Method for preparing cobalt-nickel ferrite/graphene magnetic nanocomposite powder by alcohol thermal method

A cobalt-nickel ferrite and magnetic nanotechnology, which is applied in the field of preparation of cobalt-nickel ferrite/graphene magnetic nanocomposite powder by alcohol thermal method, which achieves the effect of good dispersion, good application prospect and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

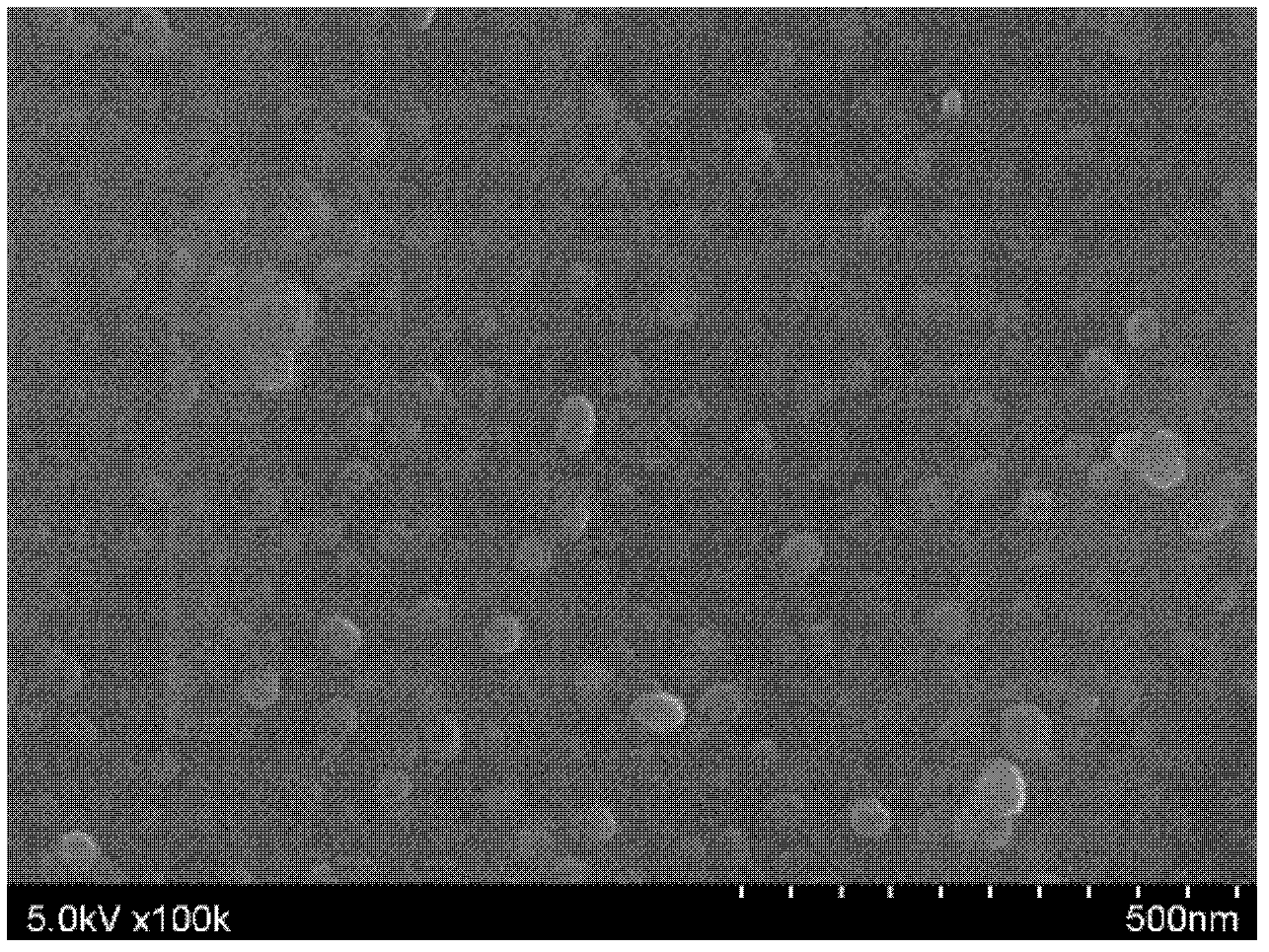

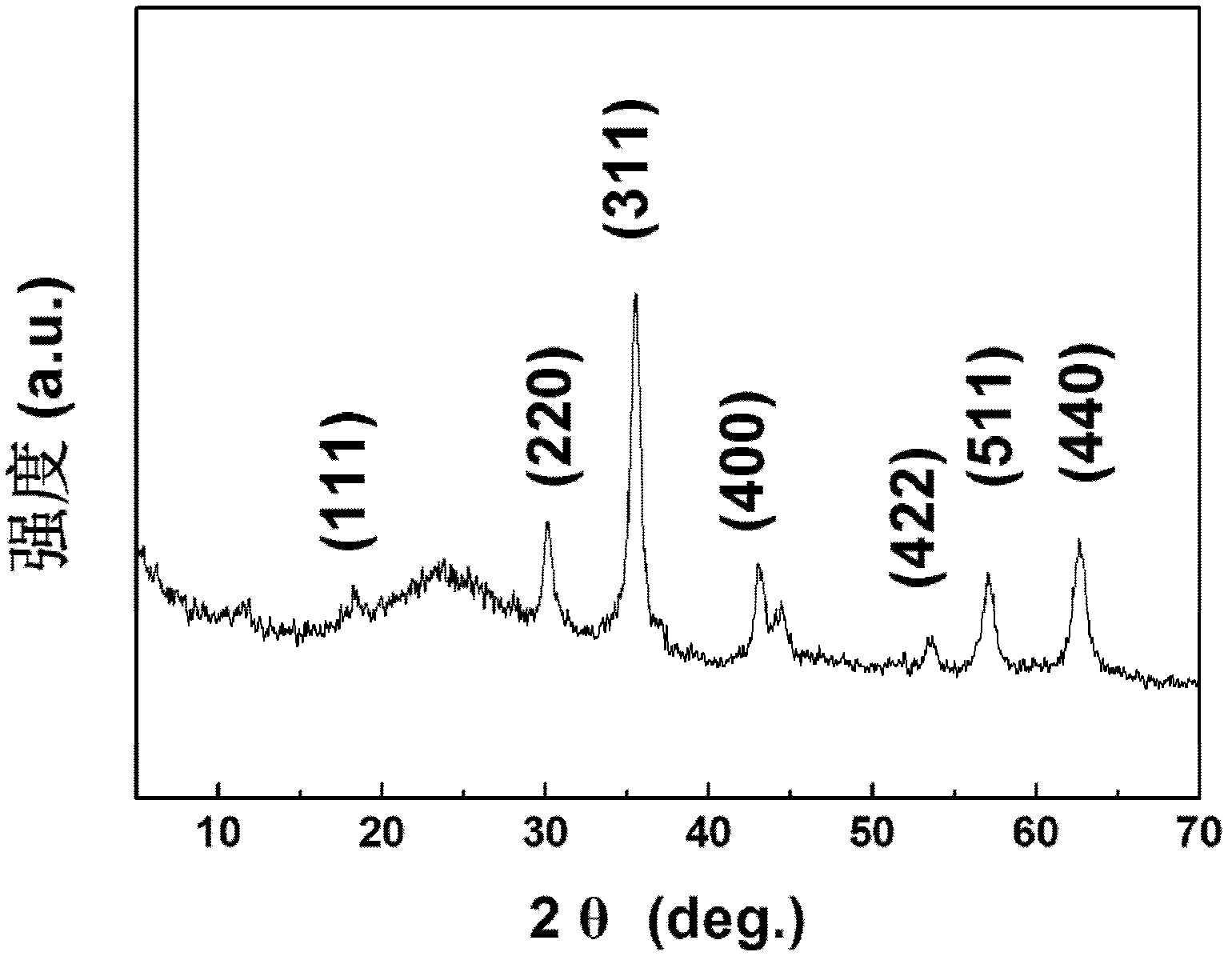

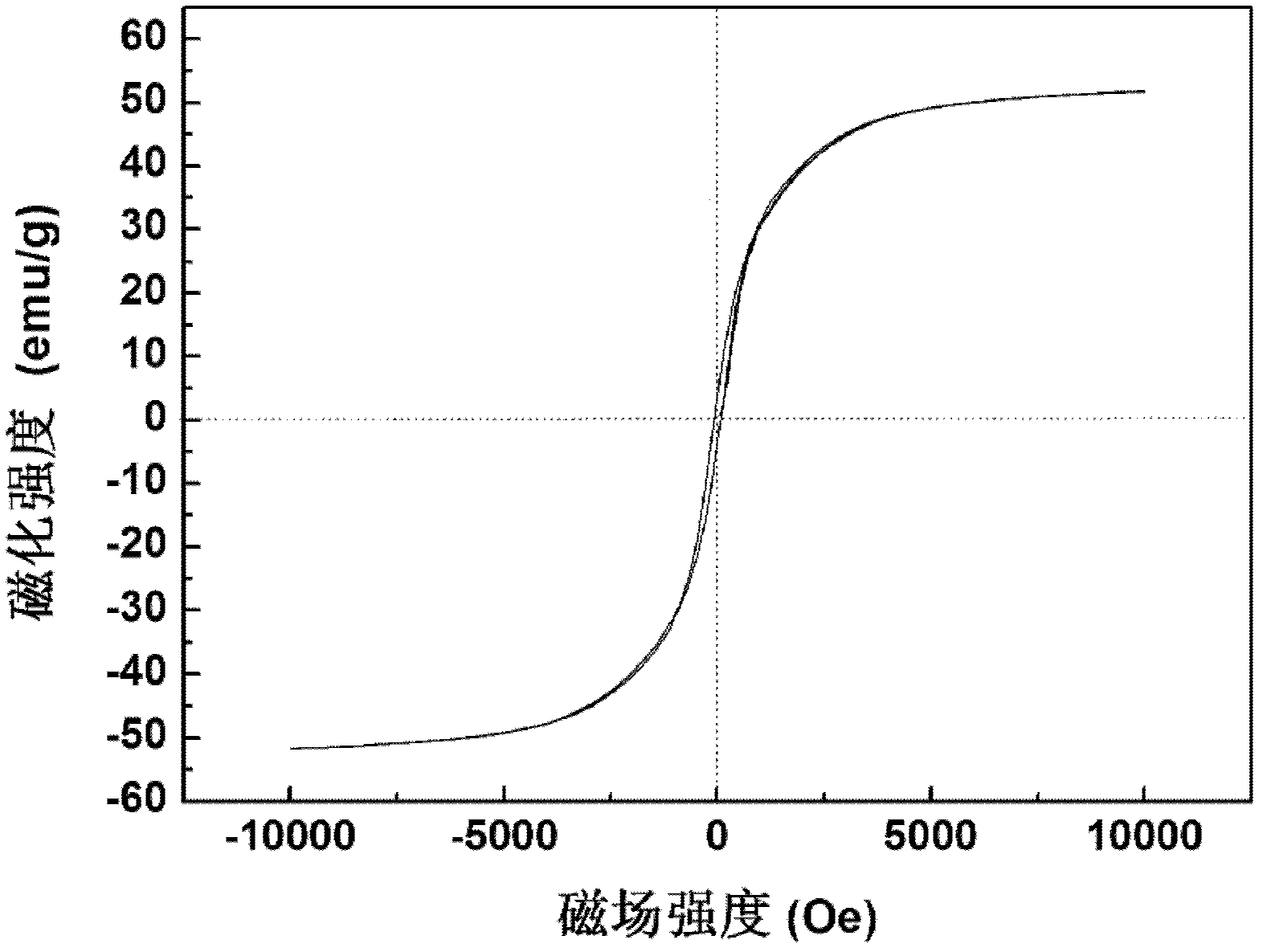

[0027] Weigh 55mg of graphite oxide, put it into a 50ml beaker, add 25ml of ethylene glycol, stir evenly with a glass rod, and then stir for 30min with an ultrasonic stirring power of 200W. Weigh 15.4mg cobalt nitrate hexahydrate, 3.85mg nickel nitrate hexahydrate, 35.8mg ferric chloride hexahydrate, put them into a 50ml beaker, add 25ml ethylene glycol, then add 146mg anhydrous sodium acetate, 1ml polyethylene glycol Diol 200, add magnets, magnetically stir at 300 rpm and stir for 40mim. After complete dissolution, mix the graphite oxide solution and the metal salt solution and continue magnetic stirring at 300 rpm for 40 min. After mixing