Silicon rubber wrapped rubber tube using carbon fiber as reinforcing layer and manufacture process thereof

A technology of carbon fiber cloth and manufacturing process, which is applied in the field of silicone rubber cloth hose, can solve the problems of low temperature resistance and low pressure resistance of skeleton materials, and achieve the effect of improving horsepower and power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

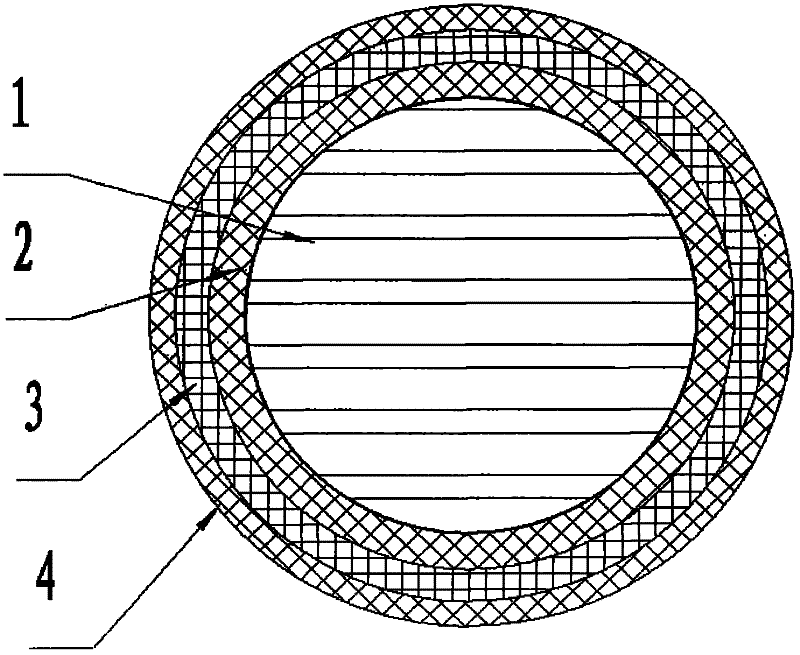

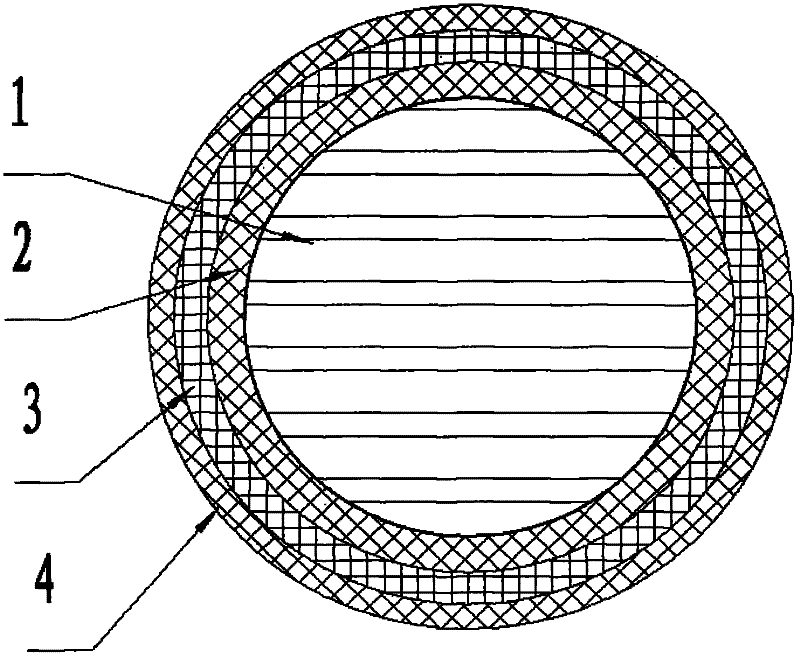

[0020] Attached below figure 1 The silicone rubber-coated rubber hose with carbon fiber as the reinforcing layer and its manufacturing process will be described in detail.

[0021] A manufacturing process of a silicone rubber-coated rubber hose with carbon fiber as a reinforcement layer, comprising the following steps: surface-treating carbon fiber cloth 3 to increase the content of polar groups on its surface; winding an inner rubber layer on a mold core 1 of a required size 2. Wrap the surface-treated carbon fiber cloth 3 as a reinforcing layer on the inner rubber layer 2; wrap and wind the outer rubber layer 4 on the surface of the carbon fiber cloth 3 to form a rubber hose; vulcanize the rubber hose to obtain a finished product, wherein the inner rubber Layer and cover consist of silicone rubber. Preferably, according to different requirements, this composite mode can be implemented repeatedly, such as carbon fiber cloth 3→silicon rubber layer 4→carbon fiber cloth 3→silic...

Embodiment 2

[0027] This embodiment provides a preferred technical process for bonding carbon fiber cloth 3 to silicon rubber. The surface of the carbon fiber cloth 3 is treated through a certain process, so that it has good bonding performance and adhesion strength with the silicone rubber. Because the carbon fiber cloth 3 without surface treatment has a small content of carbonyl, carbonyl and other polar groups on the surface, which is not conducive to bonding with the matrix material, its surface is chemically inert, and is not easy to infiltrate or chemically react with the matrix material. Therefore, in order to realize the load transfer between rubber and fiber, give full play to the reinforcing effect of carbon fiber, and improve the mechanical properties and temperature resistance of composite materials, the surface of carbon fiber must be treated. Preferably, the specific treatment process of this embodiment is as follows: firstly, with NH 4 HCO 3 As an electrolyte, pass current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com