Valves for gas-turbines and multipressure gas-turbines, and gas-turbines therewith

a gas turbine and multi-pressure technology, applied in the field of gas turbines, can solve the problems of not being able to meet sudden increase power demand, less efficient at part load, and not well known gas turbine applications in the field of work-producing motors, and achieve the effect of reducing the oxygen content of the combustible mixture and reducing the amount of nox produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

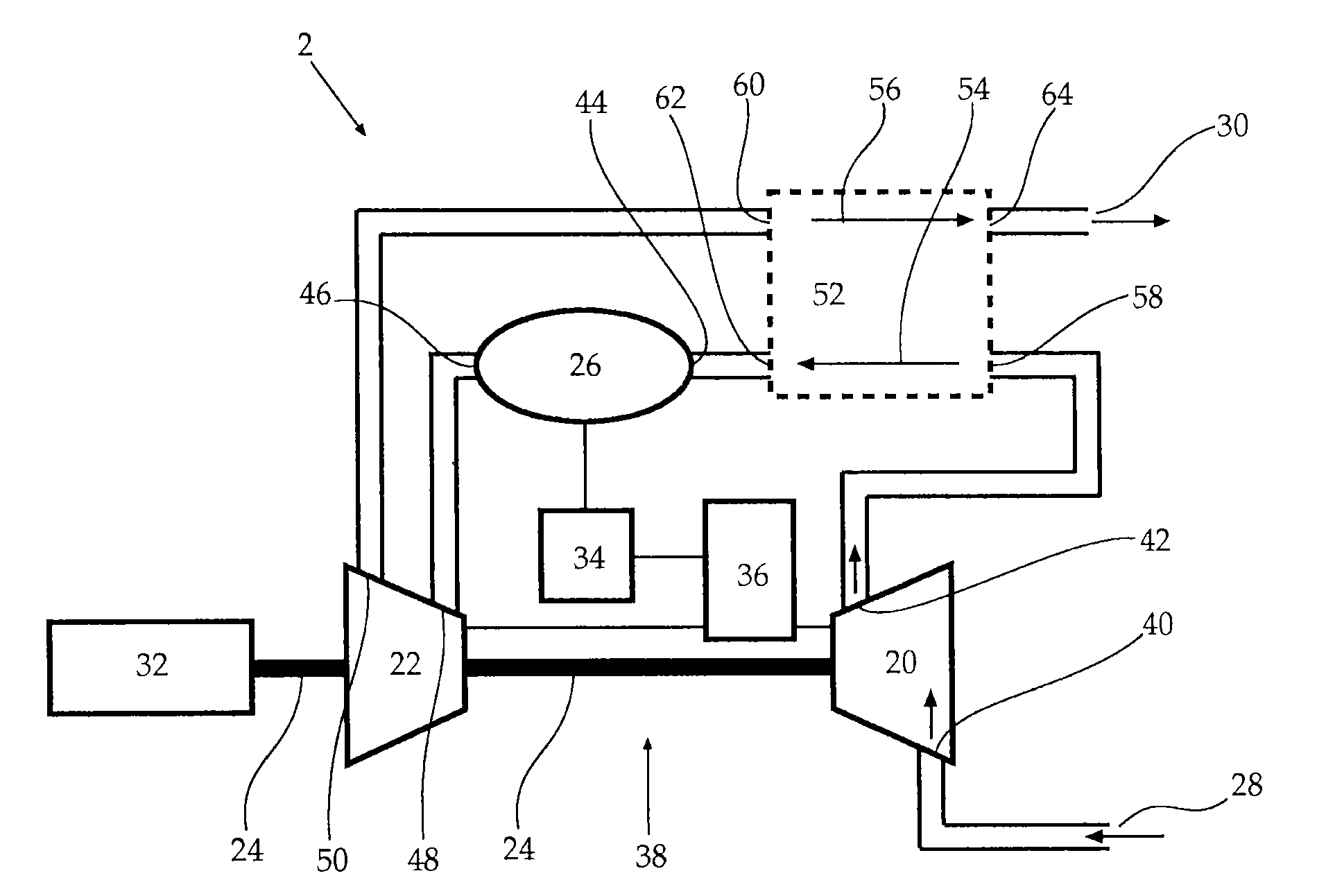