evenly, the above reaction solution was poured into a reaction kettle, and the temperature was raised to 200° C., and reacted for 12 hours. After the reaction, the product was collected with a magnet, washed with deionized water and absolute ethanol, and then dried at 60 ° C for 12 h to obtain cobalt nickel ferrite (Co 1-x Ni x Fe 2 o ...

Embodiment 2

[0029] Weigh 55mg of graphite oxide, put it into a 50ml beaker, add 18ml of ethylene glycol, stir evenly with a glass rod, and then stir with an ultrasonic stirring power of 200W for 60min. Weigh 77.0mg cobalt nitrate hexahydrate, 19.2mg nickel nitrate hexahydrate, 179mg ferric chloride hexahydrate, add to a 50ml beaker, add 18ml ethylene glycol, then add 810mg anhydrous sodium acetate, 1ml polyethylene glycol 400, Add magnetic sub, magnetic stirring 400 rev / min stirring 40mim. After complete dissolution, mix the graphite oxide solution and the metal salt solution and continue magnetic stirring at 400 rpm for 40 min. After mixing evenly, the above reaction solution was poured into a reaction kettle, and the temperature was raised to 220° C., and reacted for 8 hours. After the reaction, the product was collected with a magnet, washed with deionized water and absolute ethanol, and then dried at 60 ° C for 24 h to obtain cobalt nickel ferrite (Co 1-x Ni x Fe 2 o 4 )(0 figure...

Embodiment 3

[0031] Weigh 55mg of graphite oxide, put it into a 50ml beaker, add 36ml of ethylene glycol, stir evenly with a glass rod, and then stir with an ultrasonic stirring power of 300W for 60min. Weigh 38.5mg cobalt nitrate hexahydrate, 57.7mg nickel nitrate hexahydrate, 179mg ferric chloride hexahydrate, put them into a 50ml beaker, add 36ml ethylene glycol, then add 1.1g anhydrous sodium acetate, 0.6ml polyethylene glycol Alcohol 600, add magnets, magnetically stir at 500 rpm and stir for 30mim. After complete dissolution, mix the graphite oxide solution and the metal salt solution and continue magnetic stirring at 500 rpm for 30 min. After mixing evenly, the above reaction solution was poured into the reaction kettle, and the temperature was raised to 180° C., and reacted for 16 hours. After the reaction, the product was collected with a magnet, washed with deionized water and absolute ethanol, and then dried at 70 ° C for 18 h to obtain cobalt nickel ferrite (Co 1-x Ni x Fe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com