Preparation method of nickel ferrite magnetic nanofiber material

A technology of magnetic nano and fiber materials, applied in the field of nano materials, can solve the problems affecting large-scale production and application, easy agglomeration of materials, complex preparation process, etc., and achieve the effect of high yield, low preparation temperature and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

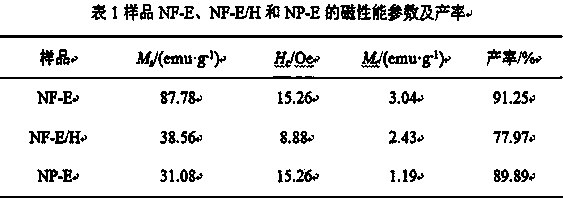

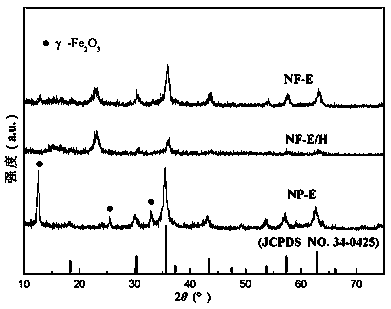

Embodiment 1

[0031] 0.5863 g Ni(NO 3 ) 2 ·6H 2 O and 1.6289 g Fe(NO 3 ) 3 9H 2 O(Ni 2+ , Fe 3+ 1:2) was dissolved in 48 mL of absolute ethanol to form a solution; 1.0000 g of cotton fibers were immersed in the solution, and ultrasonicated for 0.5 h; Under reaction for 10 h. After draining the solution, dry it in an oven at 100°C for 10 h to obtain NiFe 2 o 4 nanofiber material. The yield was 91.25%. sample M s = 87.78 emu g -1 , H c =15.26 Oe, M r = 3.04 emu g -1 .

Embodiment 2

[0033] 0.5863 g Ni(NO 3 ) 2 ·6H 2 O and 1.6289 g Fe(NO 3 ) 3 9H 2 O(Ni 2+ , Fe 3+ 1:2) was dissolved in 48 mL of absolute ethanol to form a solution; 1.0000 g of cotton fiber was immersed in the solution, and ultrasonicated for 0.5 h; Under reaction 8 h. After draining the solution, dry it in an oven at 100°C for 10 h to obtain NiFe 2 o 4 nanofiber material. The yield was 81.25%. sample M s = 76.82 emu g -1 , H c =14.36 Oe, M r = 4.05 emu g -1 .

Embodiment 3

[0035] 0.5863 g Ni(NO 3 ) 2 ·6H 2 O and 1.6289 g Fe(NO 3 ) 3 9H 2 O(Ni 2+ , Fe 3+ The ratio of the amount of the substance is 1:2) dissolved in 48 mL of absolute ethanol to form a solution; 1.0000 g of cotton fibers were immersed in the solution, ultrasonicated for 0.5 h; Under reaction for 12 h. After draining the solution, dry it in an oven at 100°C for 10 h to obtain NiFe 2 o 4 nanofiber material. The yield was 89.13%. sample M s = 80.13 emu g -1 , H c =35.26 Oe, M r = 5.17 emu g -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com