Semiconductor module and method for mfg. semiconductor module

A semiconductor and circuit module technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as low component density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In the drawings, the same reference numerals represent the same or functionally same components.

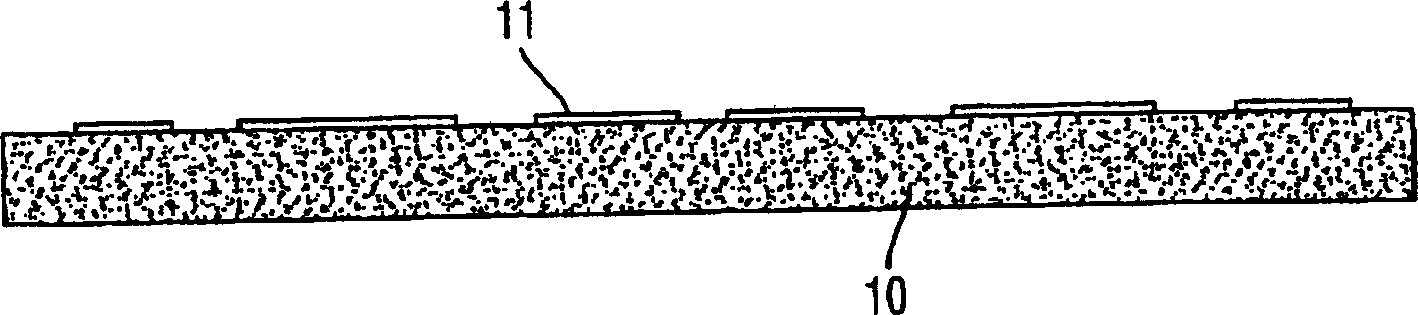

[0049] Figure 1A A transfer substrate 10 is shown, for example made of glass, metal, or polymer, to which a patterned dielectric connection plane 11 is applied in a printing process. The dielectric connection plane 11 is not cured at the time it is being talked about at this time, and is still tacky. The dielectric connection plane 11 comprises, for example, polymer, epoxy, adhesive, silicone, or polyimide.

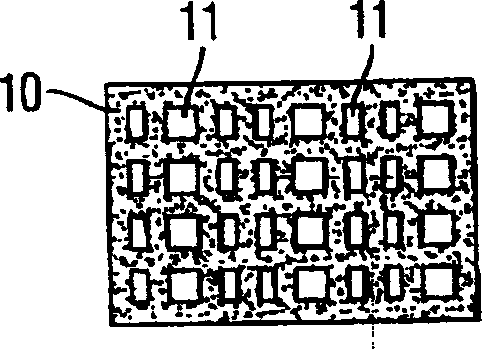

[0050] Figure 1B In plan view a transfer substrate 10 is shown, on which the individual connection regions 11 of a dielectric connection plane 11 are applied, the transfer substrate being made in the form of a rectangle.

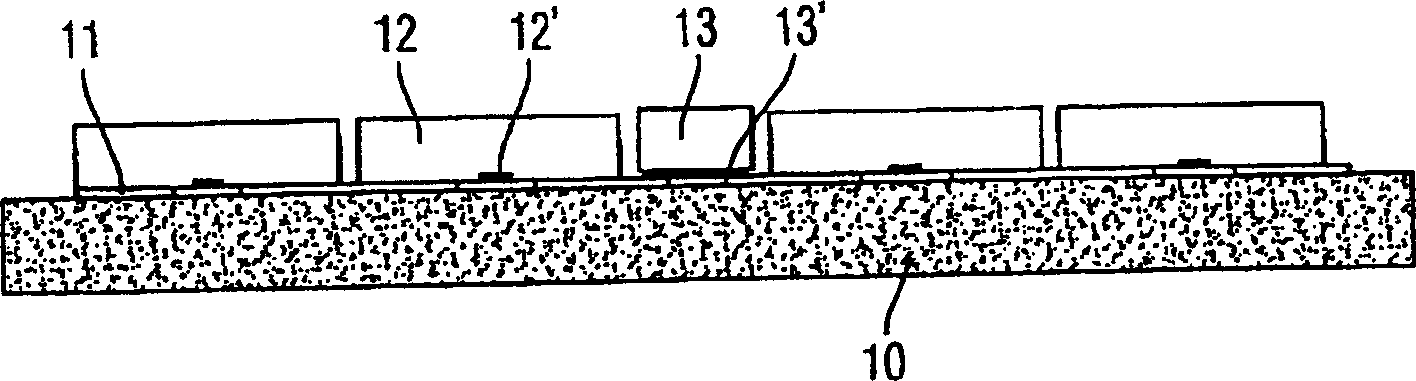

[0051] exist Figure 2A In the embodiment, active circuit devices 12 and passive circuit devices 13 are added to the transfer substrate 10 and the patterned connection plane 11. The circuit devices 12, 13 are added to the predetermined positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com