Flexible multi-joint GaAs solar battery and manufacturing method thereof

A technology of solar cells and solar cells, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing the conversion efficiency of solar cells and affecting the light absorption of solar cells, and achieves the effect of not being easily broken and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

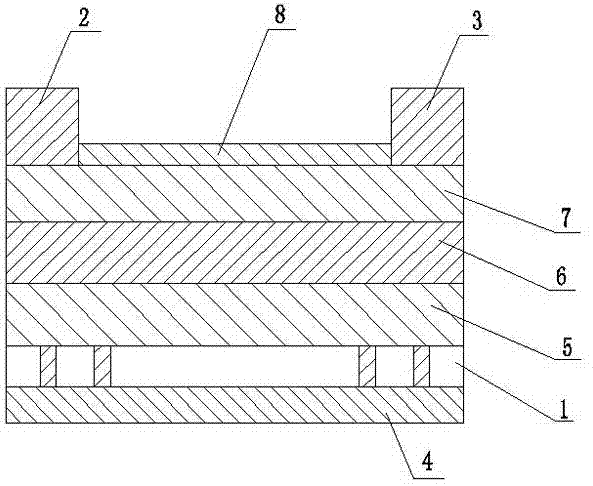

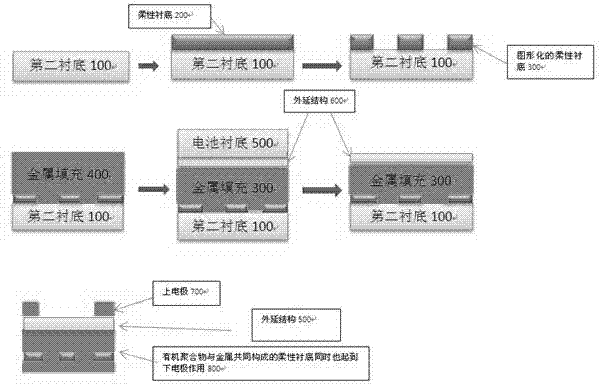

[0042] Specific production methods, such as figure 2 Shown:

[0043] 1. Firstly, on the second substrate 100 (the material that can be used as the second substrate: N-type GaAs), use spin coating technology to coat a layer of organic polymer-polyimide with a thickness of 50-120 μm as Flexible substrate 200.

[0044] During spin coating, a unique spin coating method is used to first coat the low-viscosity polyimide (1800-2000cp) on the substrate by rotating at a high speed of 5000 rpm to form a uniform layer. Better basement membrane. Then reduce the rotation speed to 1000 rpm, and coat the high-viscosity polyimide (5000-6000cp) on the substrate with the base film while the substrate is rotating. A polyimide layer having a thickness of 50 to 120 μm is formed.

[0045] 2. After spin-coating, use photoresist mask technology to coat a layer of photoresist on the polyimide, and choose a low speed to uniform the coating, because the high speed will cause the previously coated p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com