Method for mounting main pipeline and main loop of pressurized water reactor nuclear power station steam generator

A technology for pressurized water reactor nuclear power plants and steam generators, applied in the field of equipment-pipelines, can solve the problems that welds cannot be combined and welded at the same time, the difficulty of manufacturing tolerances, and the large amount of construction work, etc., to achieve good installation and welding operating conditions, improve Welding quality, effect of reducing installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is further described below in conjunction with accompanying drawing:

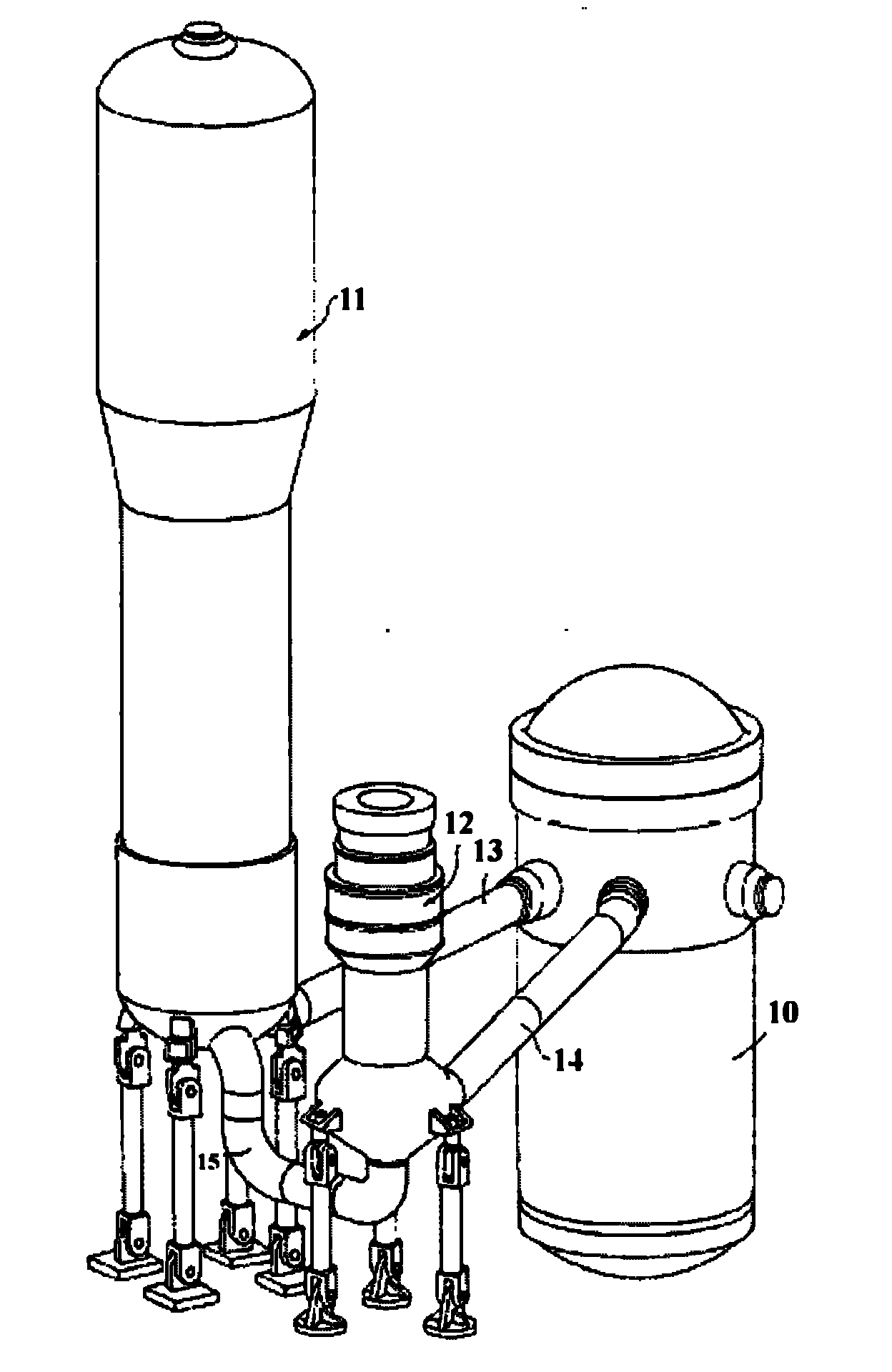

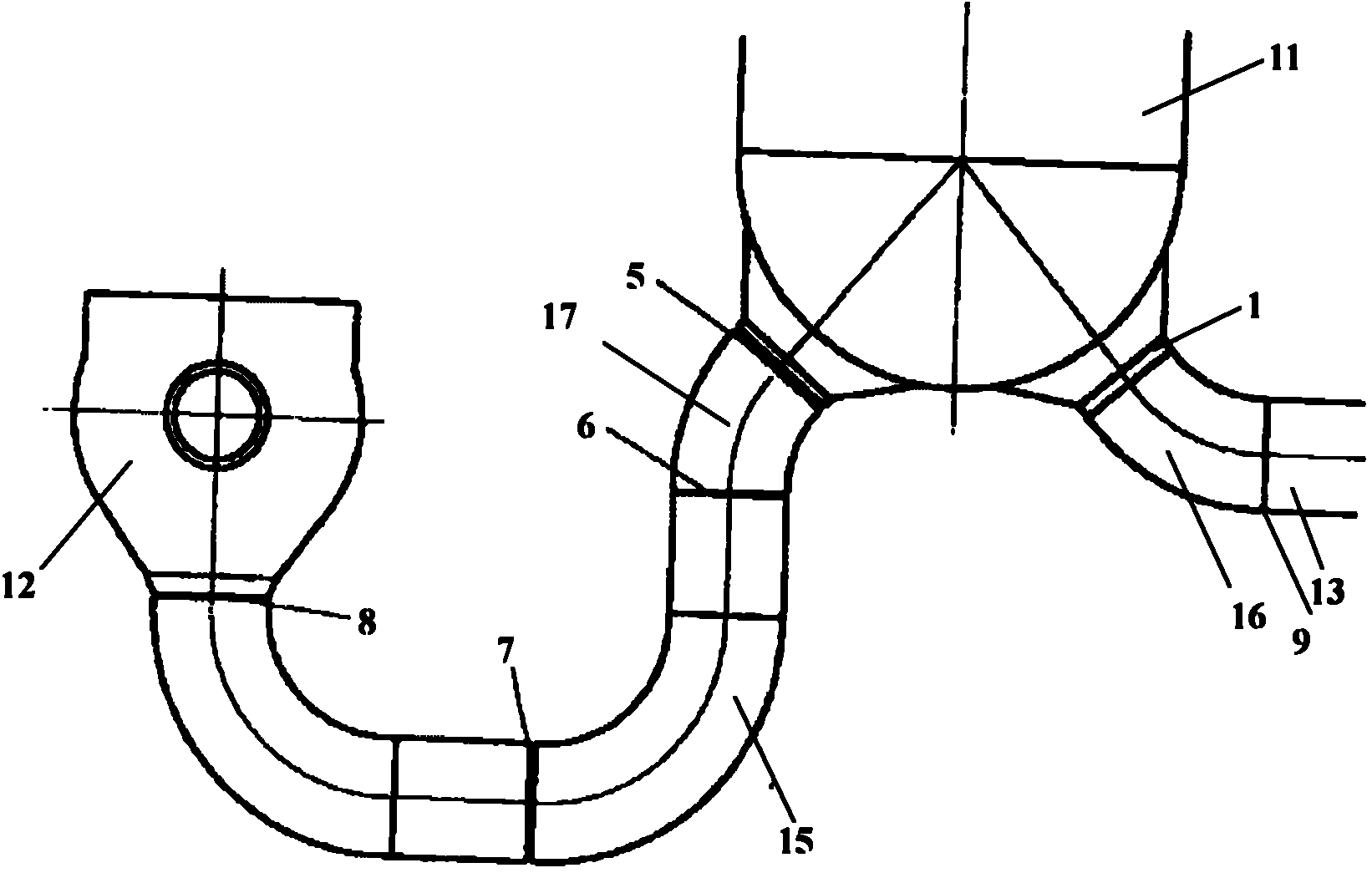

[0038] Such as Figure 5 As shown, the steam generator 11 of the reactor coolant system of the pressurized water reactor nuclear power plant shipped out of the factory has the main pipe hot section elbow 16 and the main pipe transition section elbow 17 respectively welded at the primary circuit nozzle of the lower head.

