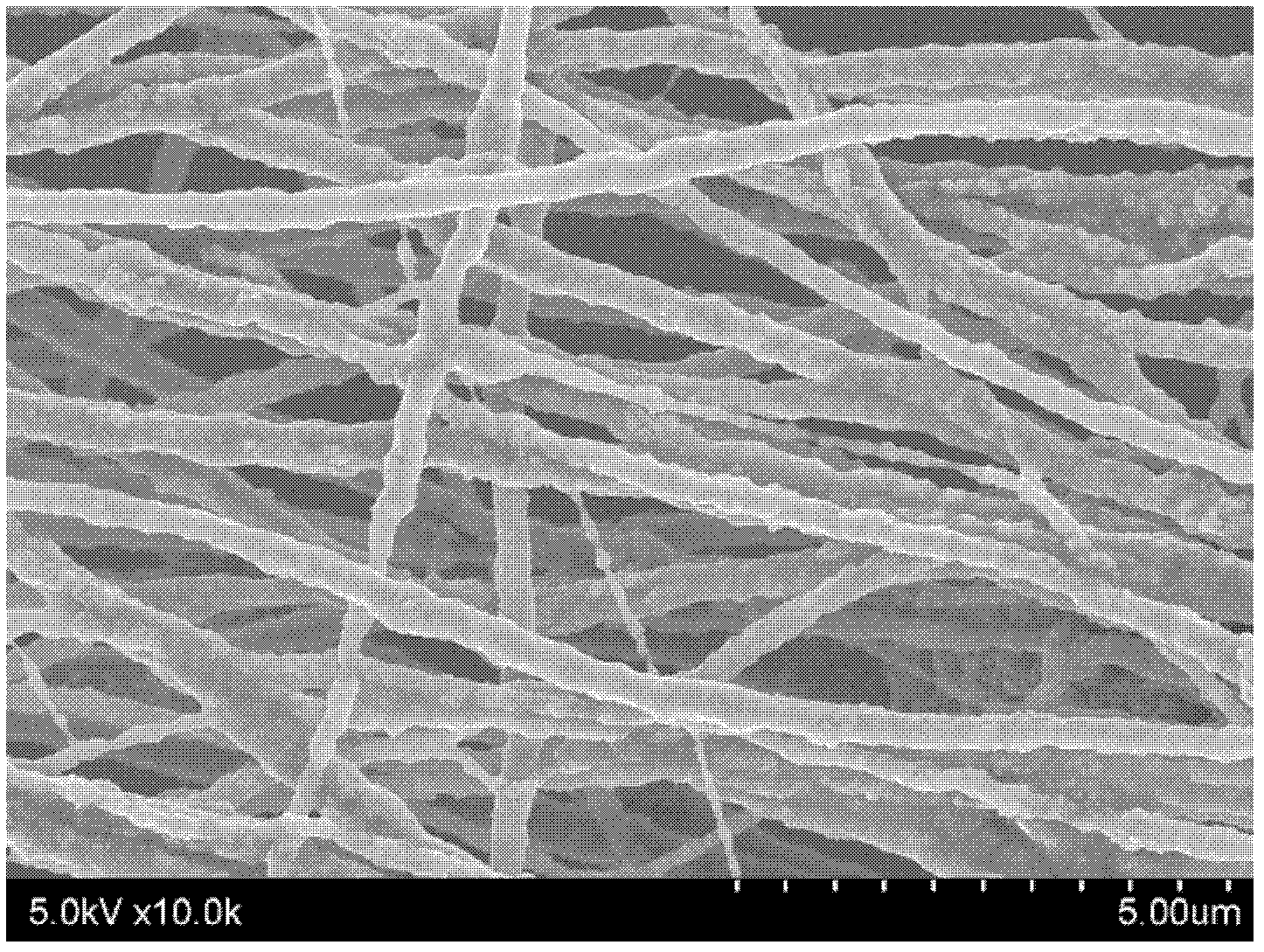

[0032] (2) Weigh 0.45g of PVP (30000) and dissolve it in 5.2ml of ethanol, mechanically ultrasonically stir at 600 rpm at room temperature for 12h, and disperse 1.35g of modified cobalt-nickel ferrite particles in the PVP solution to make the ferrite The mass ratio of particles to PVP was 3:1, mechanical ultrasonic stirring at 600 rpm at room temperature for 12 hours, the mixed solution was injected into a plastic syringe, fixed on a microfluidic pump, at a propul...

