Ultrathin lithium-manganese polymer battery and processing method thereof

A polymer, ultra-thin lithium technology, used in lithium batteries, battery electrodes, battery pack components, etc., can solve problems such as unfavorable improvement of electrode output current density, positive electrode active material affecting battery capacity, high binder resistivity, etc. problems, to achieve stable battery performance and good storage performance, reduce welding, and reduce the effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

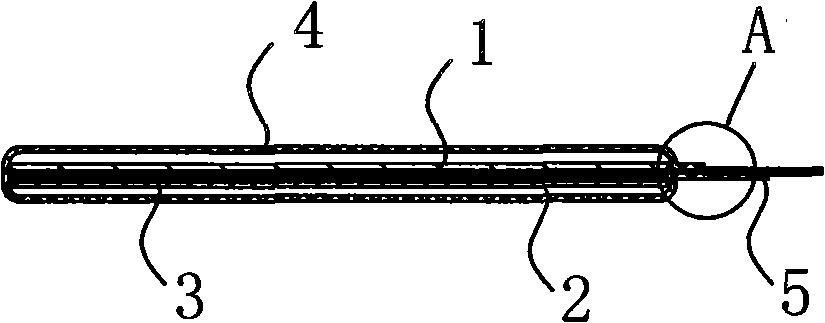

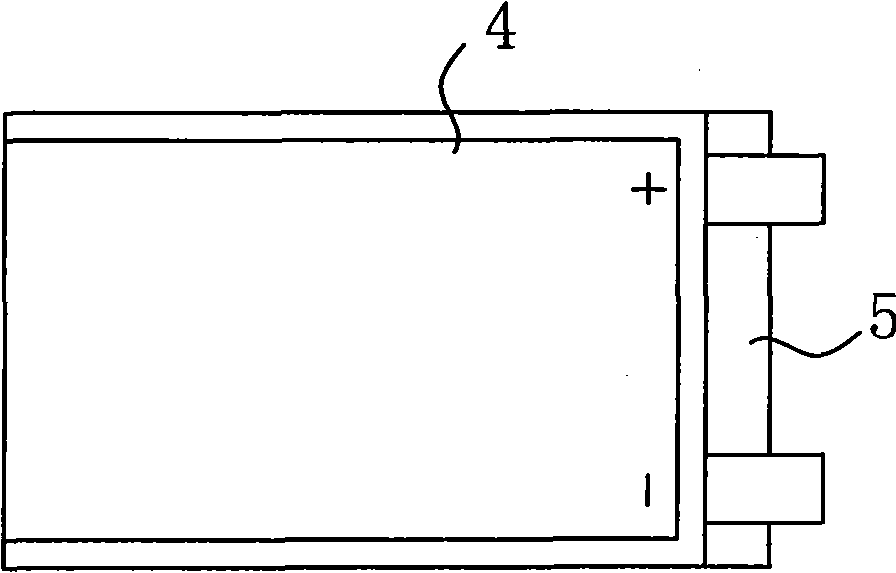

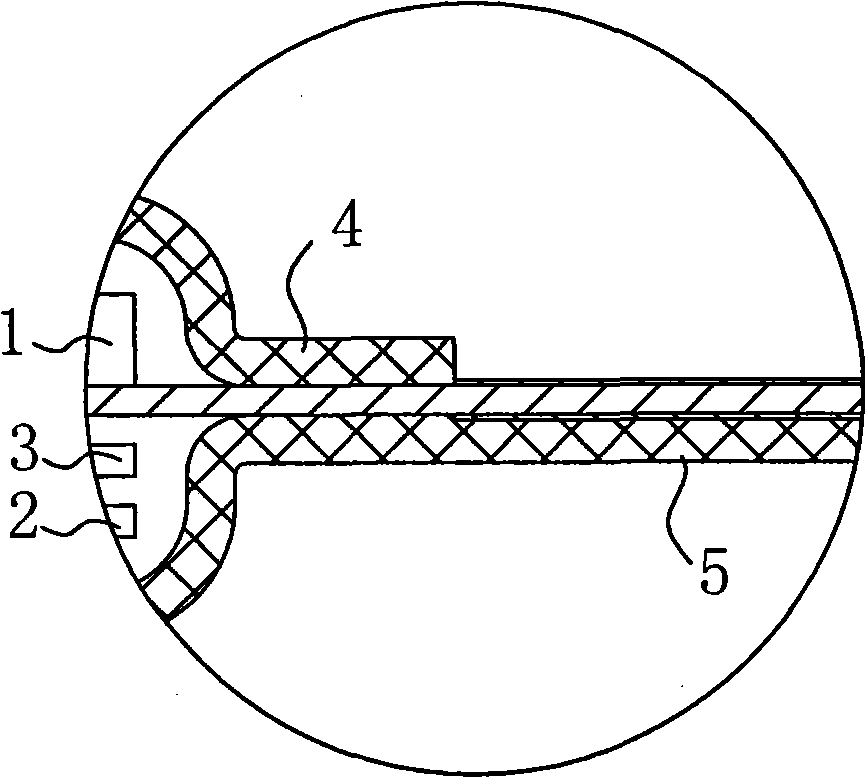

[0036] refer to Figures 1 to 3 As shown, a kind of ultra-thin lithium-manganese polymer battery of the present invention comprises battery body, and battery body is positive electrode 1, negative electrode 2, diaphragm 3 and outer packaging film 4, and positive electrode is made of 10 μ m current collector aluminum foil, manganese dioxide, conductive The thickness of the positive electrode is 0.1 mm, which is equivalent to 90 μm after coating and rolling; the tab of the positive electrode 1 in this embodiment is formed by the extension of the current collector aluminum foil outside the outer packaging film 4 and compounded with polymer Composed of propylene; the negative electrode 2 is made up of a metal lithium sheet and a nickel strip, and the tab of the negative pole 2 is composed of an extension of the nickel strip outside the outer packaging film 4 and composite polypropylene; the overall thickness of the battery is about 0.30mm; in this embodiment, the two The weight ra...

Embodiment 2

