Nickel ferrite nano-particle electrode material, preparation method and use

A nanoparticle and electrode material technology, which is applied in the direction of nanotechnology, nanotechnology, hybrid capacitor electrodes, etc., can solve the problems of low safety, high Faraday pseudocapacitance, poor oxidation resistance, etc., and achieve stable physical and chemical properties. The effect of mass production and low migration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

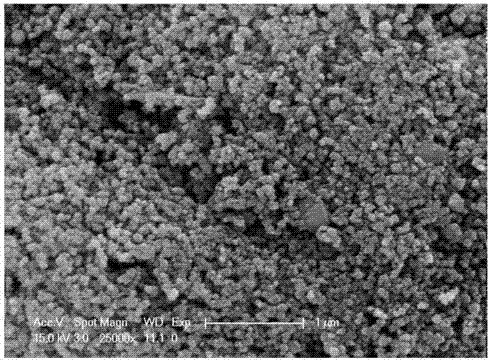

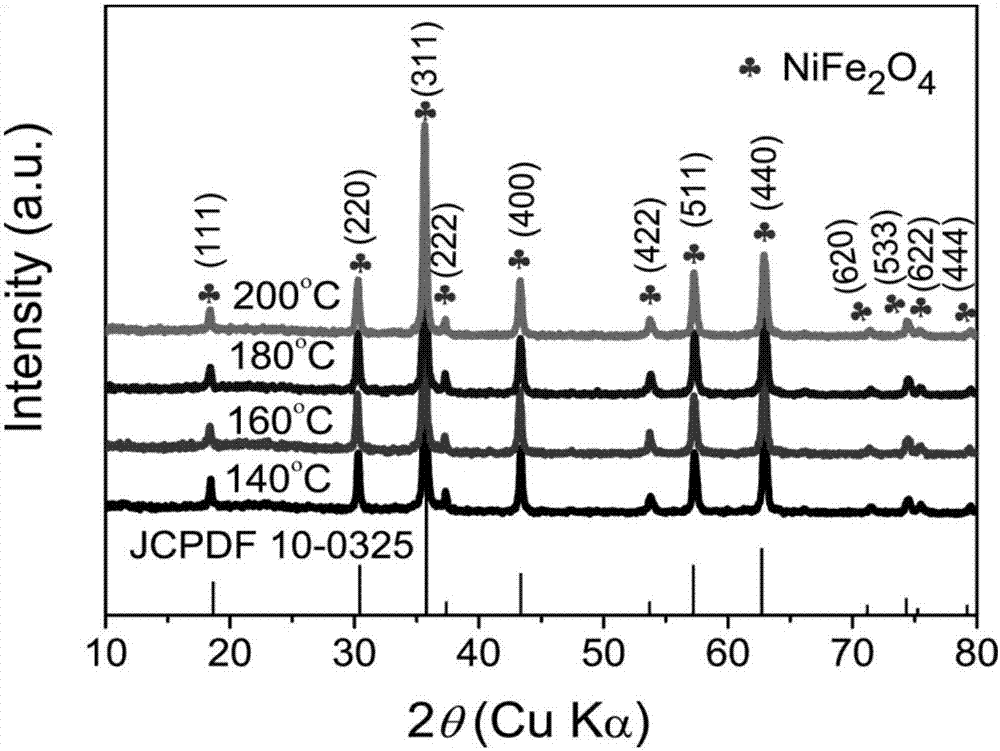

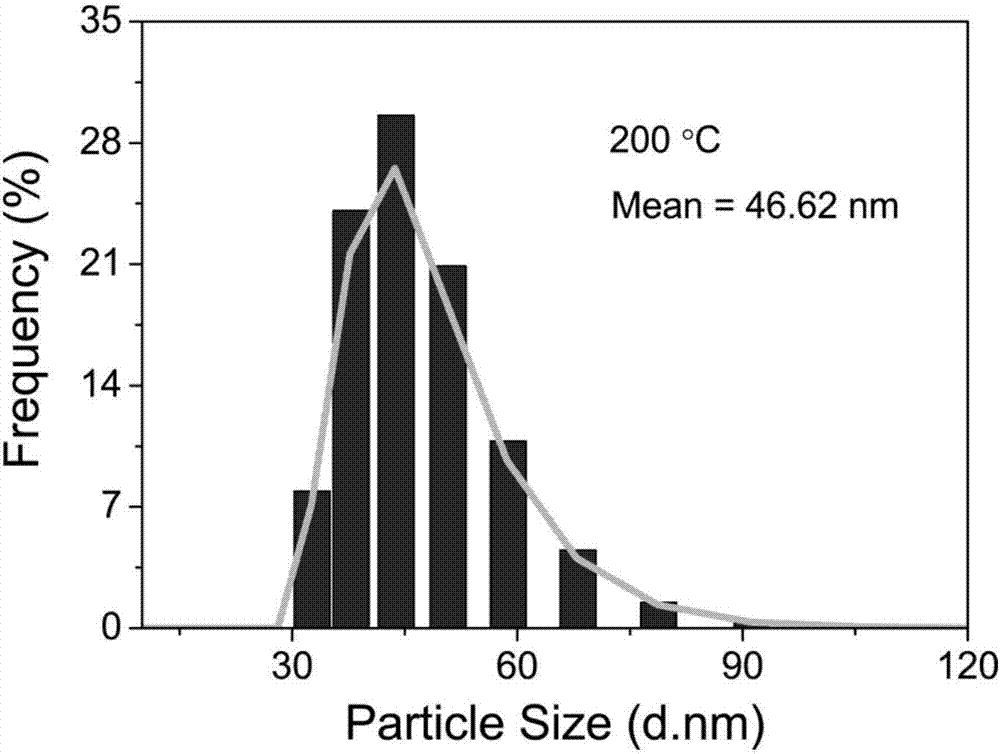

[0030] Add 2mmol of nickel chloride, 1mmol of ferric nitrate, 6mmol of hexamethylenetetramine, and 5mmol of ammonium fluoride powder into 80ml of distilled water, put it in a 100ml beaker, put it into an ultrasonic instrument for 5 minutes, and stir it with a magnetic stirrer Let it mix well for 30 minutes. Pour the above solution into a 100ml polytetrafluoroethylene-lined reaction kettle, seal it, place it in an oven, control the temperature of the oven at 200°C, react for 10 hours, cool to room temperature, wash it several times, and dry it in vacuum to obtain iron Nickel nanoparticles. The obtained nickel ferrite nanoparticles are evenly mixed with acetylene black and polytetrafluoroethylene in a certain mass ratio of 8:1:1 to obtain a thick slurry, and then all the slurry is applied to the foamed nickel sheet, and finally heated at 150 degrees Dry for 3 hours and cool to room temperature to obtain nickel ferrite nanoparticle electrode material. figure 1 The positions and...

Embodiment 2

