Preparation method of TiO2/SiO2/NiFe2O4 magnetic composite photocatalyst

A photocatalyst and composite magnetic technology, which is applied in the field of magnetic photocatalyst material preparation, can solve the problems of reduced photocatalyst activity, lower catalyst specific surface area and mass transfer rate, and achieve the effects of reduced adverse effects, stable properties, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

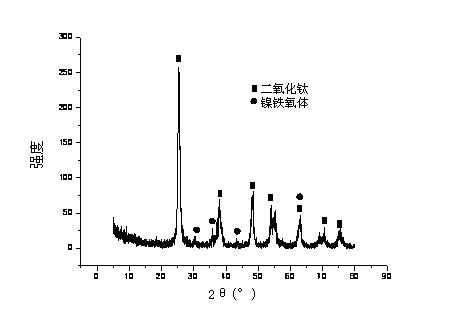

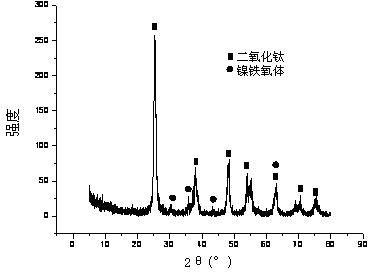

Image

Examples

Embodiment

[0021] Concrete steps in the present embodiment are as follows:

[0022] (1) Preparation of NiFe 2 o 4 : Accurately weigh 3.243g FeCl 3 ·6H 2 O and 1.745g Ni (NO 3 ) 2 ·6H 2 O, dissolve in 80ml of distilled water, add 4ml of 1mol / L hydrazine hydrate solution, and stir evenly. Then adjust the pH value of the mixed solution to about 10 with 5 mol / L sodium hydroxide solution to form a suspension. The suspension was transferred to a 150ml autoclave, the lid was tightened, and placed in a blast drying oven at 180°C for hydrothermal reaction for 8 hours. After the reaction, the autoclave was taken out, cooled rapidly, and then the product was transferred to a 500ml beaker, washed with distilled water until neutral, filtered with suction, and then dried in an air-blast drying oven at 80°C for 3 hours, and ground to obtain Magnetic NiFe 2 o 4 powder.

[0023] (2), preparation of SiO 2 / NiFe 2 o 4 : Accurately weigh 0.56g of nickel ferrite powder and add it to 20ml of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com