Thick oil demulsifying agent and preparation method thereof

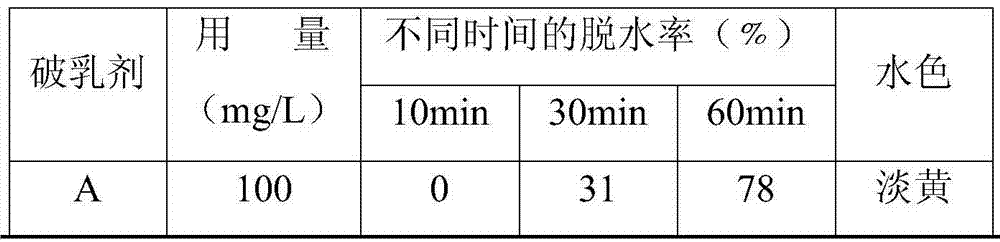

A technology of demulsifier and heavy oil, which is applied in the field of heavy oil demulsifier and its preparation, which can solve the problems affecting the exploitation and transportation of heavy oil, long dehydration time and high dehydration temperature, and achieve fast dehydration, high dehydration rate and easy diffusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

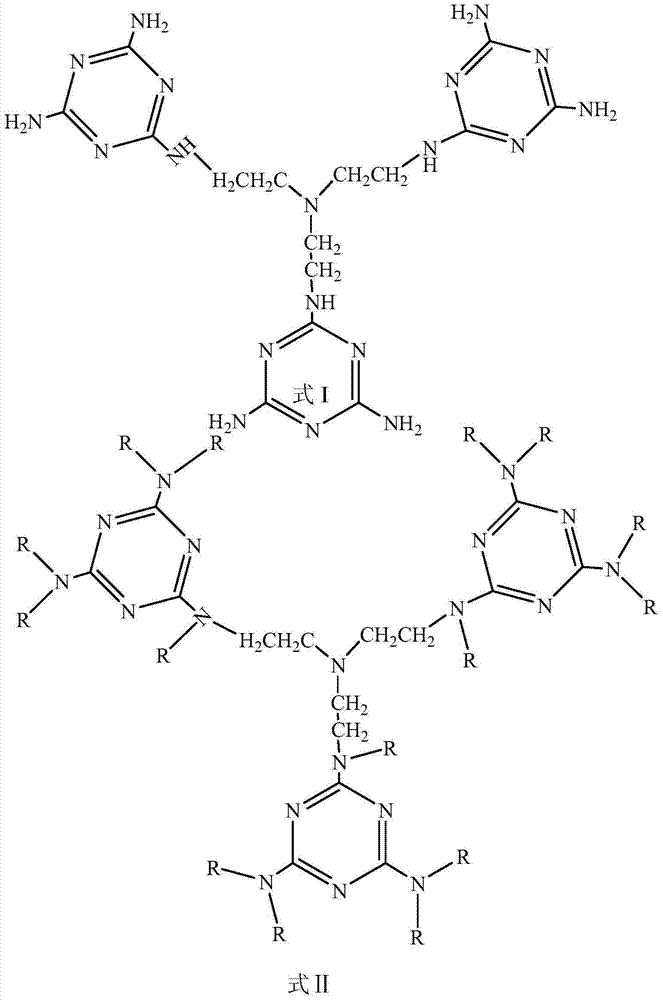

[0035] Embodiment 1, the synthesis of demulsifier A

[0036] (1) Synthesis of polyether

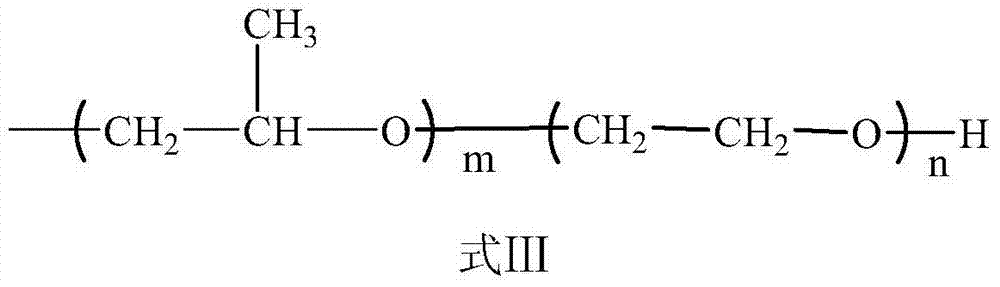

[0037] Add 10 g of the above initiator and 5 g of KOH into the autoclave; seal the reactor system, and replace the air in the autoclave, feed tank and feed pipe with nitrogen. Stir and heat up. When the temperature rises to 100°C, slowly add 400g of propylene oxide to control the reaction temperature at 120°C and the pressure at 0.4Mpa. After reacting for 4 hours, aging for 1 hour and cooling down to 100°C. Then, 100 g of ethylene oxide was added into the feed tank, and the reaction was carried out at a temperature of 120° C. and a pressure of 0.4 MPa. After reacting for 2 hours, age for 1 hour to obtain polyether A, the structural formula of which is shown in Formula II, where m is 21 and n is 7.

[0038] In the above synthesis method, the mass ratio of initiator to epoxy compound is 1:50, the mass ratio of propylene oxide to ethylene oxide is 4:1, and the mass ratio of KOH to epoxy c...

Embodiment 2

[0045] Embodiment 2, the synthesis of demulsifier B

[0046] (1) Synthesis of polyether

[0047] 4g of the above starter and 2.5g of KOH were added to the autoclave; the reactor system was sealed, and the air in the autoclave, feed tank and feed pipe was replaced with nitrogen. Stir and heat up, when the temperature rises to 100°C, slowly add 300g of propylene oxide, control the reaction temperature at 140°C, and the pressure at 0.3Mpa. After reacting for 5 hours, aging for 1 hour and cooling down to 100°C. 100g of ethylene oxide was added into the feed tank, and the reaction was carried out at a temperature of 140°C and a pressure of 0.3Mpa. After reacting for 3 hours, age for 1 hour to obtain polyether B, the structural formula of which is shown in Formula II, wherein m is 40 and n is 18.

[0048] In the above synthesis method, the mass ratio of initiator to epoxy compound is 1:100, the mass ratio of propylene oxide to ethylene oxide is 3:1, and the mass ratio of KOH to epo...

Embodiment 3

[0055] Embodiment 3, the synthesis of demulsifier C

[0056] (1) Synthesis of polyether

[0057] Add 1 g of the above initiator and 1 g of KOH to the autoclave; seal the autoclave system, and replace the air in the autoclave, feed tank, and feed pipe with nitrogen. Stir and heat up, when the temperature rises to 100°C, slowly add 100g of propylene oxide, control the reaction temperature at 130°C, and the pressure at 0.2Mpa. After 4 hours of reaction, it was aged for 1 hour, and the temperature was lowered to 100°C. 100g of ethylene oxide was added into the feed tank, and the reaction was carried out at a temperature of 130°C and a pressure of 0.2Mpa. After reacting for 6 hours, age for 1 hour to obtain polyether C, whose structural formula is shown in Formula II, wherein m is 54 and n is 72.

[0058] In the above synthesis method, the mass ratio of initiator to epoxy compound is 1:200, the mass ratio of propylene oxide to ethylene oxide is 1:1, and the mass ratio of KOH to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com