Embodiment 2

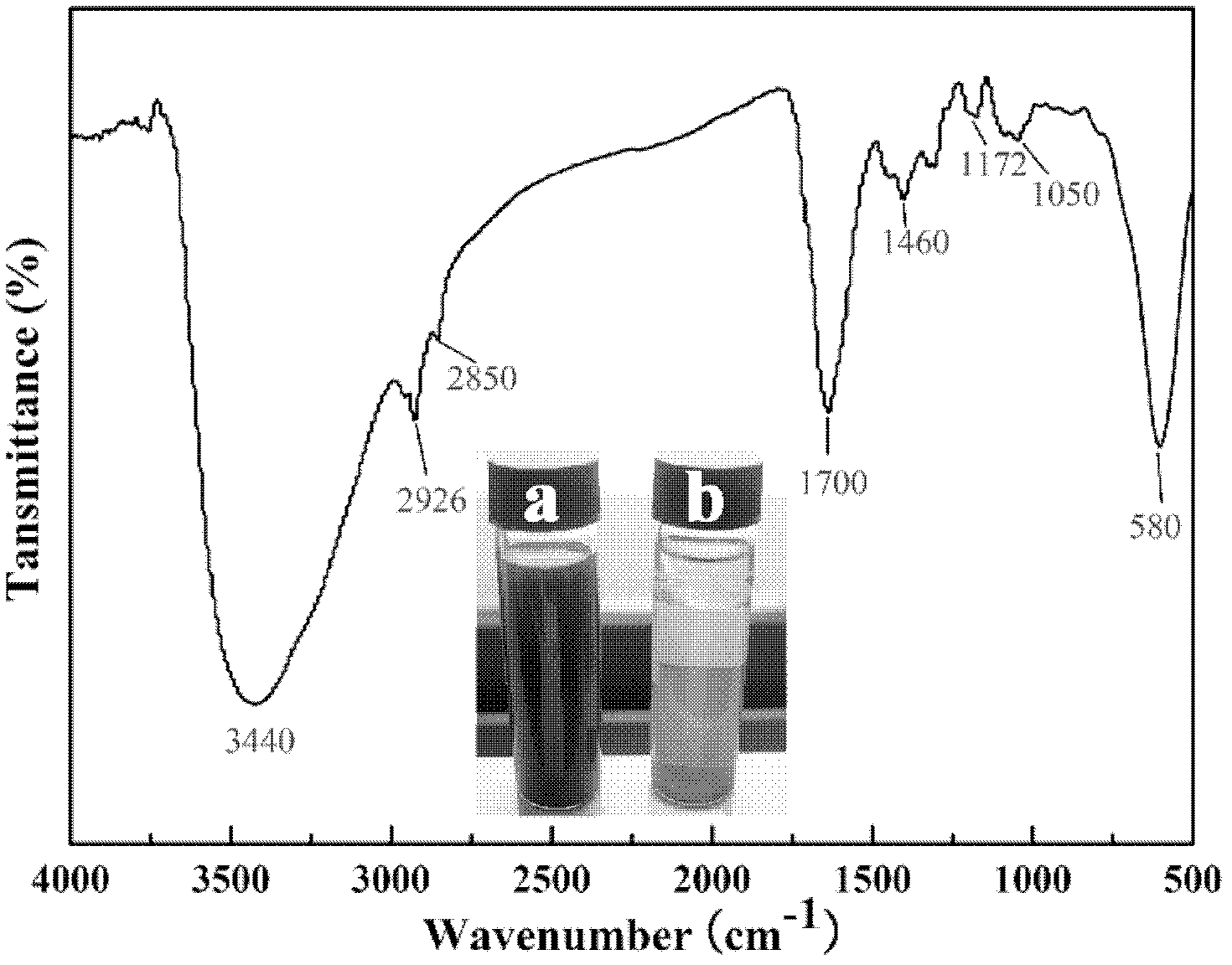

[0036] (1) Weigh 1.6g Co 1-x Ni x Fe 2 o 4 (x=0.6) particles, dispersed in 25ml of toluene solution, mechanically ultrasonically stirred at 300 rpm at room temperature for 2h, then added dropwise 1.75ml of silane coupling agent KH-570 (brand name SH-6030) under nitrogen atmosphere, Mechanically ultrasonically stir at 600 rpm at room temperature for 4 hours, collect the product with a magnet, wash with dichloromethane and ethanol, and bake at 40°C for 24 hours to obtain the modified Co 0.4 Ni 0.6 Fe 2 o 4 Nanoparticles; The Fourier transform infrared spectrum of the modified ferrite particles shows that the silane coupling agent KH-570 has been grafted on the surface of the magnetic particles.

[0037] (2) Weigh 0.4g of PVP (100000) and dissolve it in 5.8ml of ethanol, mechanically ultrasonically stir at 400 rpm at room temperature for 18h, and disperse 1.6g of modified cobalt-nickel ferrite particles in the PVP solution to make the ferrite The mass ratio of particles to...