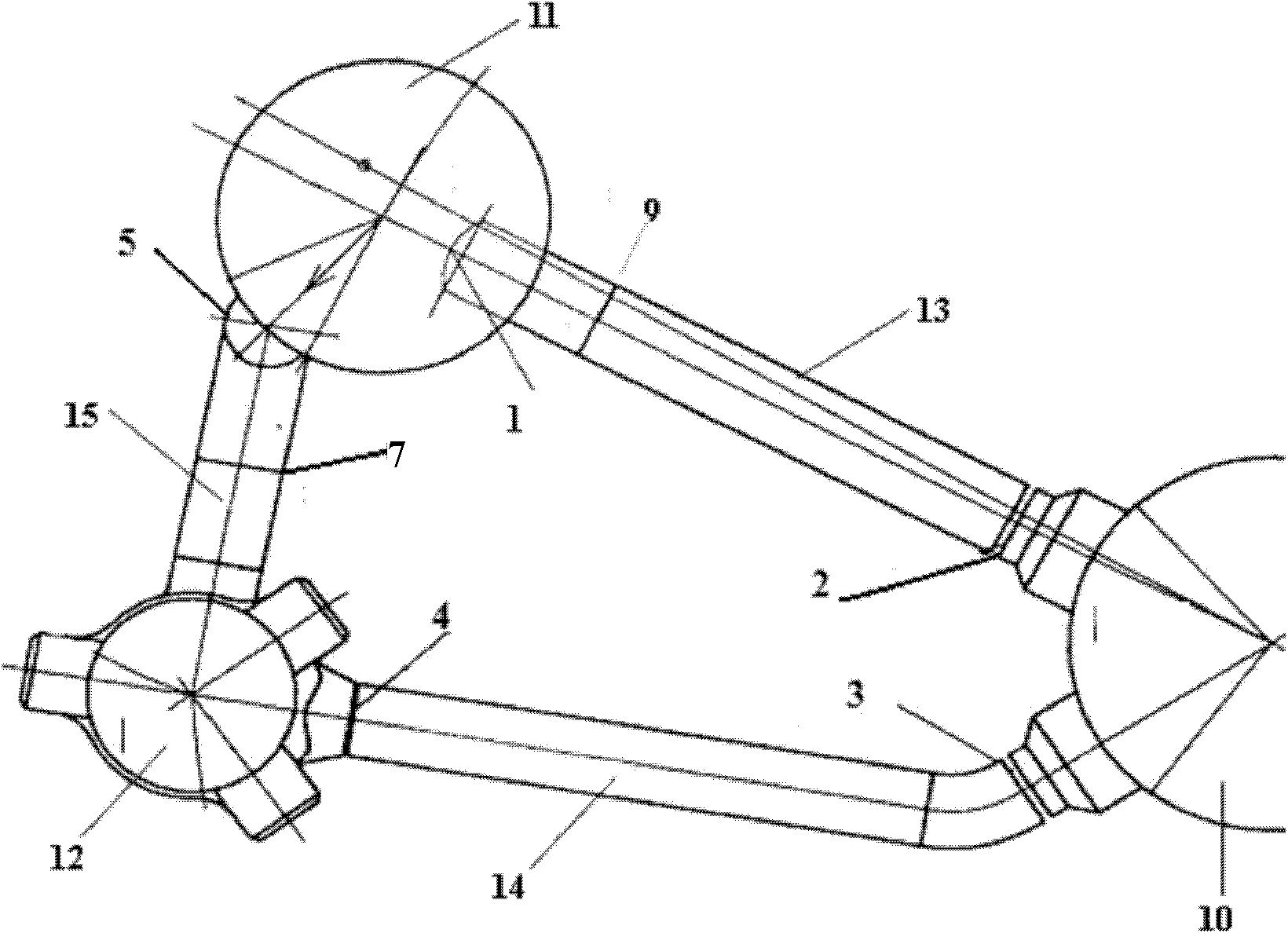

[0039] Such as Figure 8 As shown, the hot section 13 of the main pipeline of the reactor coolant system of the pressurized water reactor nuclear power plant is a straight pipe, excluding the elbow 16 of the original hot section of the main pipeline. Such as Figure 9 As shown, the main pipeline transition section 15 of the reactor coolant system of the PWR nuclear power plant is composed of two sections of pipelines, excluding the original main pipeline transition section elbow 16 .

[0040] Such as figure 1 , figure 2 , image 3 As shown, use Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com