Neutralization corrosion inhibitor and preparation method and application thereof

A corrosion inhibitor and corrosion inhibitor technology, applied in the field of neutralization corrosion inhibitor and its preparation, can solve the problems of insufficient protective effect, complicated operation process, troublesome post-processing, etc., and achieve good water solubility, simple production process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

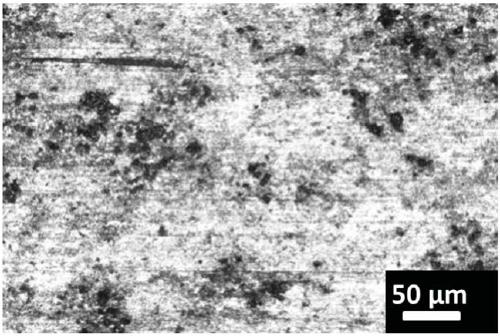

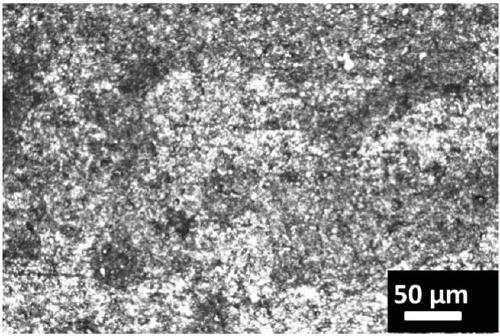

Image

Examples

Embodiment 1

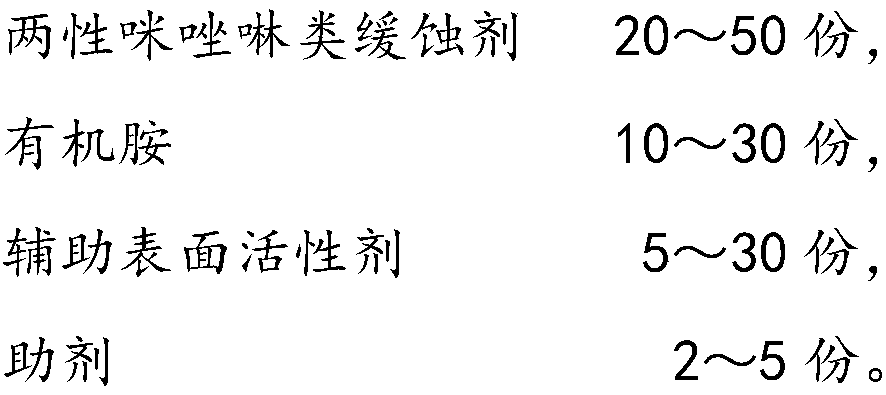

[0038] A neutralizing corrosion inhibitor, comprising raw material components and parts by weight: 20 parts of disodium cocoamphodiacetate, 10 parts of ethylenediamine, 5 parts of sodium cetylbenzenesulfonate, fatty alcohol 5 parts of polyoxyethylene ether, 2 parts of butynediol.

Embodiment 2

[0040] A neutralizing corrosion inhibitor, comprising raw material components and parts by weight: 50 parts of sodium lauroamphoacetate, 30 parts of thiophene, 5 parts of sodium dodecylsulfonate, and 5 parts of potassium iodide.

Embodiment 3

[0042] A neutralizing corrosion inhibitor, comprising raw material components and parts by weight: 30 parts of disodium lauroamphodiacetate, 5 parts of trimethylamine as an organic amine, 10 parts of ethylenediamine, 5 parts of thiourea, auxiliary The surfactant is 10 parts of cetyltrimethylammonium bromide, and the auxiliary agents are propynyl alcohol and potassium iodide, wherein, there are 2 parts of propynyl alcohol and 2 parts of potassium iodide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com