Combined power generating system based on waste-heat utilization of combustion motor

A technology of combined power generation and internal combustion engine, applied in the direction of internal combustion piston engine, charging system, combustion engine, etc., can solve the problems of difficulty in application, large heat exchange temperature difference of heat exchanger, large irreversible loss, etc., to improve the utilization efficiency of waste heat. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

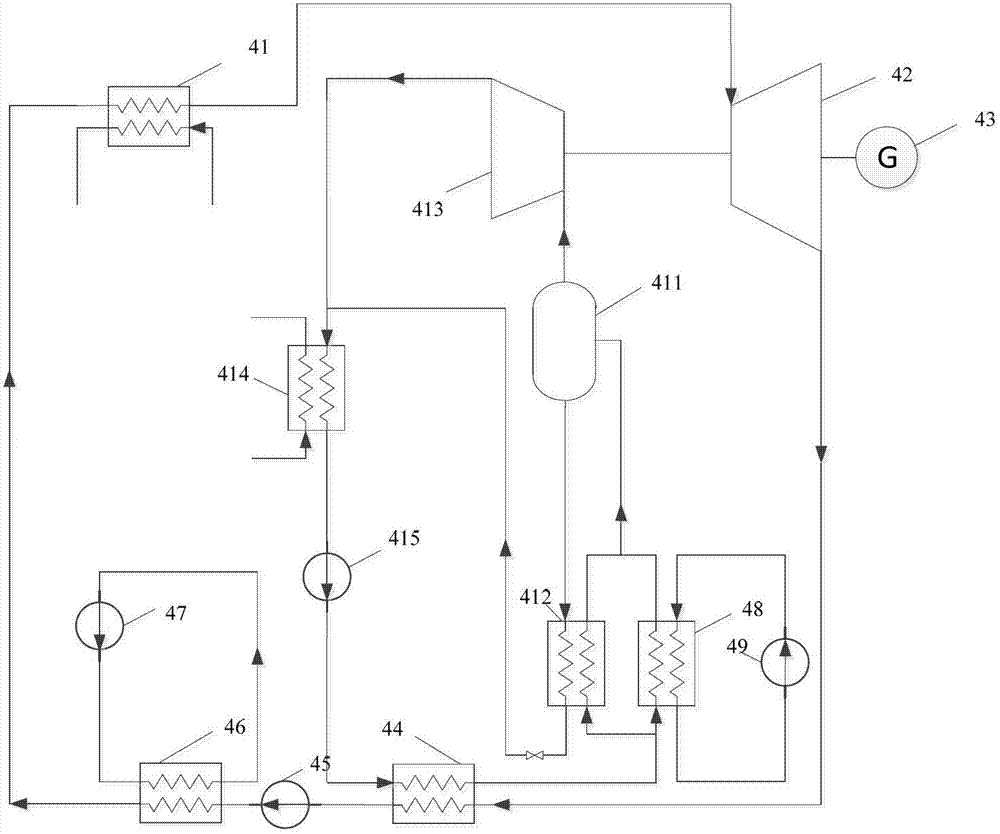

[0032] Figure 5 It is a flow chart of a combined power generation system based on the utilization of waste heat of an internal combustion engine according to the present invention. The system consists of an internal combustion engine 1, a first generator 2, a heater 3, a gas turbine 4, a second generator 5, a cooler 6, a compressor 7, an organic working fluid turbine 8, a third generator 9, a condenser 10. It consists of a booster pump 11, an evaporator 12, and a preheater 13. The system is composed of Brayton cycle and organic Rankine cycle. Brayton cycle is selected as the top cycle and CO 2 As the working fluid, the organic Rankine cycle is used as the bottom cycle, and R123, R113, R245fa, isopentane, etc. can be selected as working fluids. The combined cycle power generation system is used to realize the cascade recovery and utilization of the waste heat of the internal combustion engine. In addition, the internal combustion engine uses LNG as fuel. In order to utilize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com