N-doped graphene/nickel ferrite nanometer compound material and preparation thereof

A nitrogen-doped graphene, nanocomposite material technology, applied in nanotechnology, nanotechnology, hybrid/electric double layer capacitor manufacturing and other directions, can solve the problem that the electrochemical performance cannot meet the requirements of practical applications, the electrochemical performance is not ideal, The equipment required for the reaction is complex and other problems, so as to improve the electrochemical performance, facilitate low-cost large-scale production, and achieve the effect of excellent electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

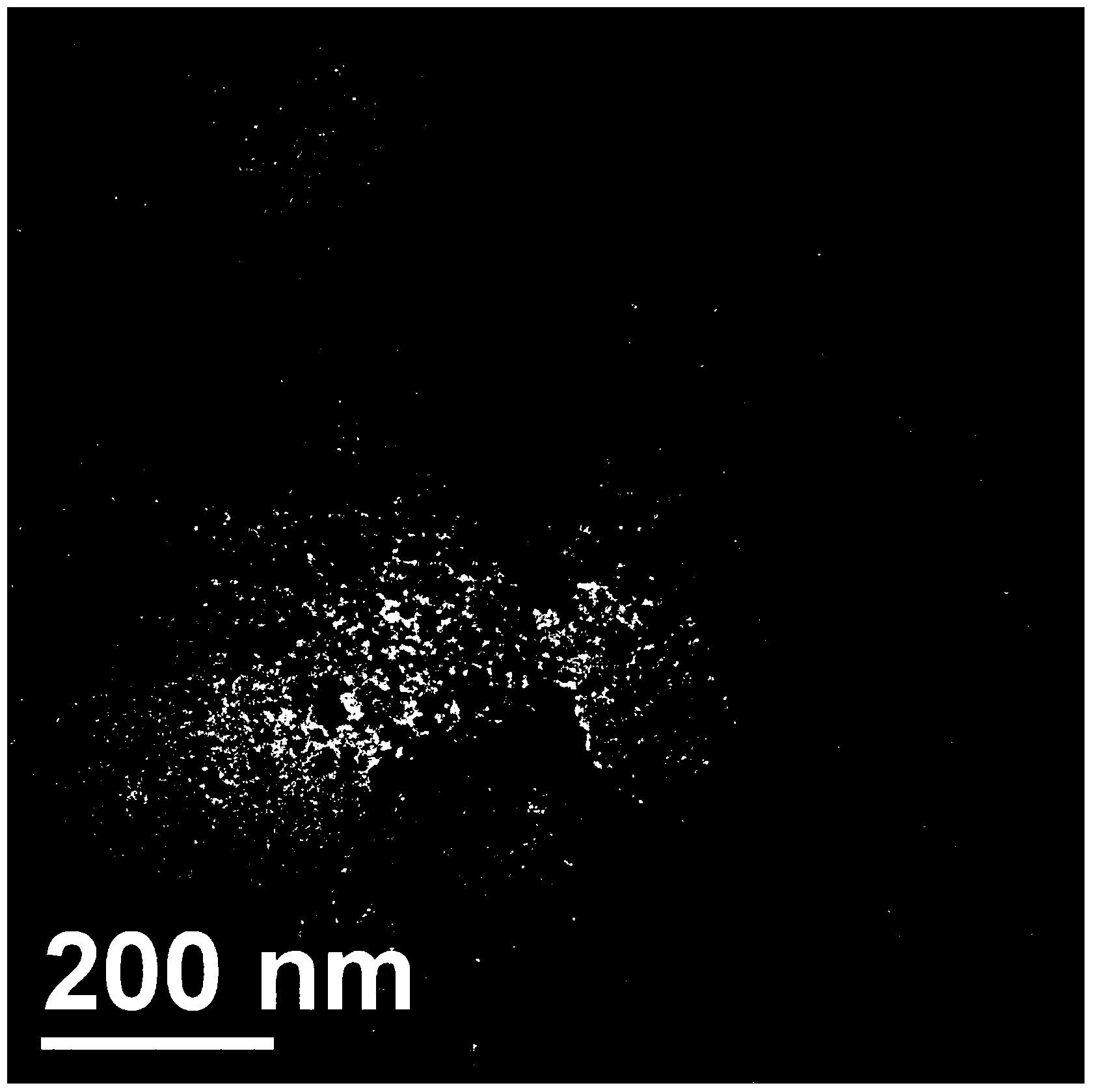

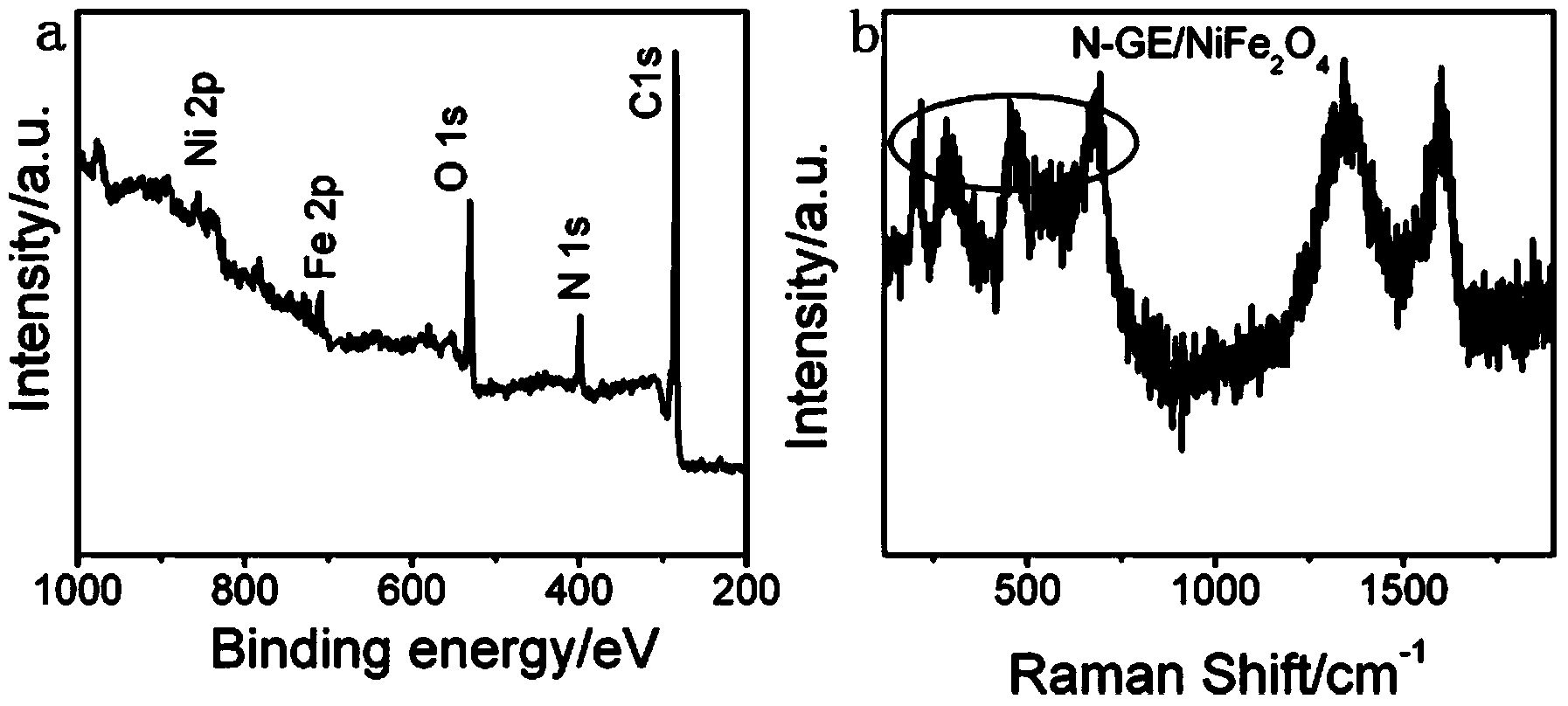

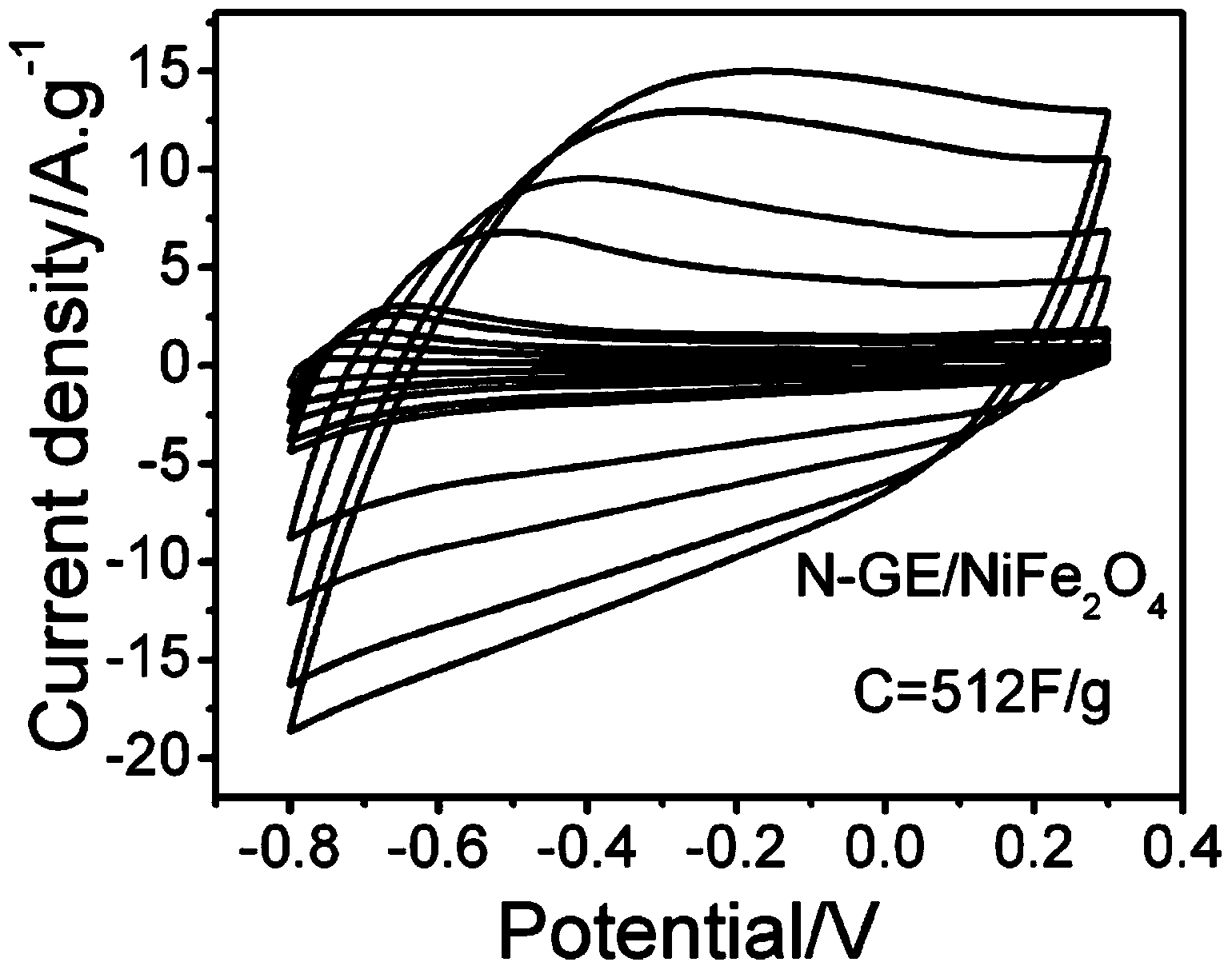

[0022] Implementation example 1: the preparation method of a nitrogen-doped graphene / nickel ferrite nanocomposite material (the mass ratio of graphite oxide to nickel ferrite is 1:1) with a nitrogen content of 1%, comprising the following steps:

[0023] In the first step, ultrasonically disperse graphite oxide with a content of 100mg in 200mL deionized water to obtain a uniform graphene oxide solution, and the ultrasonic time is 2h;

