Continuous casting secondary cooling dynamic control method based on online temperature measuring and heat transferring model

A heat transfer model and dynamic control technology, which is applied in the field of continuous casting secondary cooling dynamic control, can solve problems such as the improvement of control affecting the quality of continuous casting slabs, and achieve the effect of improving the accuracy of temperature prediction and improving the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

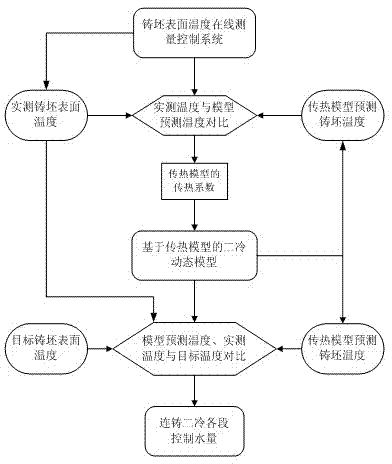

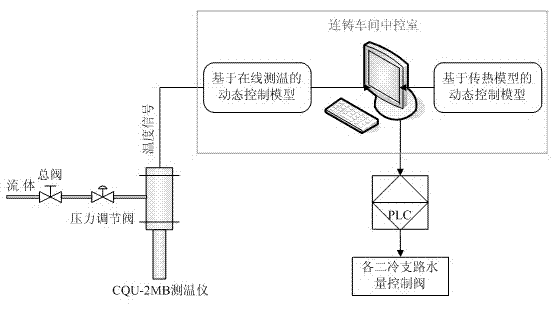

[0063] see figure 1 and figure 2 , a dynamic control method for continuous casting secondary cooling based on online temperature measurement and heat transfer model, combining the dynamic control model of online temperature measurement and the dynamic control model of heat transfer model to construct a new dynamic model of continuous casting secondary cooling and implant it into the computer system. The water distribution system of the continuous casting machine is connected and communicated with the PLC controller; the non-contact temperature measuring instrument CQU-2MB is installed in the continuous casting straightening area, and connected and communicated with the PLC controller to form a new dynamic model of the continuous casting secondary cooling Feedback loop; the specific method includes the following steps:

[0064] 1) The new dynamic model of continuous casting secondary cooling collects the current process operation parameters online, including casting speed, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com