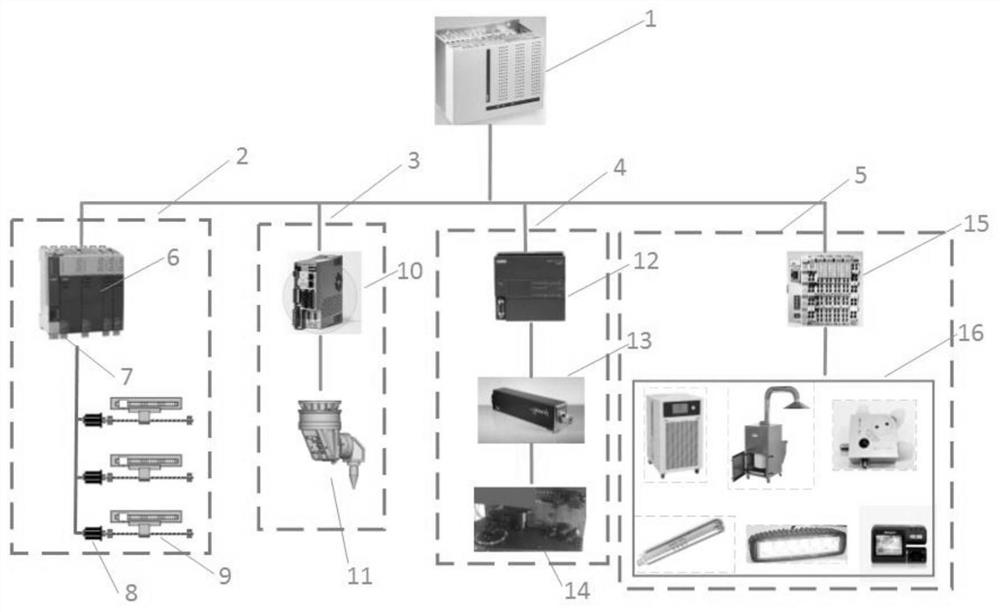

A multi-axis linkage laser processing numerical control system based on industrial computer and its working method

A technology of laser processing and numerical control system, which is applied in general control system, control/adjustment system, laser welding equipment, etc., can solve the problems of poor versatility and poor scalability, and achieve large output torque, good openness, and laser processing accuracy Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