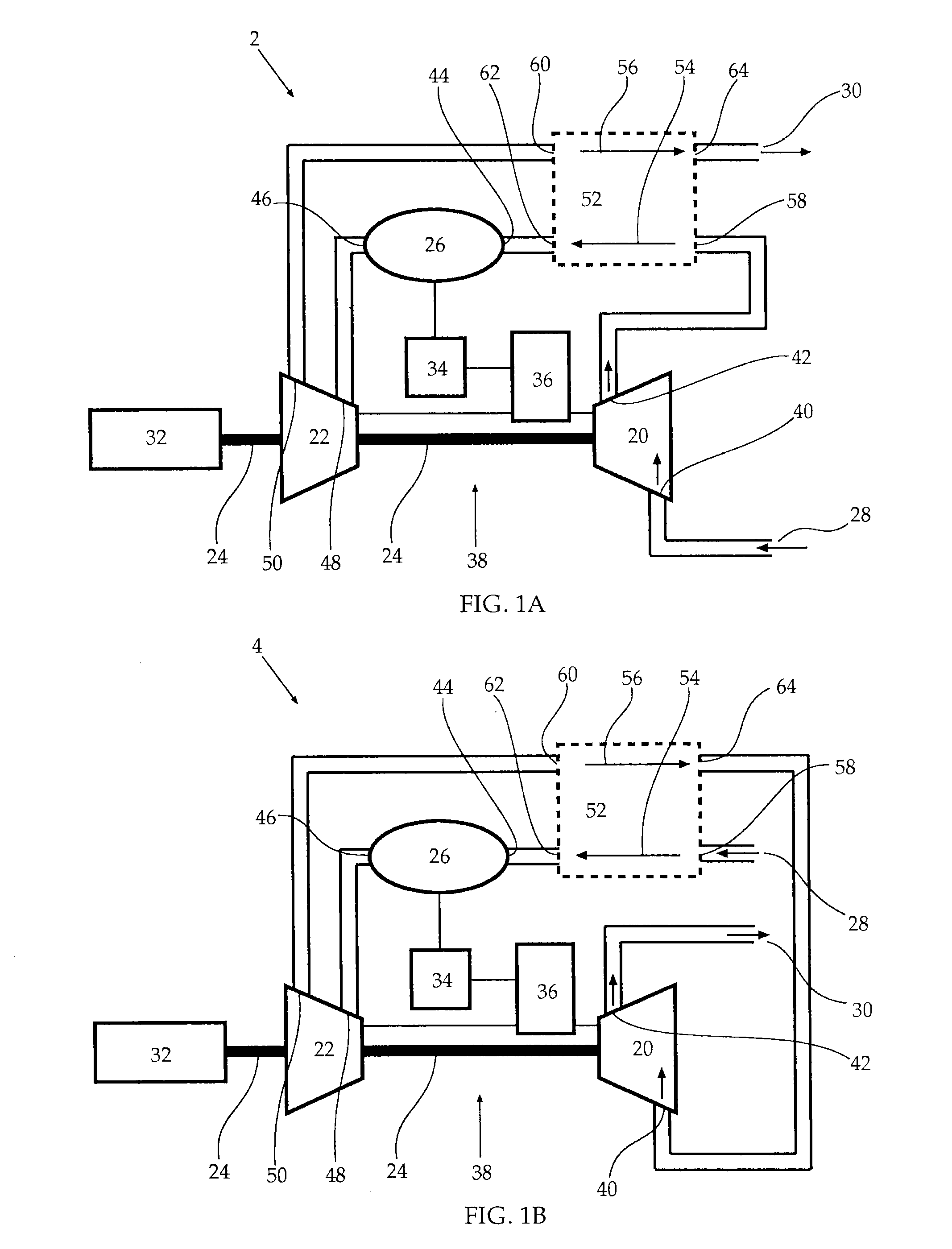

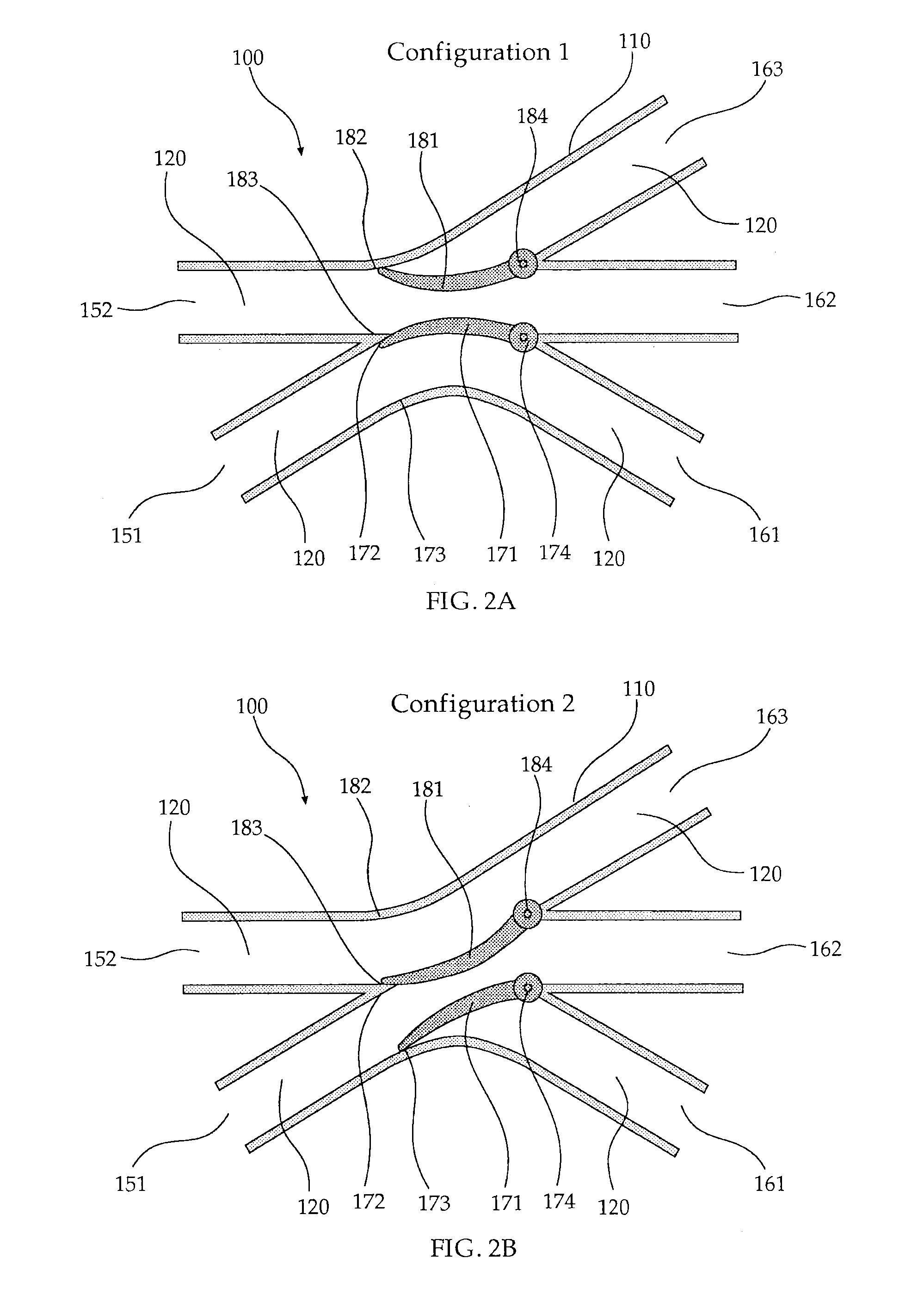

[0068]Some embodiments of the invention relate to multiport valves that allow switching between high-pressure operation (Brayton cycle) and low-pressure operation (inverse Brayton cycle) modes of a gas-turbine.

[0069]Some embodiments of the invention relate to multiport valves that allow operation of a gas-turbine in high-pressure, low-pressure and intermediate pressure modes.

[0070]Some embodiments of the invention relate to multiport valves that allow operation of a gas-turbine at a variable power output in high-pressure modes and / or low-pressure modes at relatively high efficiency by varying the mass flow through the gas-turbine. Some embodiments of the invention relate to valves that allow simple and efficient varying of the pressure, mass flow and power output of a gas-turbine, that in some embodiments is substantially continuous.

[0071]Some embodiments of the invention relate to gas-turbines operating in a low-pressure mode (inverse Brayton mode) having reduced NOx emissions as w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com