Magnetic reduction graphene oxide nano composite material and preparation method and application thereof

A nanocomposite material and graphene technology, which is applied in the field of magnetically reduced graphene oxide nanocomposite materials and its preparation, can solve the problems of poor microwave absorption performance, cumbersome preparation process, and many reaction reagents, so as to improve microwave absorption performance, The process is simple and the effect of improving the effective absorption bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention provides a kind of preparation method of magnetically reduced graphene oxide nanocomposite material in second aspect, described method comprises the steps:

[0037] (1) graphene oxide is uniformly dispersed with deionized water to obtain a graphene oxide dispersion;

[0038] (2) adding divalent nickel salt and ferric salt to the graphene oxide dispersion obtained in step (1) and stirring evenly to obtain the first mixed solution;

[0039] (3) adding ammonia water to the first mixed solution obtained in step (2) to adjust the first mixed solution to alkaline to obtain a second mixed solution;

[0040] (4) carry out hydrothermal treatment to the described second mixed solution that step (3) obtains, make magnetic reduction graphene oxide nanocomposite material (NiFe 2 o 4 / r-GO nanocomposites).

[0041] It should be noted that the terms "first", "second" and so on are only used for descriptive purposes, and should not be understood as indicating o...

Embodiment 1

[0063] S1. Disperse graphene oxide with a content of 20mg in 30mL deionized water, and perform ultrasonic treatment for 2h; centrifuge the dispersed graphene oxide mixture after ultrasonic treatment, the speed is 3000r / min, and the centrifugation time is 3min. Take the supernatant to obtain a uniformly dispersed graphene oxide dispersion.

[0064] S2. Add 0.122g of ferric nitrate nonahydrate and 0.0435g of nickel nitrate hexahydrate to the above-mentioned uniformly dispersed graphene oxide dispersion, and stir fully at room temperature on a magnetic stirrer for 30 minutes until completely dissolved , to obtain the first mixture.

[0065] S3. Add ammonia water dropwise to the first mixed solution obtained in S2, stir well to make it evenly mixed, adjust the pH value of the first mixed solution to 10, and obtain a second mixed solution.

