A sulfur-resistant noble metal hydrodesulfurization catalyst

A hydrodesulfurization, precious metal technology, applied in the direction of organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low cracking activity of catalysts and achieve low cracking activity , good sulfur resistance stability, the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

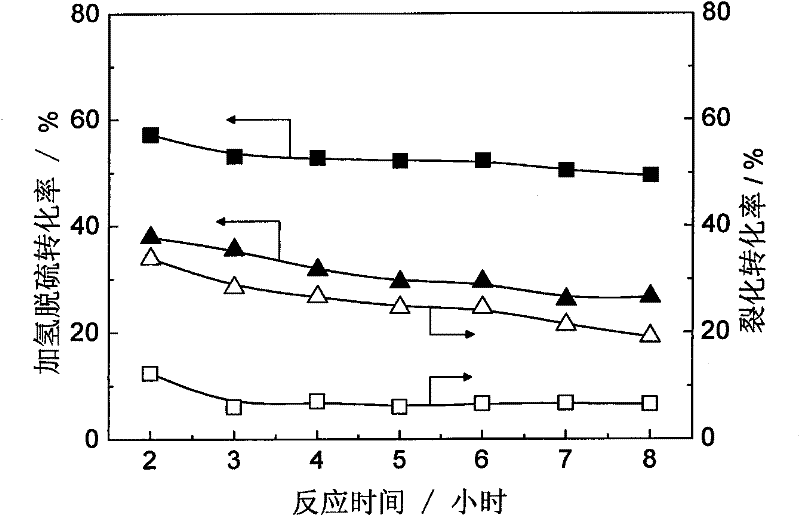

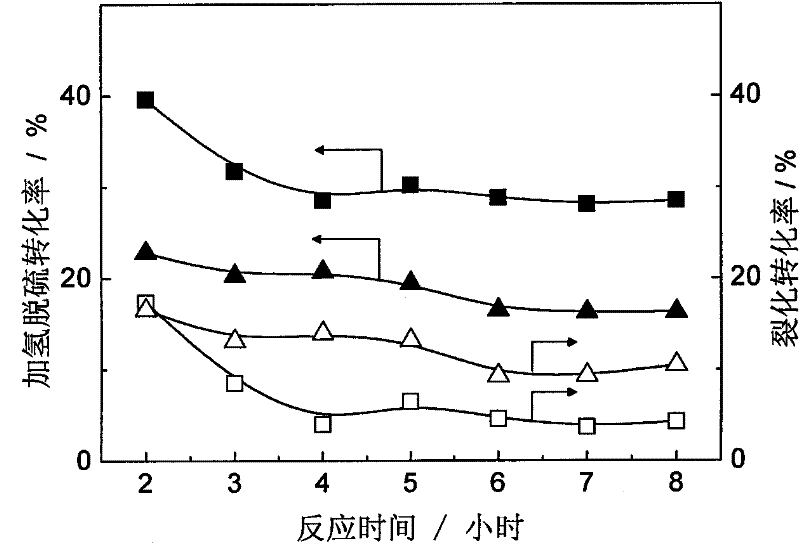

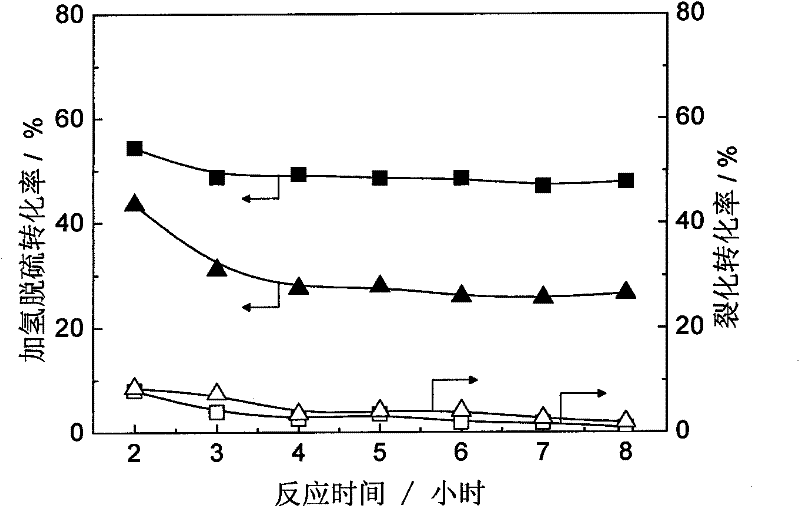

Image

Examples

Embodiment 1

[0015] Preparation of silanized modified all-silicon MCM-41 (Si-MCM-41) supported Pd catalyst precursor by excess impregnation method: first place Si-MCM-41 in toluene (molecular sieve / toluene ratio: 1 g molecular sieve / 50ml toluene), then added trimethylchlorosilane (5% by volume), stirred and refluxed at 100°C for 6h, then filtered with suction, washed with toluene, and dried at room temperature for 12h to obtain silanized modified Si -MCM-41. Dissolve 0.022g of palladium acetate in 20ml of toluene, then add 1g of silanized modified Si-MCM-41, stir thoroughly for 10h, filter with suction, wash with absolute ethanol, dry in an oven at 120°C for 16h, and then The furnace was raised to 400° C. at 1° C. / min, and calcined for 5 hours to obtain a catalyst precursor. The loading amount of Pd was 0.2806 wt%. Record the catalyst as Pd / MCM-41(S)

Embodiment 2

[0017] Preparation of Silanized SiO by Isovolumetric Impregnation 2 Supported Pd catalyst precursor: first SiO 2 placed in toluene (SiO 2 / toluene ratio: 1g SiO 2 / 50ml toluene), then added trimethylchlorosilane (5% by volume), stirred and refluxed at 100°C for 6h, then suction filtered, washed with toluene, and dried at room temperature for 12h to obtain silanized modified SiO 2 . Dissolve 0.022g of palladium acetate in 3.5g of toluene, and fully dissolve by ultrasonic vibration. Weigh 1g of the silanized carrier powder and add it to the impregnation solution, impregnate it at room temperature for 8 hours, then dry it in an oven at 120°C for 16 hours, heat it up to 400°C in a muffle furnace at 1°C / min, and roast it for 5 hours to obtain the catalyst. body, the loading of Pd is 1wt%, and the catalyst is denoted as Pd / SiO 2 (S).

Embodiment 3

[0019] The Pt catalyst precursor supported by all-silicon MCM-41 was prepared by equal volume impregnation method, and then modified by silanization: 0.03g H 2 PtCl 6 Dissolve in 1.5mL of deionized water, then weigh 1g of Si-MCM-41, add to the above impregnation solution, impregnate at room temperature for 8h, dry in an oven at 120°C for 12h, and place in a muffle furnace at 400°C Calcined for 3 hours to obtain the precursor in the oxidized state. Place the precursor in toluene (precursor / toluene ratio: 1g precursor / 50ml toluene), then add trimethylchlorosilane (volume fraction 5V%), stir and reflux at 100°C for 6h, then suction filter, use Wash with water and ethanol, and dry at room temperature for 12 hours to obtain a catalyst precursor. The loading amount of Pt is 1wt%, and the catalyst is recorded as Pt / MCM-41(S)

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com