Roller type bearing spinning closing-in device and using method thereof

A closing device and roller-type technology, which is applied in the field of bearing closing in the assembly of aviation small components, can solve the problems of poor closing efficiency of double vertical roulettes, heavy workload requirements for workers, and difficulty in guaranteeing machining accuracy, so as to reduce manufacturing difficulty and process The effect of technical operability, avoiding repeated clamping, and simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

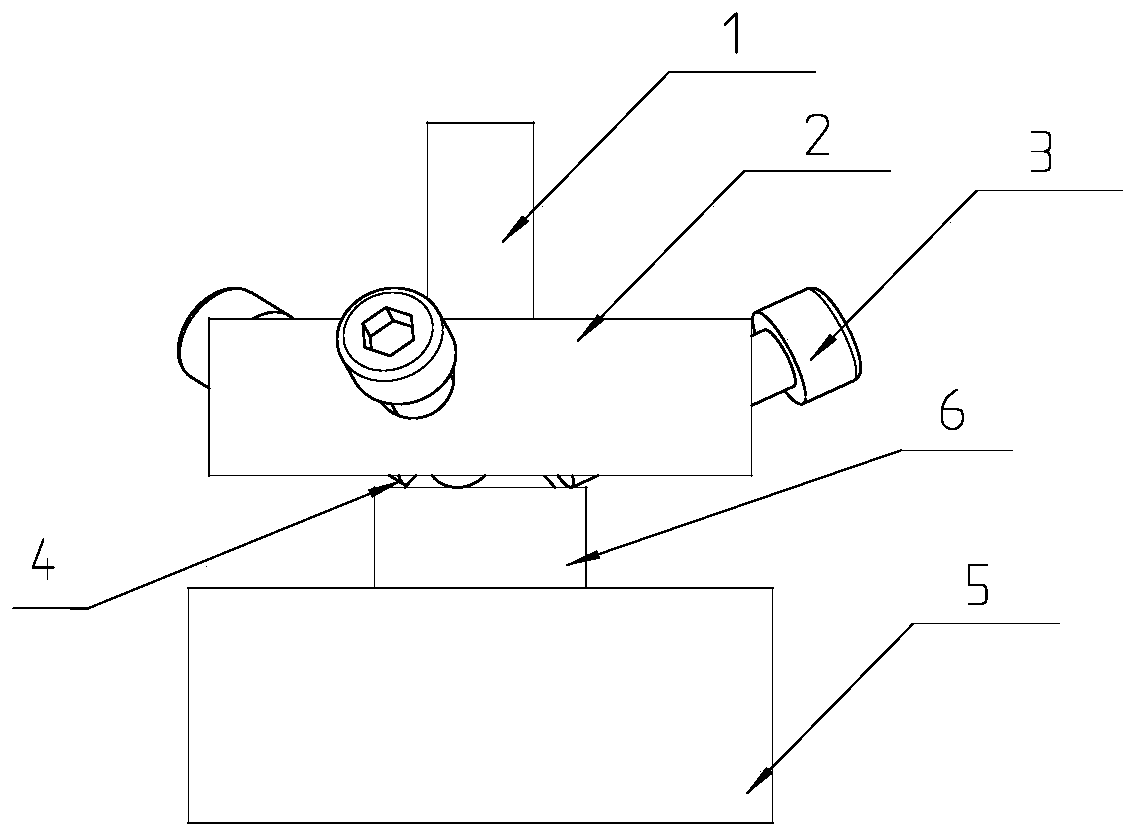

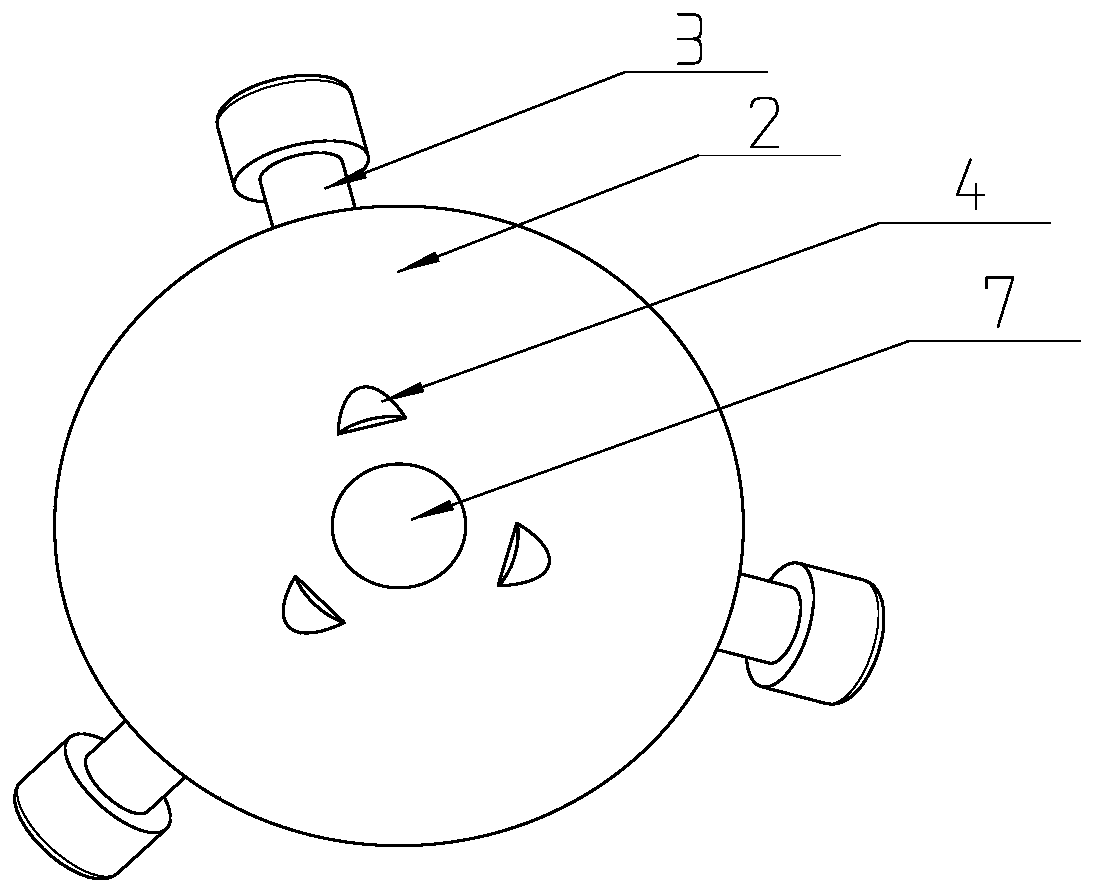

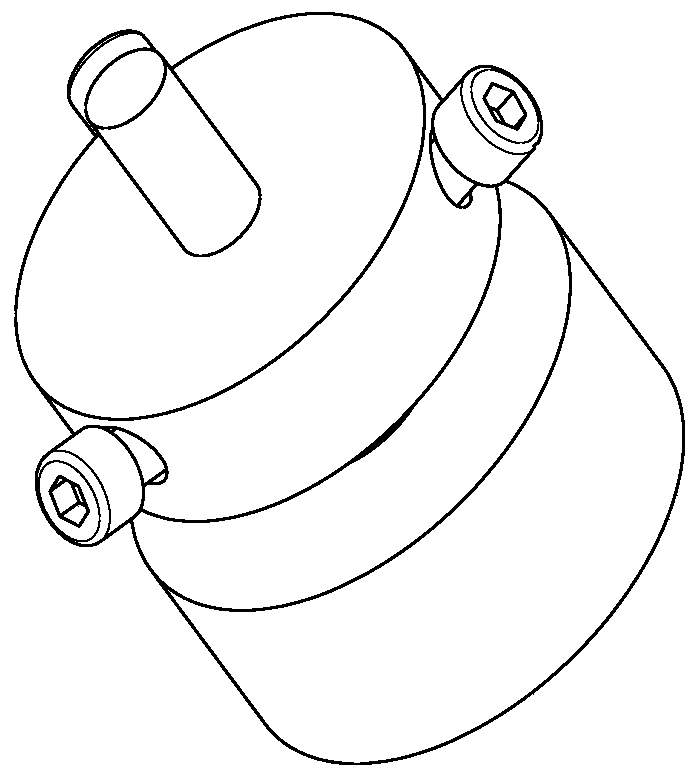

[0026] A roller type bearing spinning mouth closing device, such as Figure 1-3 As shown, it includes tool handle 1, spinning head 2, embedded bolt 3, bolt rod 4, circular frame seat 5, guide shaft 7, tool handle 1 is vertically fixed at the middle position above spinning head 2, and spinning head 2 There are three bolt holes on the side, the bolt holes and the horizontal plane form an angle of 25°, the bolt holes run through the spinning head 2, and the bolt holes are distributed at an equal angle with the central axis of the spinning head 2 as the axis; There is a guide shaft 7, and the guide shaft 7 and the spinning head 2 are installed in cold shrinkage, with interference fit, and the joints are sealed with glue; a circular frame seat 5 is arranged under the spinning head 2.

[0027] The guide shaft 7 is a cylinder, the outer diameter of the guide shaft 7 matches the size of the inner hole of the bearing to be processed, and the length of the guide shaft 7 matches the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com