[0032] Add 2mmol of ferric nitrate, 1mmol of nickel acetate, 10mmol of hexamethylenetetramine, and 5mmol of ammonium fluoride powder into 80ml of distilled water, put it in a 100ml beaker, put it into an ultrasonic instrument for 5 minutes, and stir it with a magnetic stirrer for 30 minutes. minutes to mix well. Pour the above solution into a 100 ml polytetrafluoroethylene-lined reaction kettle, seal it, place it in an oven, control the temperature of the oven at 180°C, react for 12 hours, cool to room temperature, wash it several times, and dry it in vacuum to obtain Nickel ferrite nanoparticles. The obtained nickel ferrite nanoparticles are uniformly mixed with acetylene black and polytetrafluoroethylene in a certain mass ratio of 7:2:1 to obtain a thick slurry, and then all the slurry is applied to the foamed nickel sheet, and finally heated at 130 degrees Dry for 5 hours and cool to room temperature to obtain nickel ferrite nanoparticle electrode material.

Embodiment 3

[0034] Add 2mmol of nickel chloride, 2mmol of ferric nitrate, 3mmol of hexamethylenetetramine, and 10mmol of ammonium fluoride powder into 80ml of distilled water, put it in a 100ml beaker, put it into an ultrasonic instrument for 5 minutes, and stir it with a magnetic stirrer Let it mix well for 30 minutes. Pour the above solution into a 100ml polytetrafluoroethylene-lined reaction kettle, seal it, place it in an oven, control the temperature of the oven at 160°C, react for 6 hours, cool to room temperature, wash it several times, and dry it in vacuum to obtain iron Nickel nanoparticles. The obtained nickel ferrite nanoparticles are uniformly mixed with acetylene black and polytetrafluoroethylene in a certain mass ratio of 8:1:1 to obtain a thick slurry, and then all the slurry is applied to the foamed nickel sheet, and finally heated at 100 degrees Dry for 6 hours and cool to room temperature to obtain nickel ferrite nanoparticle electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com