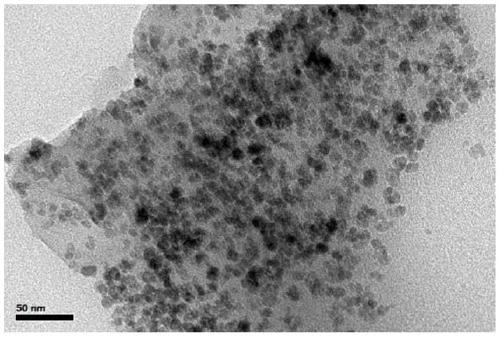

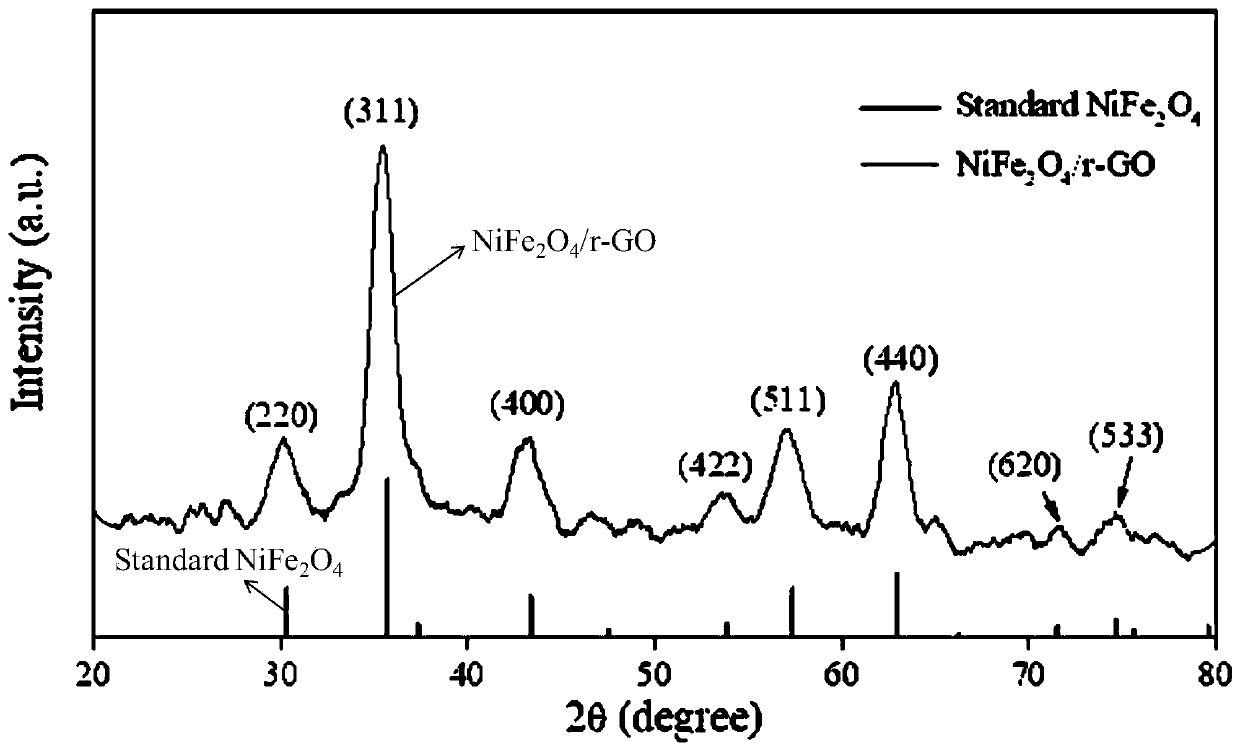

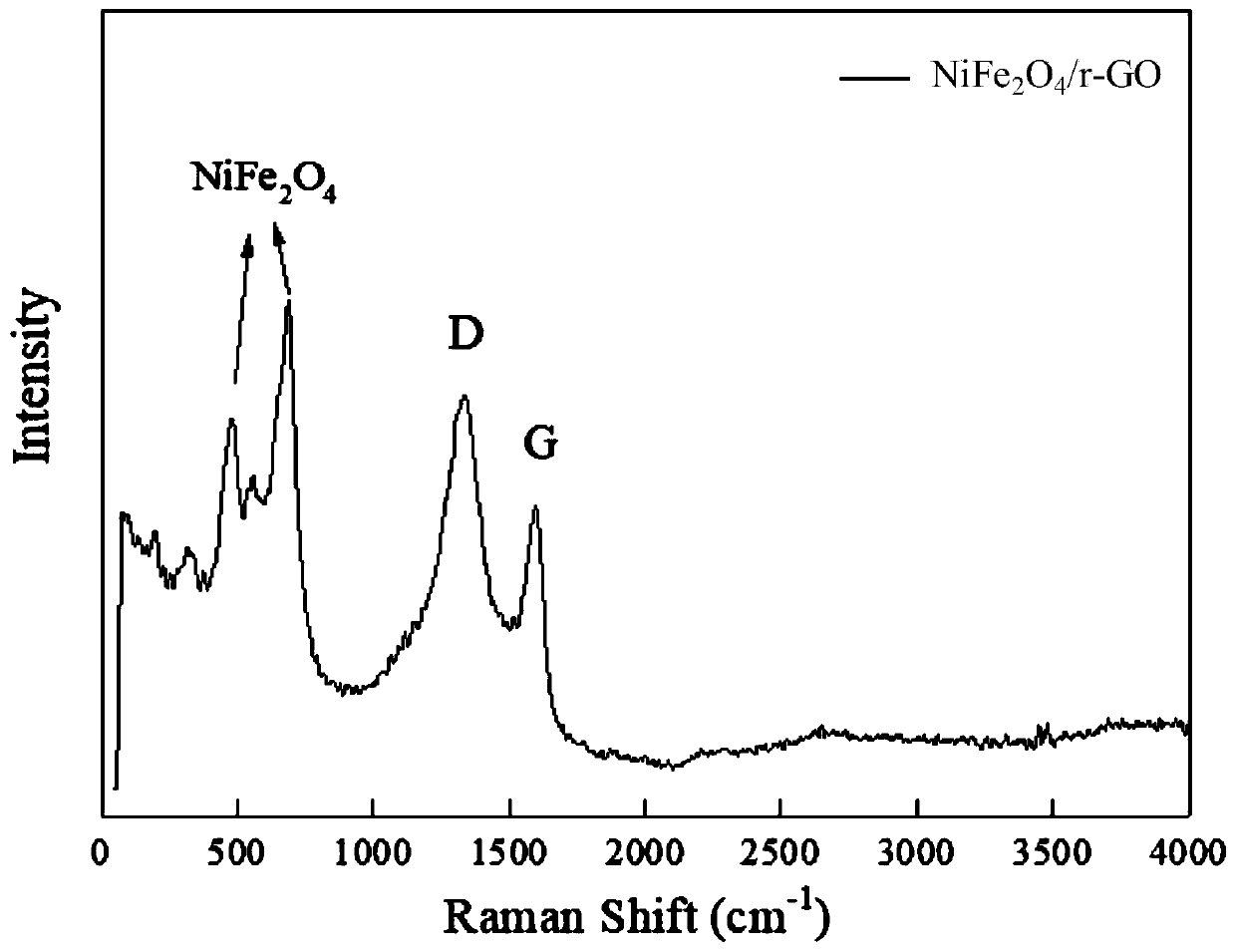

[0066] S4. Transfer the uniform second mixed solution obtained in S3 to a 50 mL polytetrafluoroethylene-lined reactor for hydrothermal treatm...

Embodiment 2

[0070] S1. Disperse graphene oxide with a content of 20mg in 30mL deionized water, and perform ultrasonic treatment for 2h; centrifuge the dispersed graphene oxide mixture after ultrasonic treatment, the speed is 3000r / min, and the centrifugation time is 3min. Take the supernatant to obtain a uniformly dispersed graphene oxide dispersion.

[0071] S2. Add 0.624g of ferric nitrate nonahydrate and 0.223g of nickel nitrate hexahydrate to the above-mentioned uniformly dispersed graphene oxide dispersion, and stir fully at room temperature on a magnetic stirrer for 30 minutes until completely dissolved , to obtain the first mixture.

[0072] S3. Add ammonia water dropwise to the first mixed solution obtained in S2, stir well to make it evenly mixed, adjust the pH value of the first mixed solution to 10, and obtain a second mixed solution.

[0073] S4. Transfer the uniform second mixed solution obtained in S3 to a 50 mL polytetrafluoroethylene-lined reactor for hydrothermal treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com