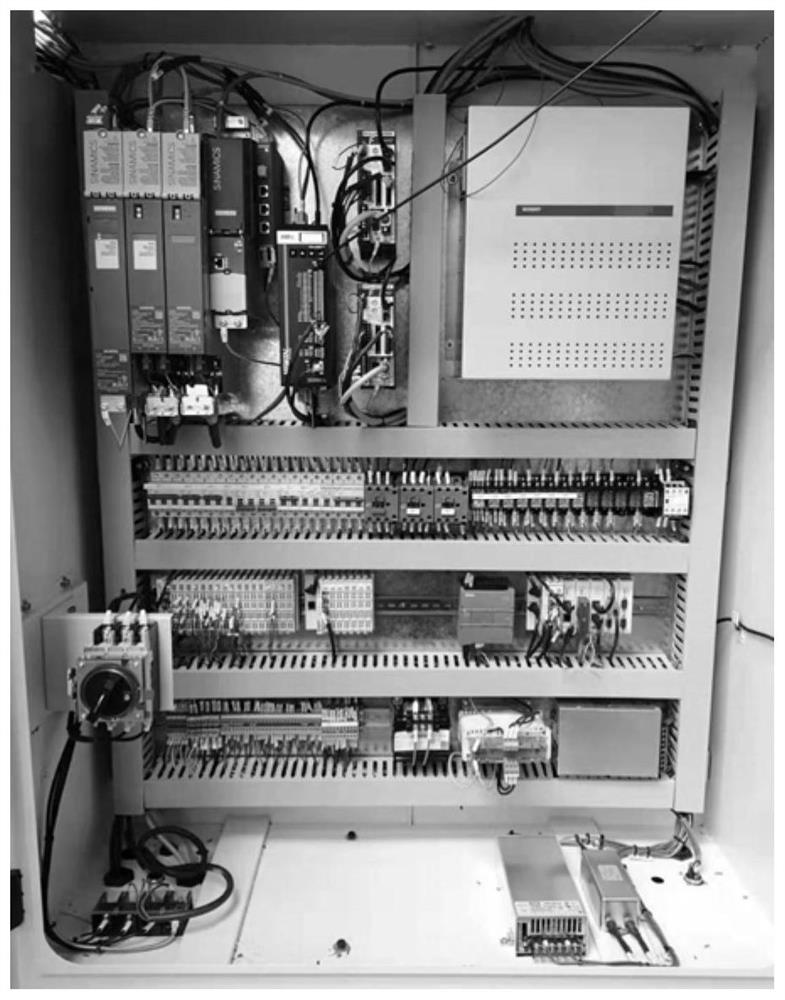

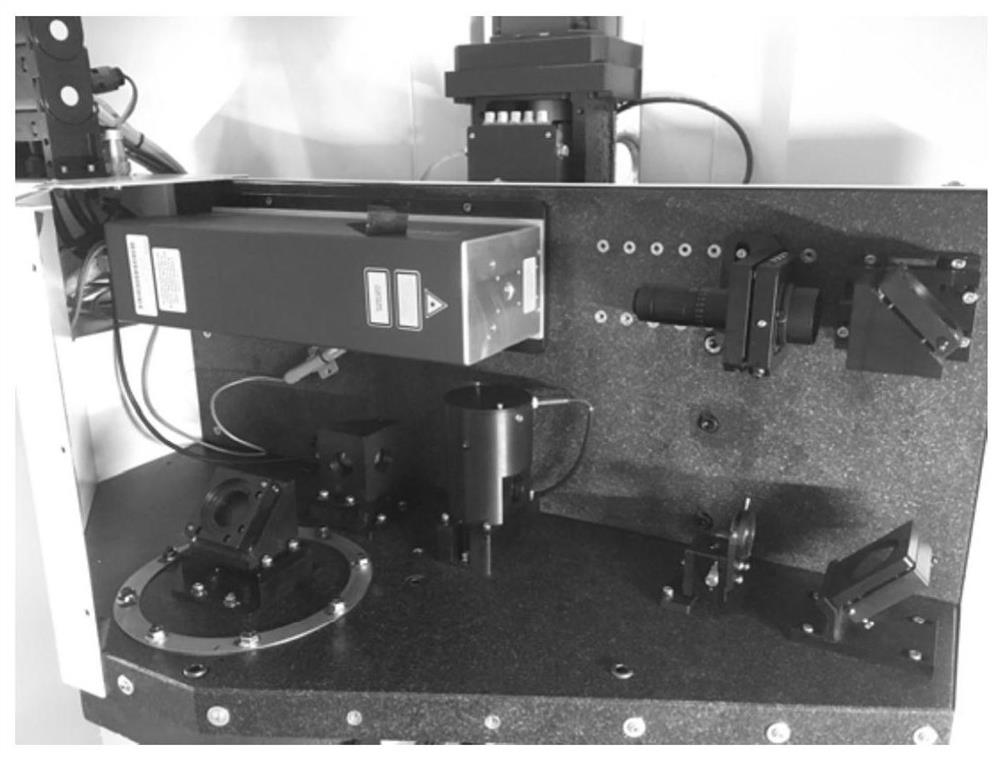

[0045] Embodiment 1: The present invention is specifically described by taking a five-axis linkage laser processing machine tool as an example.

[0046] Such as figure 2 Shown is the physical picture of the electrical cabinet of the five-axis linkage laser processing machine tool. The industrial computer adopts Beckhoff C6640-0040 industrial computer, equipped with CoreTM i7 2.3GHz CPU, with 8G running memory, and the system uses win7 professional version; the functions of the industrial computer are as follows:

[0047] 1: Read in the processing program, and complete the routine processes such as decoding, speed planning, interpolation, coordinate transformation, pitch compensation, etc., and obtain instructions for the cooperative control subsystem;

[0048] Two: Transmit the interpreted motion command to the linear axis control subsystem and the rotary axis control subsystem to realize the position control of the machine tool;

[0049] Three: Transmit the interpreted lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com