Laser tin welding method and device for rectifier diode assembly parts

A technology of rectifier diodes and assembly parts, applied in the field of laser applications, can solve problems such as circuit debugging, use and maintenance hidden dangers, abnormal circuit operation, low melting point of solder, etc., to avoid mechanical extrusion, energy concentration, and accurate solder joints. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

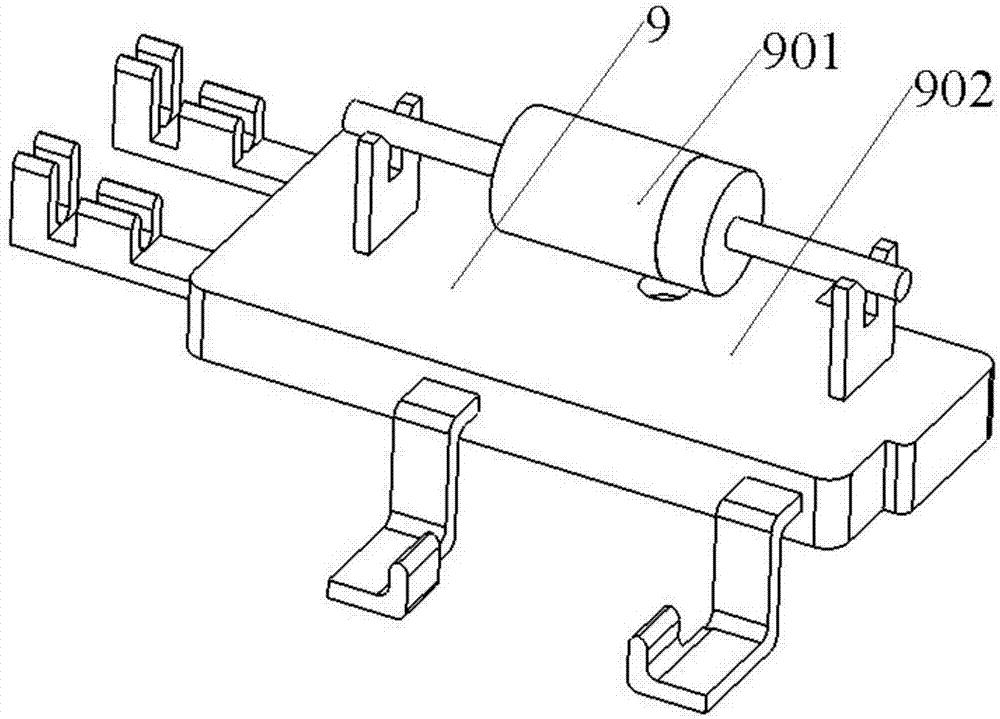

[0056] Such as figure 1 As shown, the rectifier diode assembly 9 is mainly composed of a rectifier diode 901 and a matching base 902, wherein the rectifier diode 901 is composed of lead wires on both sides (referred to as lead wires), chips, solder pieces, plastic packaging materials, etc., and its function is mainly by built-in The PN junction of the semiconductor silicon chip (grain) can conduct forward conduction and reverse cut-off characteristics for the current to achieve the purpose of rectifying the power supply; when in use, the rectifier diode 901 and the matching base 902 need to be welded together to form a rectifier diode Assemblies; the supporting base 902 is relatively independent from the rectifier diode 901, and its upper end surface is provided with two pins to weld and fix the rectifier diode 901 by soldering method, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com