Preparation method of environment-friendly pigment yellow 151

A kind of pigment yellow, environment-friendly technology, applied in the preparation of pigment yellow 151 prepared by reacting with water bath heating in the preparation of intermediates, the preparation field of environment-friendly pigment yellow 151, can solve the support that cannot be differentiated, poor support stability, base area Limited and other problems, to achieve the effect of simple use and discharge, sufficient response, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

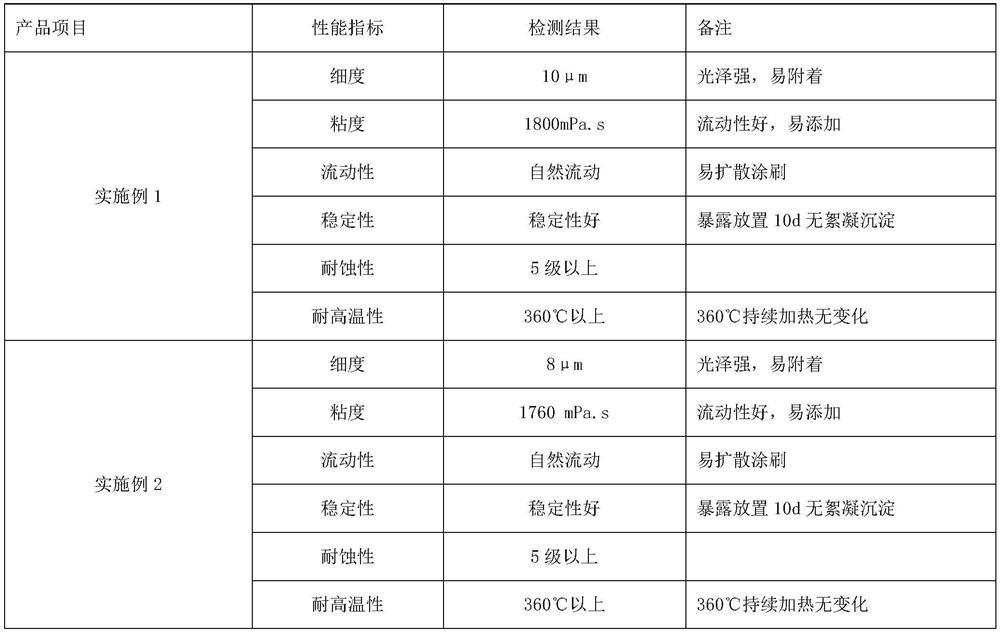

Embodiment 1

[0028] The preparation method of a kind of environment-friendly pigment yellow 151 of the present invention is realized in this way, the preparation method of a kind of environment-friendly pigment yellow 151 of the present invention:

[0029] 2) Intermediate preparation:

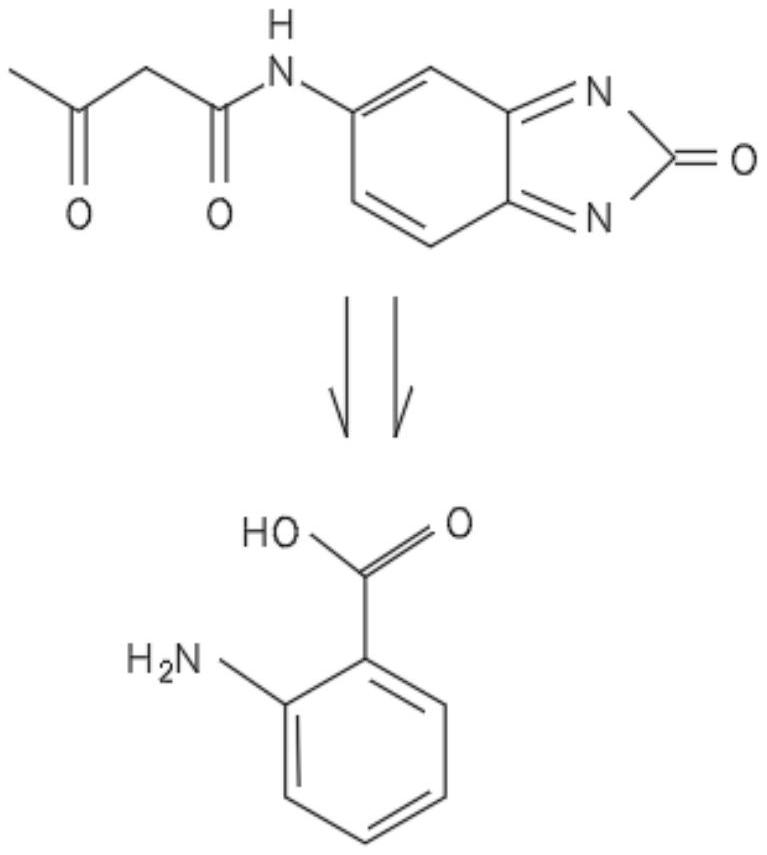

[0030] 1.1 Using o-phenylenediamine and urea as raw materials to condense in an aqueous medium, a light purple flaky crystal-benzimidazolone was obtained. After condition optimization, the yield was 96.01% and the purity was 99.90%;

[0031] 1.2 Nitrate with concentrated nitric acid in the organic solvent chlorobenzene to obtain dark green spherical solid-5-nitrobenzimidazolone with a yield of 98.60% and a purity of 99.20%;

[0032] 1.3 Then use absolute ethanol as solvent and skeleton nickel as catalyst to carry out liquid phase hydrogenation reduction reaction to obtain -5-aminobenzimidazolone (ABI). After condition optimization, the yield is 94.14% and the purity is 99.90%. ;

[0033] 1.4 Finally, dike...

Embodiment 2

[0044] The preparation method of a kind of environment-friendly pigment yellow 151 of the present invention is realized in this way, the preparation method of a kind of environment-friendly pigment yellow 151 of the present invention:

[0045] 3) Intermediate preparation:

[0046] 1.1 Using o-phenylenediamine and urea as raw materials to condense in an aqueous medium, a light purple flaky crystal-benzimidazolone was obtained. After condition optimization, the yield was 96.01% and the purity was 99.90%;

[0047] 1.2 Nitrate with concentrated nitric acid in the organic solvent chlorobenzene to obtain dark green spherical solid-5-nitrobenzimidazolone with a yield of 98.60% and a purity of 99.20%;

[0048] 1.3 Then use absolute ethanol as solvent and skeleton nickel as catalyst to carry out liquid phase hydrogenation reduction reaction to obtain -5-aminobenzimidazolone (ABI). After condition optimization, the yield is 94.14% and the purity is 99.90%. ;

[0049] 1.4 Finally, dike...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com