[0024] In the second step, 0.3453g of ferric nitrate and 0.1243g of nickel nitrate were added to the uniformly dispersed solution, and stirred for 30min;

[0025] In the third step, add 10 g of urea into the mixed system obtained in the second step, and stir again for 30 minutes to make it evenly dispersed;

[0026] Step 4: Transfer the uniformly mixed solution above to a three-necked flask, the temperature of the oil bath is 150°C, and the reaction time is 16 hours;

[0027] Step 5: Centrifuge the reacted product, wash it with deionized water ...

Embodiment 2

[0029] Implementation example 2: the preparation method of a nitrogen-doped graphene / nickel ferrite nanocomposite material (the mass ratio of graphite oxide to nickel ferrite is 1:10) with a nitrogen content of 2%, comprising the following steps:

[0030] In the first step, ultrasonically disperse graphite oxide with a content of 50 mg in 100 mL of deionized water to obtain a uniform graphene oxide solution, and the ultrasonic time is 1 h;

[0031] In the second step, 1.7266g of ferric nitrate and 0.6214g of nickel nitrate were added to the uniformly dispersed solution, and stirred for 10min;

[0032] In the third step, add 10 g of urea into the mixed system obtained in the second step, and stir again for 60 minutes to make it evenly dispersed;

[0033] Step 4: Transfer the above-mentioned homogeneously mixed mixed solution to a three-necked flask, the temperature of the oil bath is 100°C, and the reaction time is 20h;

[0034] Step 5: Centrifuge the reacted product, wash it ...

Embodiment 3

[0036] Implementation example 3: the preparation method of a nitrogen-doped graphene / nickel ferrite nanocomposite material (the mass ratio of graphite oxide to nickel ferrite is 1:5) with a nitrogen content of 1.5%, comprising the following steps:

[0037] In the first step, ultrasonically disperse graphite oxide with a content of 100mg in 100mL deionized water to obtain a uniform graphene oxide solution, and the ultrasonic time is 4h;

[0038] In the second step, 1.7266g of ferric nitrate and 0.6214g of nickel nitrate were added to the uniformly dispersed solution, and stirred for 60min;

[0039] In the third step, 15g of urea was added to the mixed system obtained in the second step, and stirred again for 90 minutes to make it uniformly dispersed;

[0040] Step 4: Transfer the uniformly mixed solution above to a three-necked flask, the temperature of the oil bath is 200°C, and the reaction time is 12 hours;

[0041] Step 5: Centrifuge the reacted product, wash it with deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com