Embodiment 3

[0040] (1) Weigh 1.0g Co 1-x Ni x Fe 2 o 4 (x=0.4) particles, dispersed in 20ml of toluene solution, mechanically ultrasonically stirred at 400 rpm at room temperature for 1.5h, then added dropwise 2.0ml of silane coupling agent KH-570 (brand name KBM-503) under nitrogen atmosphere , mechanically ultrasonically stirred at 400 rpm / min at room temperature for 5 hours, collected the product with a magnet, washed with dichloromethane and ethanol, and baked at 60°C for 12 hours to obtain the modified Co 0.4 Ni 0.6 Fe 2 o 4 Nanoparticles; The Fourier transform infrared spectrum of the modified ferrite particles shows that the silane coupling agent KH-570 has been grafted on the surface of the magnetic particles.

[0041] (2) Weigh 0.5g of PVP (1300000) and dissolve it in 6.4ml of ethanol, mechanically ultrasonically stir at 600 rpm at room temperature for 12h, and disperse 1.0g of modified cobalt-nickel ferrite particles in the PVP solution to make the ferrite The mass ratio ...

PUM

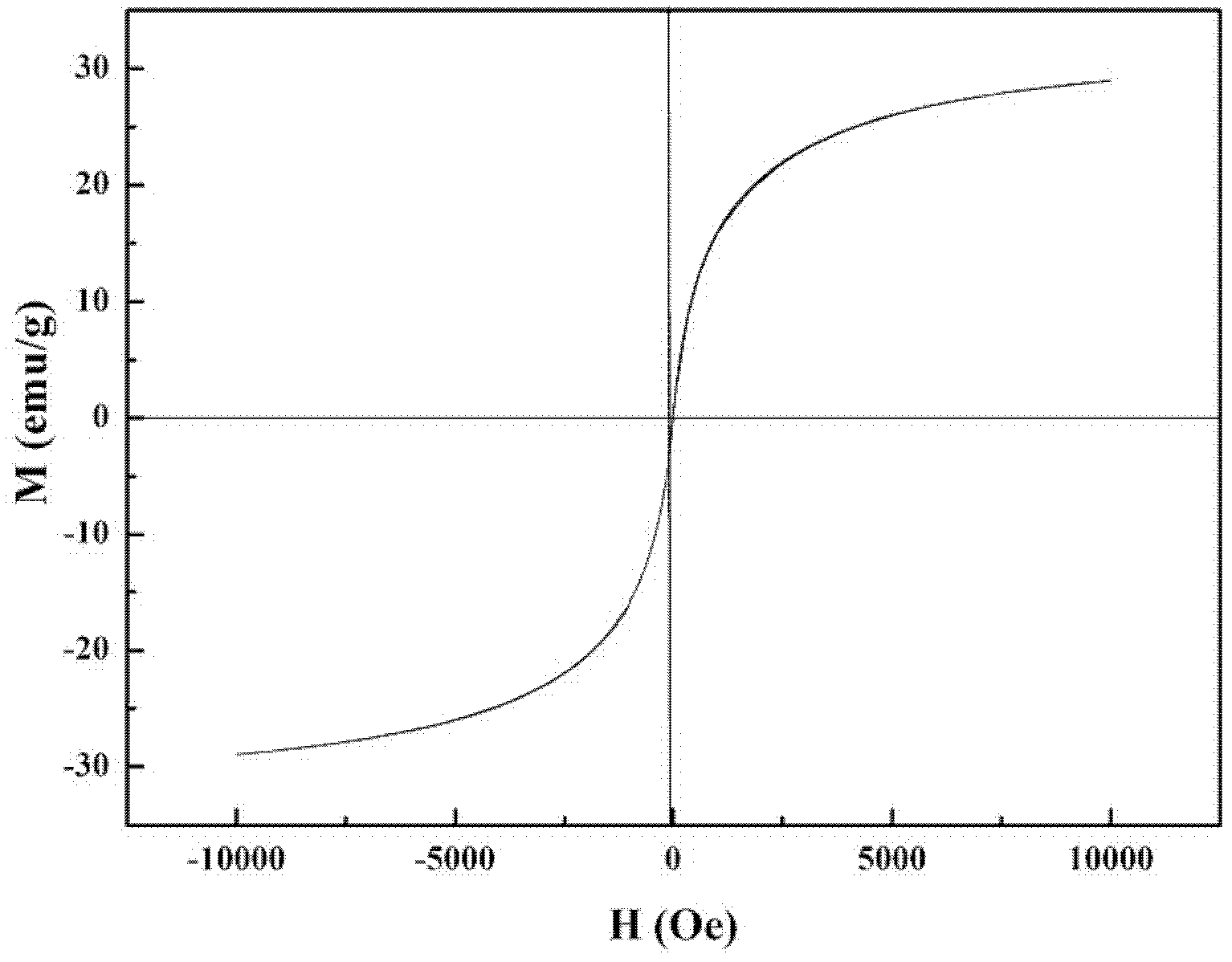

| Property | Measurement | Unit |

|---|---|---|

| Magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com