Preparation method of Cu2O/NiFe2O4 magnetic composite

A composite, magnetic technology, applied in the fields of iron compounds, inorganic material magnetism, chemical instruments and methods, etc., can solve problems such as difficulty in recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

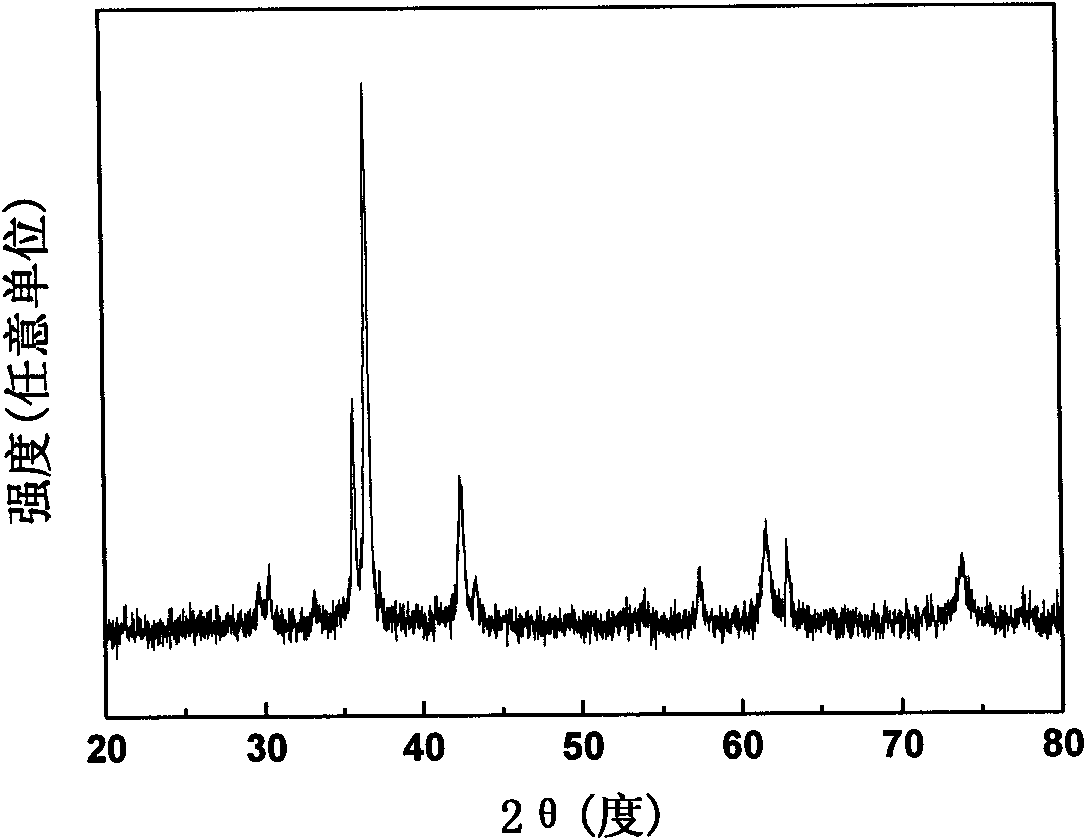

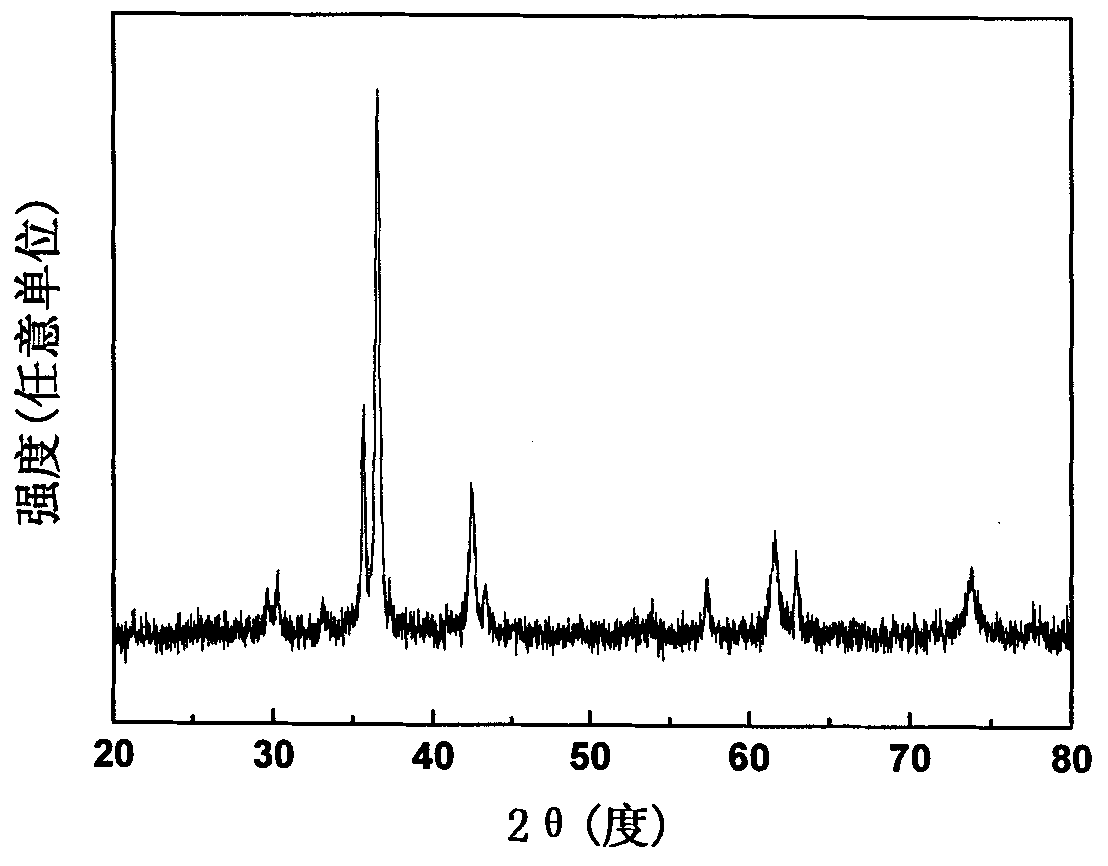

Image

Examples

Embodiment

[0017] Embodiment: the preparation process and steps in this embodiment are as follows:

[0018] (1), 2.43g FeCl 3 ·6H 2 O and 1.31gNi(NO 3 ) 2 ·6H 2 O was dissolved in 60ml of distilled water, 1.0g of polyvinylpyrrolidone was added, and the pH was adjusted to 10 (measured by pH test paper) with NaOH solution, stirred evenly with a magnetic stirrer, and loaded into a high-pressure reaction with a polytetrafluoroethylene lining in a volume of 100ml. Kettle, placed in a muffle furnace at 200 ° C constant temperature 8h. After the reaction is completed and the sample is cooled, the remaining waste liquid of the reaction is removed, and the reaction product obtained is transferred to a beaker. The product was repeatedly washed with deionized water to pH 7, and then washed with absolute ethanol. After suction filtration, the sample was dried at 60°C for 3 hours and taken out, and the product was brown nickel ferrite.

[0019] (2), 2.5g CuSO 4 ·5H 2 O and 1g of glucose are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com