Method for measuring catalyst abrasion resisting capability

A catalyst and anti-wear technology, which is applied in the direction of testing wear resistance, measuring devices, particle size analysis, etc., can solve the problems of complex structure and measurement operation of the measurement device, inability to completely distinguish between coarse and fine catalyst particles, and poor repeatability of measurement results. Achieve the effects of good discrimination ability, good repeatability, simple structure and measurement operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

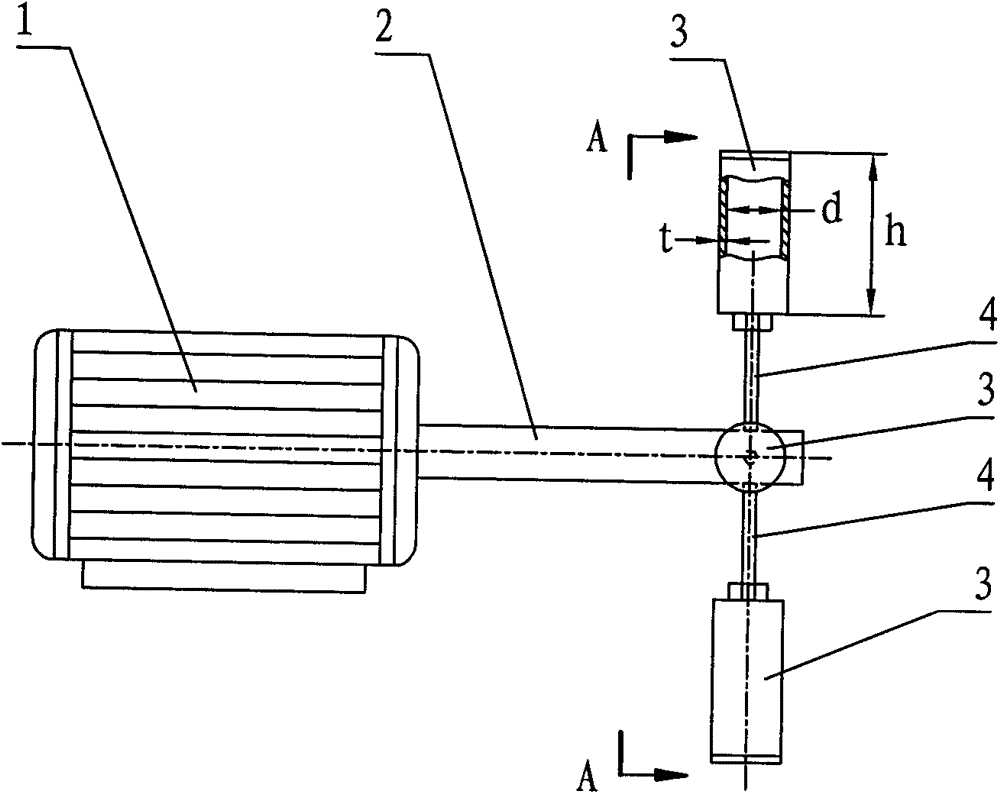

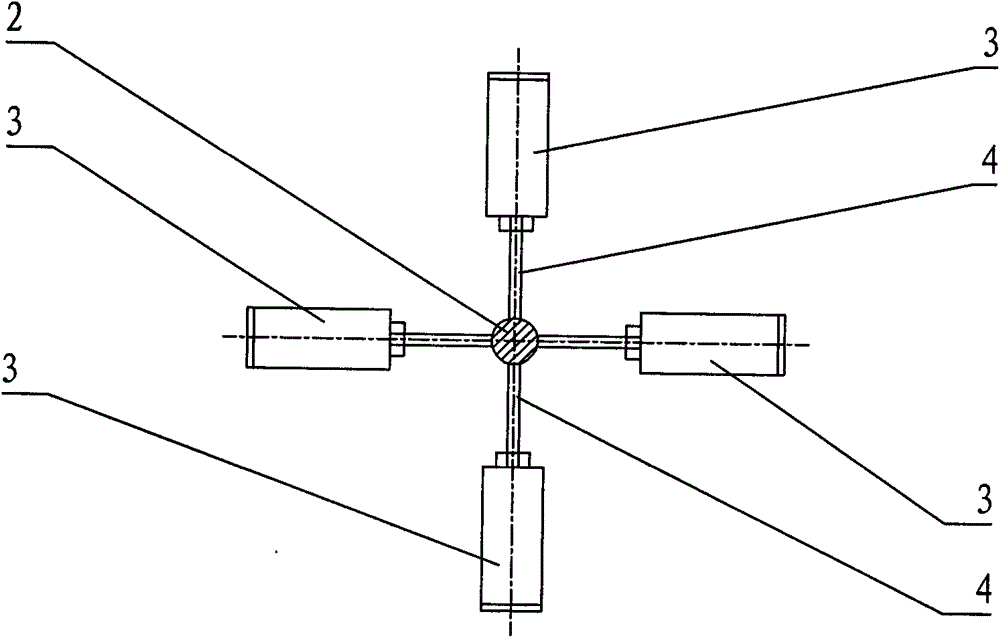

[0022] Measure the anti-wear ability of two kinds of different petroleum processing FCC catalysts by the device and method of measuring catalyst anti-wear ability of the present invention, adopt figure 1 and figure 2 Catalyst wear device shown. Both catalysts are ZSM-5 molecular sieve catalysts, which are respectively referred to as catalyst A and catalyst B; two catalyst samples are taken from each catalyst, which are respectively referred to as catalyst sample A1, catalyst sample A2, catalyst sample B1, and catalyst sample B2. A total of 4 catalyst samples were placed in the inner cavity of each worn tube.

[0023] The motor is an adjustable speed motor with a rotating speed of 60 rpm and a rotation time of 8 hours (that is, the wear time of the four catalyst samples is 8 hours). The heights of the four wear tubes are all 50 cm, the diameters are all 5 cm, and the wall thicknesses are all 2 mm. The volume of each wear tube cavity is equal, and the volume of the loaded ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com