[0038] refer to Figure 4 to Figure 6As shown, the present invention includes positive electrode 1, negative electrode 2, separator 3 and outer packaging film 4. The positive electrode is composed of 50 μm current collector aluminum foil, manganese dioxide, conductive agent and binder. The thickness of the positive electrode is 0.2mm, which is equivalent to The thickness after coating and rolling is 150 μm; the tab of the positive electrode 1 in this embodiment is composed of the extension of the current collector aluminum foil outside the outer packaging film 4 and compounded with polyethylene; the negative electrode 2 is composed of metal lithium sheet and copper strip, and the negative electrode 2 The tabs are formed by the extension of the copper tape outside the outer packaging film 4 and composite polyethylene; the overall thickness of the battery is about 0.50mm; the weight ratio of manganese dioxide in this embodiment is 95%; the weight ratio of the conductive agent is ...

Embodiment 3

[0040] refer to Figure 7 to Figure 9 As shown, an ultra-thin lithium-manganese polymer battery of the present invention includes a positive electrode 1, a negative electrode 2, a separator 3 and an outer packaging film 4, and the positive electrode is composed of a 30 μm current collector aluminum foil, manganese dioxide, a conductive agent and a binder , the thickness of the positive electrode is 0.18 mm, which is equivalent to a thickness of 150 μm after coating and rolling; the tab of the positive electrode 1 in this embodiment is composed of the extension of the current collector aluminum foil outside the outer packaging film 4 and composite polypropylene; the negative electrode 2 is composed of Metal lithium sheet and steel belt are made up, and the tab of negative electrode 2 is made up of steel belt outside the extension of outer packaging film 4 and composite polypropylene; The overall thickness of battery is about 0.40mm; The weight ratio of manganese dioxide in the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com