Nitrogen-doped graphene nickel ferrite composite wave-absorbing material and preparation method thereof

A composite wave absorbing material, nitrogen doping technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor impedance matching of RGO, low electromagnetic wave absorption ability, difficult to meet commercial applications, etc., and achieves low matching thickness, Excellent absorbing performance and strong absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

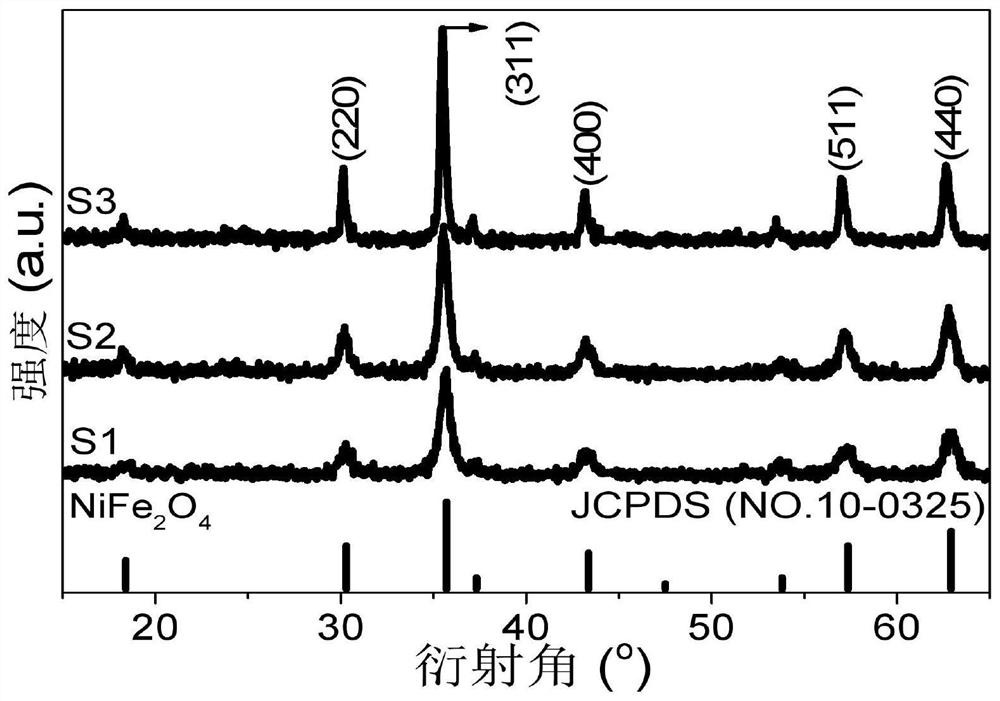

Embodiment 1

[0048] The method steps for the preparation of the nitrogen-doped graphene-nickel-ferrite composite wave-absorbing material proposed by the present invention are as follows:

[0049] S1: Add 120 mL of deionized water and 90 mg of graphene oxide into the container, stir for 10 minutes and then sonicate for 30 minutes to prepare a graphene oxide aqueous dispersion with a concentration of 0.75 mg / mL;

[0050] S2: Add 1.616g (4mmol) iron nitrate nonahydrate (Fe(NO) to the dispersion described in S1 3 ) 3 9H 2 O) and 0.582g (2mmol) nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 0), stirring 10min makes it dissolve completely, obtains uniform transparent dispersion liquid, then adds 2.7g sodium acetate, stirs 15min to fully dissolving;

[0051] S3: Add 0.75 g of polyethylene glycol to the solution of S2, stir in a water bath at 50°C to dissolve it;

[0052] S4: Add 5 mL of hydrazine hydrate to the solution of S3, and stir for 10 minutes to obtain a uniform dispersion. After mix...

Embodiment 2

[0056] The method steps for the preparation of the nitrogen-doped graphene-nickel-ferrite composite wave-absorbing material proposed by the present invention are as follows:

[0057] S1: Add 120 mL of deionized water and 90 mg of graphene oxide into the container, stir for 10 minutes and then sonicate for 30 minutes to prepare a graphene oxide aqueous dispersion with a concentration of 0.75 mg / mL;

[0058] S2: Add 1.616g (4mmol) iron nitrate nonahydrate (Fe(NO) to the dispersion described in S1 3 ) 3 9H 2 O) and 0.582g (2mmol) nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 0), stirring 10min makes it dissolve completely, obtains uniform transparent dispersion liquid, then adds 2.7g sodium acetate, stirs 15min to fully dissolving;

[0059] S3: Add 0.75 g of polyethylene glycol to the solution of S2, stir in a water bath at 50°C to dissolve it;

[0060] S4: Add 10 mL of hydrazine hydrate to the solution of S3, and stir for 10 minutes to obtain a uniform dispersion. After mi...

Embodiment 3

[0064] The method steps for the preparation of the nitrogen-doped graphene-nickel-ferrite composite wave-absorbing material proposed by the present invention are as follows:

[0065] S1: Add 120 mL of deionized water and 90 mg of graphene oxide into the container, stir for 10 minutes and then sonicate for 30 minutes to prepare a graphene oxide aqueous dispersion with a concentration of 0.75 mg / mL;

[0066] S2: Add 1.616g (4mmol) iron nitrate nonahydrate (Fe(NO) to the dispersion described in S1 3 ) 3 9H 2 O) and 0.582g (2mmol) nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 0), stirring 10min makes it dissolve completely, obtains uniform transparent dispersion liquid, then adds 2.7g sodium acetate, stirs 15min to fully dissolving;

[0067] S3: Add 0.75 g of polyethylene glycol to the solution of S2, stir in a water bath at 50°C to dissolve it;

[0068] S4: Add 15 mL of hydrazine hydrate to the solution of S3, and stir for 10 minutes to obtain a uniform dispersion. After mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com