Material and process of manufacture of steel components for screw gun clutches

a technology of steel components and clutches, which is applied in the direction of manufacturing tools, couplings, slip couplings, etc., can solve the problems of reducing the fatigue life of each part, requiring users to spend considerable time and money repairing the clutch or replacing the entire tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

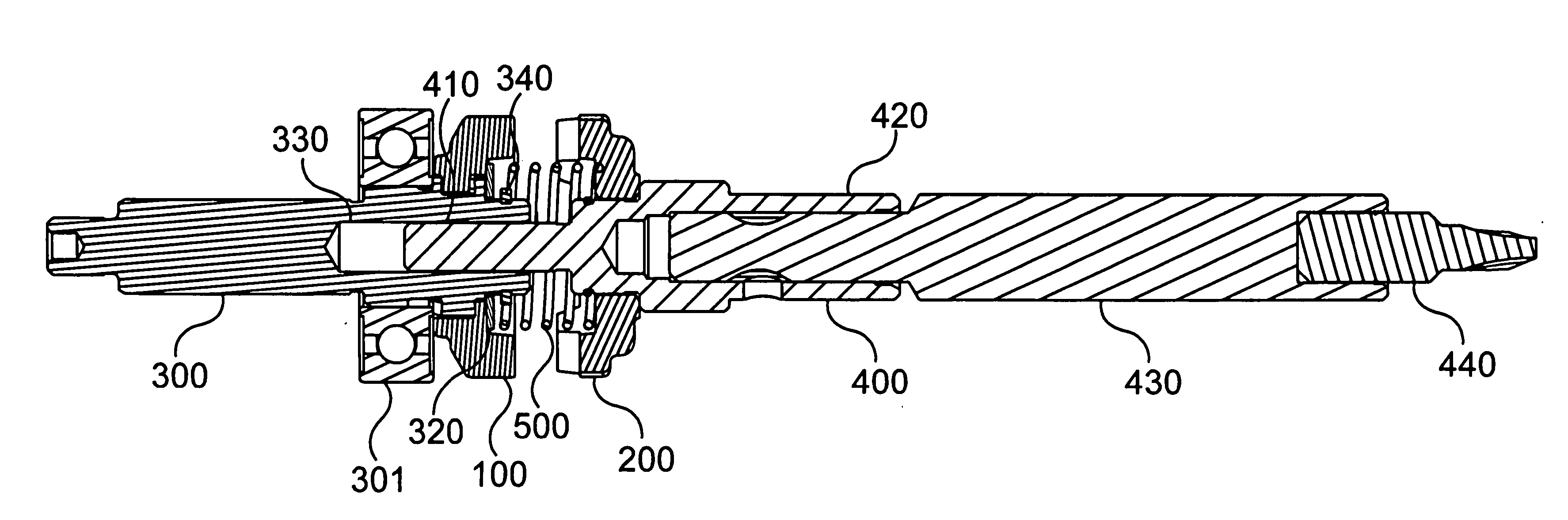

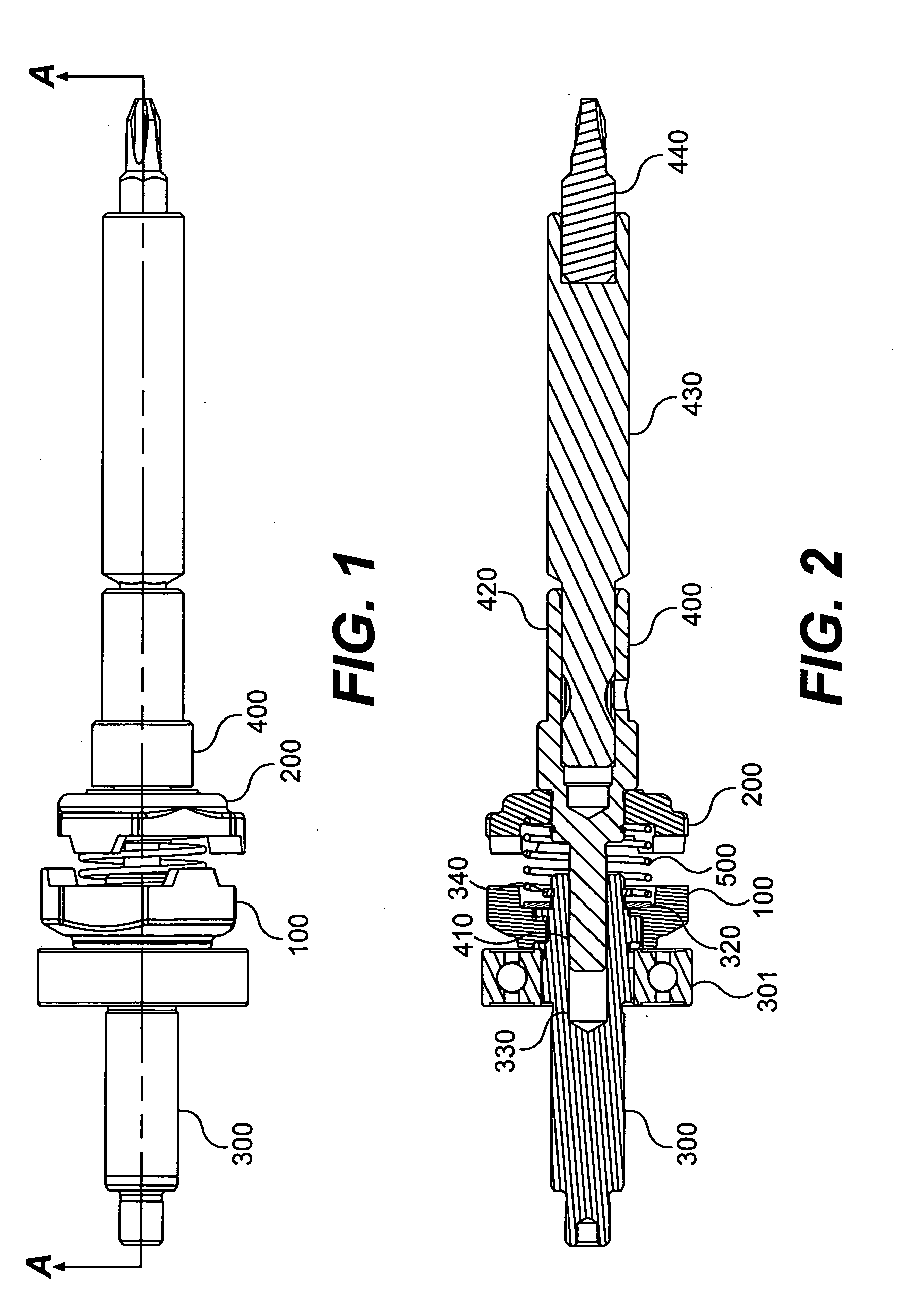

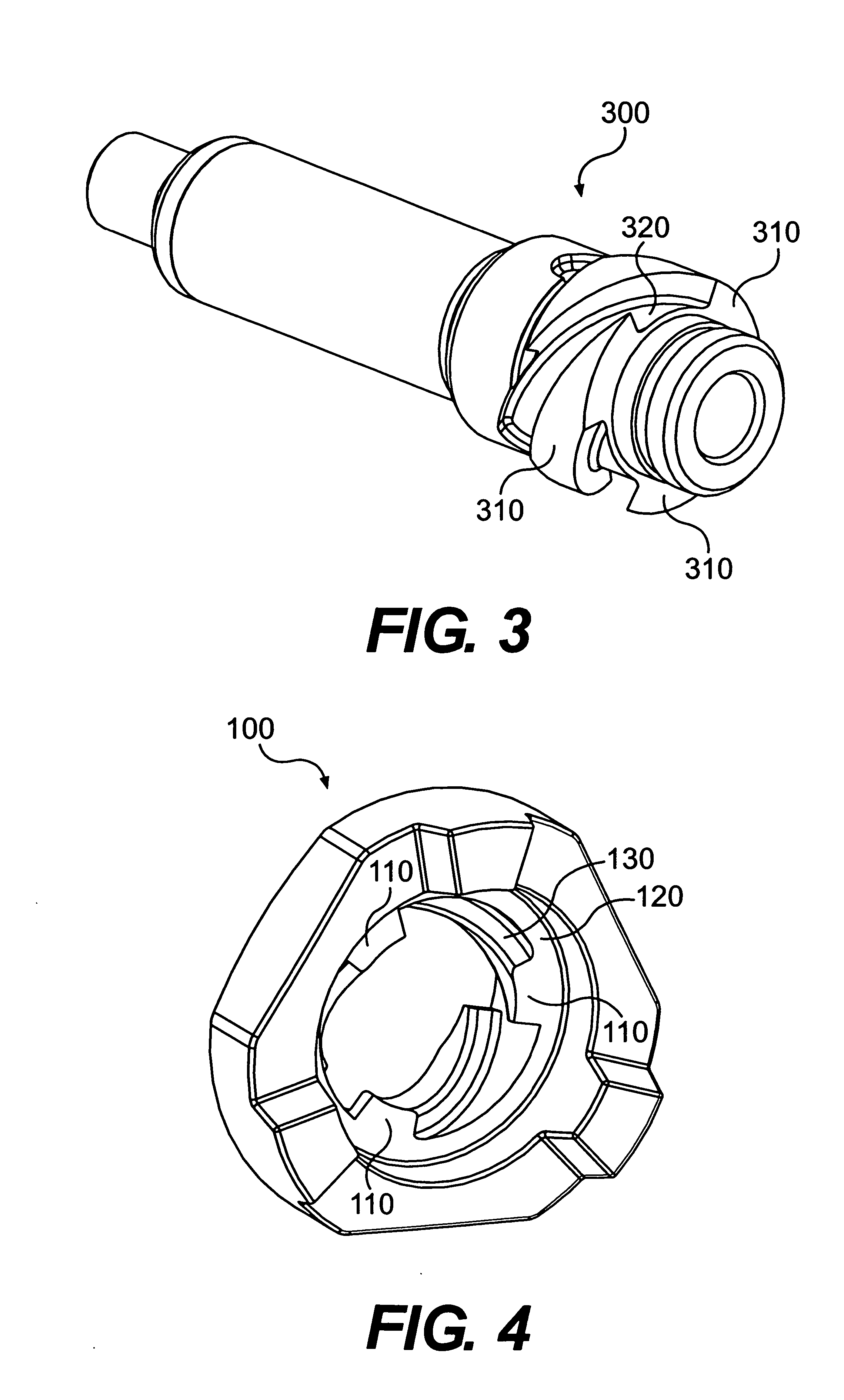

Image

Examples

examples

[0037] Tests were conducted to compare screw gun clutches made from a steel with relatively large amounts of chromium and nickel to screw gun clutches marketed by a competitor. Each of the screw guns in this test operated at a speed of approximately 5,000 r.p.m. and was used to drive 1⅝ inch long screws into a test material. The competitor's screw gun utilized a clutch with lugs similar to those depicted on clutches 100 and 200 herein. The clutches in the competitor's screw gun are made from SAE 8620 steel. The competitor's screw gun drove approximately 6,000 screws when it was judged to be operating roughly because the clutch was chattering.

[0038] A screw gun built by the assignee of this invention was also used at approximately 5,000 r.p.m. to drive 1⅝ inch long screws into the test material. This screw gun utilized a clutch with the helical spline design depicted in the drawings herein and which was made from a steel with relatively large amounts of chromium and nickel—in this c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| helix angle | aaaaa | aaaaa |

| helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com