Guide rail device for laser cutting machine

A technology of laser cutting machine and guide rail device, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of increasing the processing width, the guide rail is easy to deform downward, affecting the processing accuracy, etc., to prevent warping and deformation. , Improve the effect of laser processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

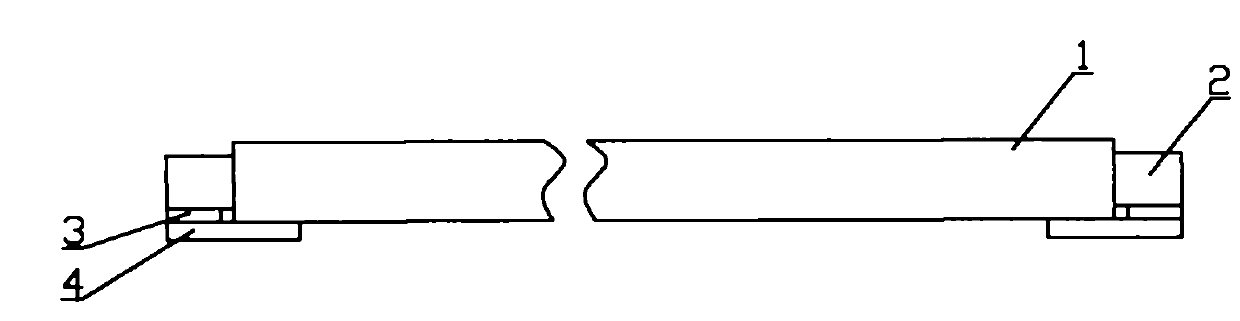

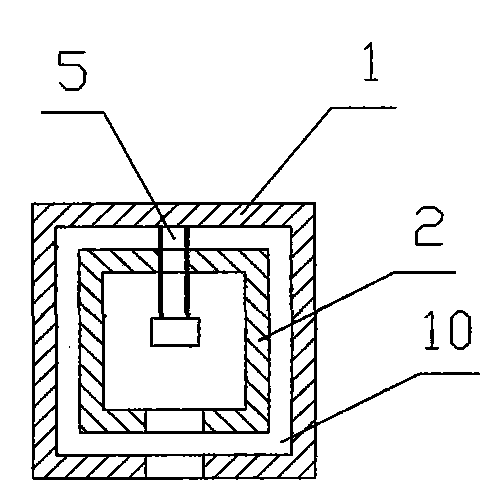

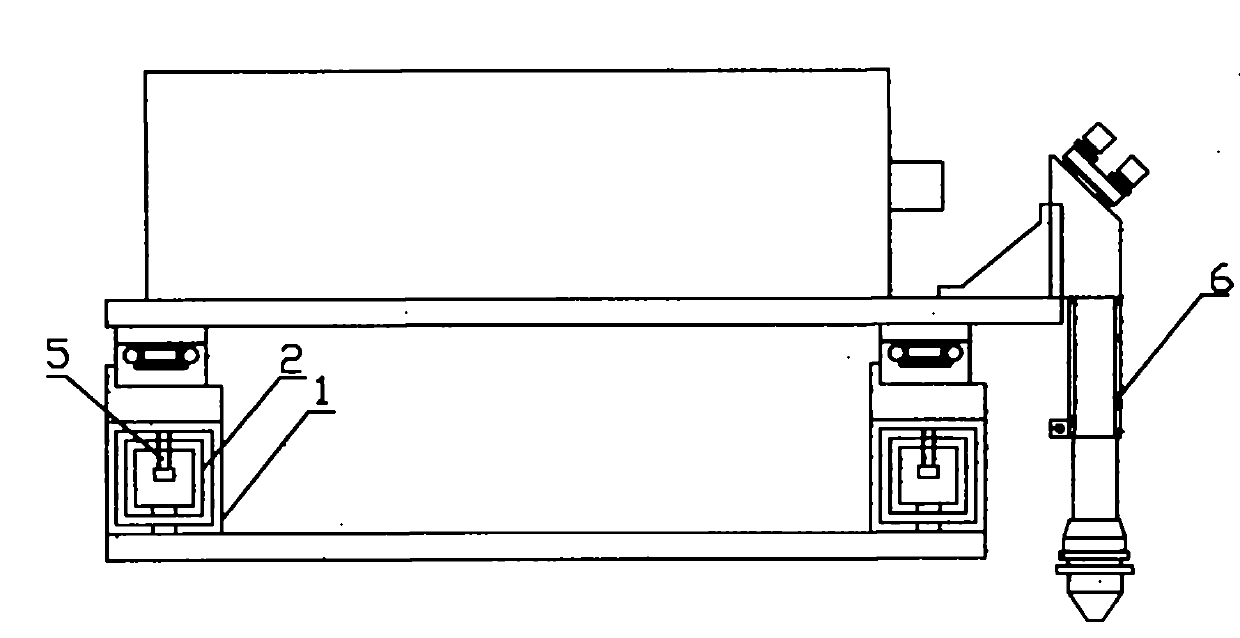

[0022] Please refer to figure 1 and figure 2 , The invention relates to a guide rail device for a laser cutting machine. It includes an X-axis guide rail 1 which is hollow and has openings 10 at both ends. The supporting guide rail 2 passes through the openings 10 at both ends of the X-axis guide rail 1 and runs through the X-axis guide rail 1 . At the same time, there is a certain distance between the bottom surface of the support beam 2 and the bottom surface of the inner wall of the X-axis guide rail 1 . Both the X-axis guide rail 1 and the supporting guide rail 2 are supported on the supporting parts located at both ends of the X-axis guide rail 1 . The support beam 2 is supported on the first support part 3, and the X-axis guide rail 1 is supported on the second support part 4. The first support part 3 is higher than the second support part 4, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com