Damage-resistant shower base and installation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

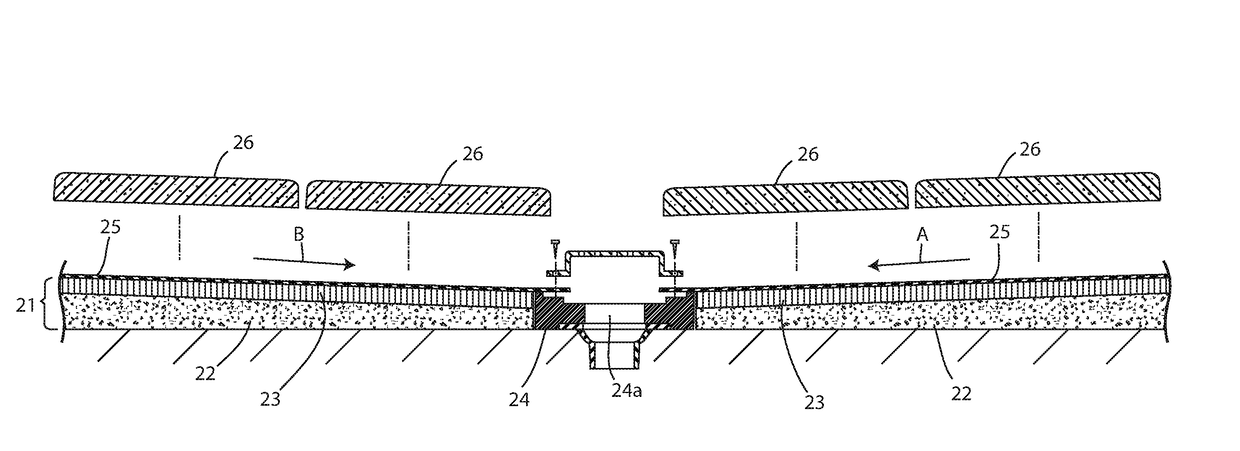

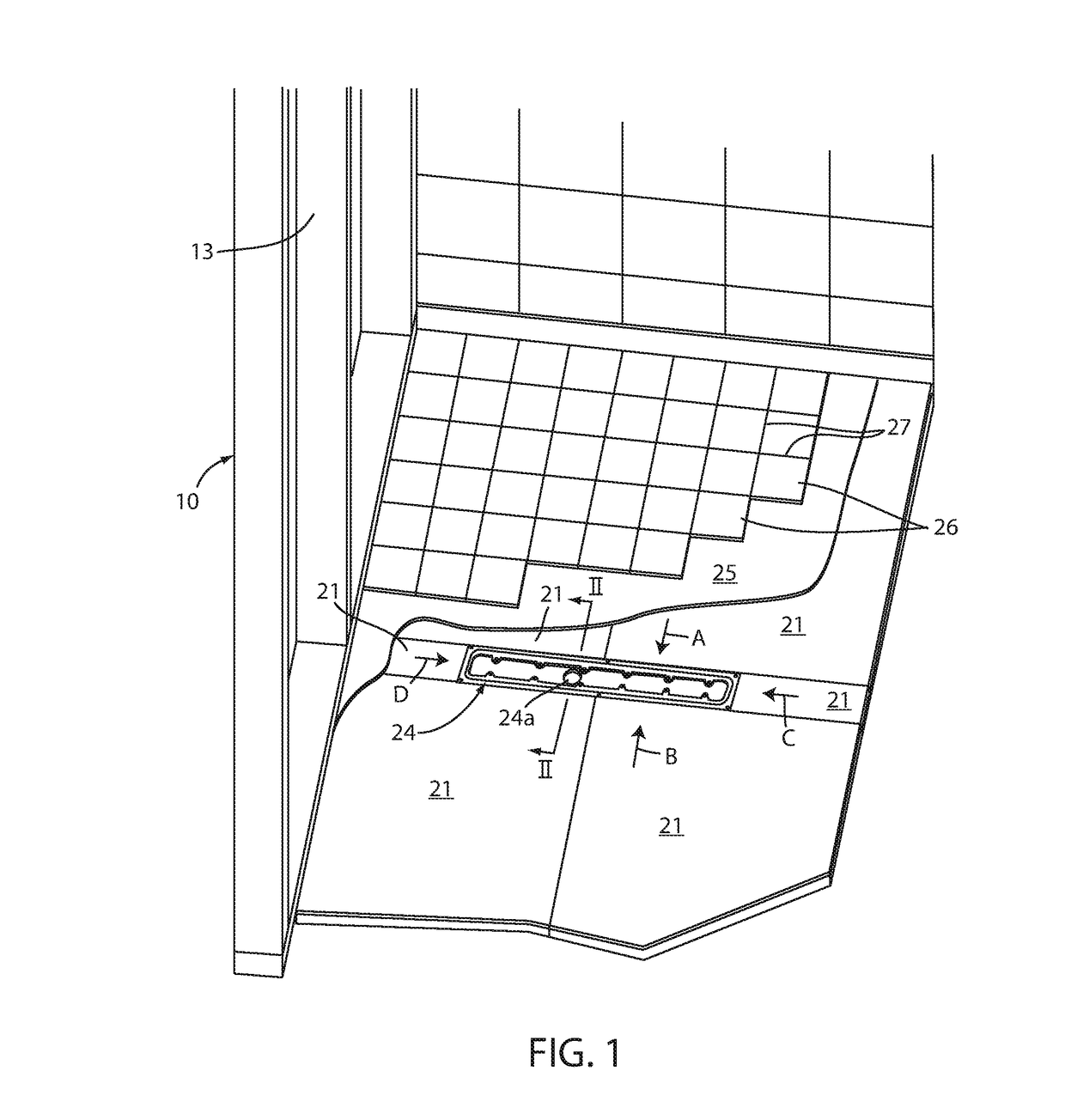

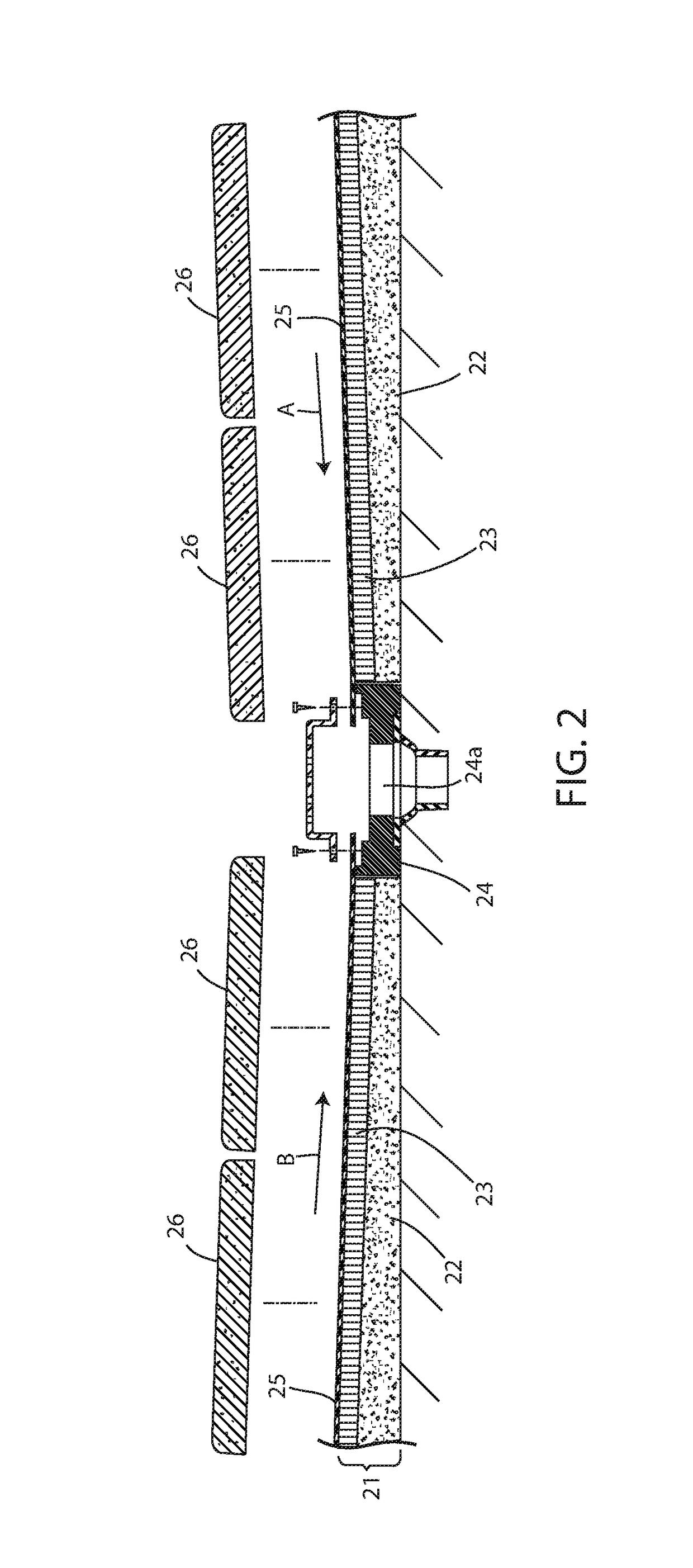

[0032]FIG. 1 is a perspective view of a partially-installed shower base apparatus in a shower structure 10 of a building. The shower structure 10 includes a floor surface, a first building wall (illustrated with drywall covering attached), and a second wall 13 (defined by the illustrated studs). The shower base apparatus is shown as partially installed in the shower structure 10. The shower base apparatus in FIG. 2 includes a combination slab 21, the combination slab 21 including at least one tapered or flat foam slab 22 (preferably polystyrene foam) with a sloped upper surface; and a deformation-resisting thin slab 23 (preferably a honeycomb slab of about 0.250-0.300 inch thickness) bonded to the sloped upper surface 22A of the foam slab 22 to form a deformation-resisting layer on the foam slab 22. The shower base apparatus 20 also includes a drain 24 (illustrated as a trench drain 24) with drain opening 24a, a waterproofing membrane 25, and tile 26 bonded using thinset to the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com