Ageing oil demulsifier and preparation method thereof

An oil demulsifier and demulsifier technology, applied in the direction of dehydration/demulsification by chemical methods, can solve the problems of poor demulsification effect, long dehydration time, and few single-dose varieties, and achieve high dehydration efficiency, small toxic and side effects, Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

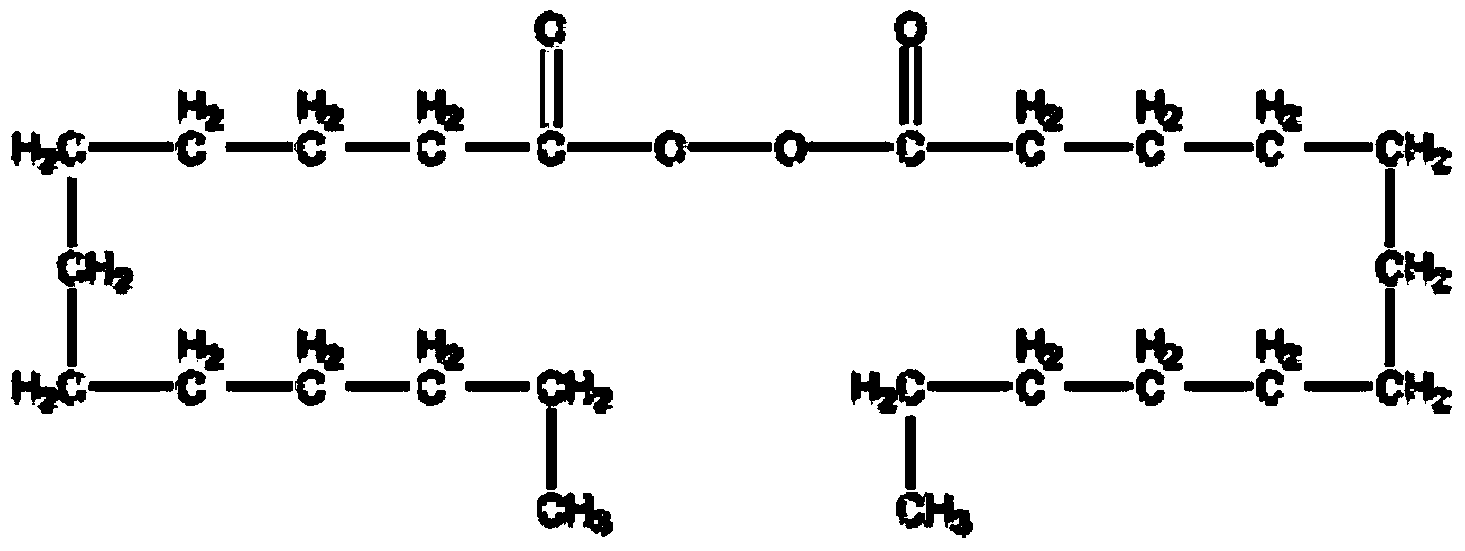

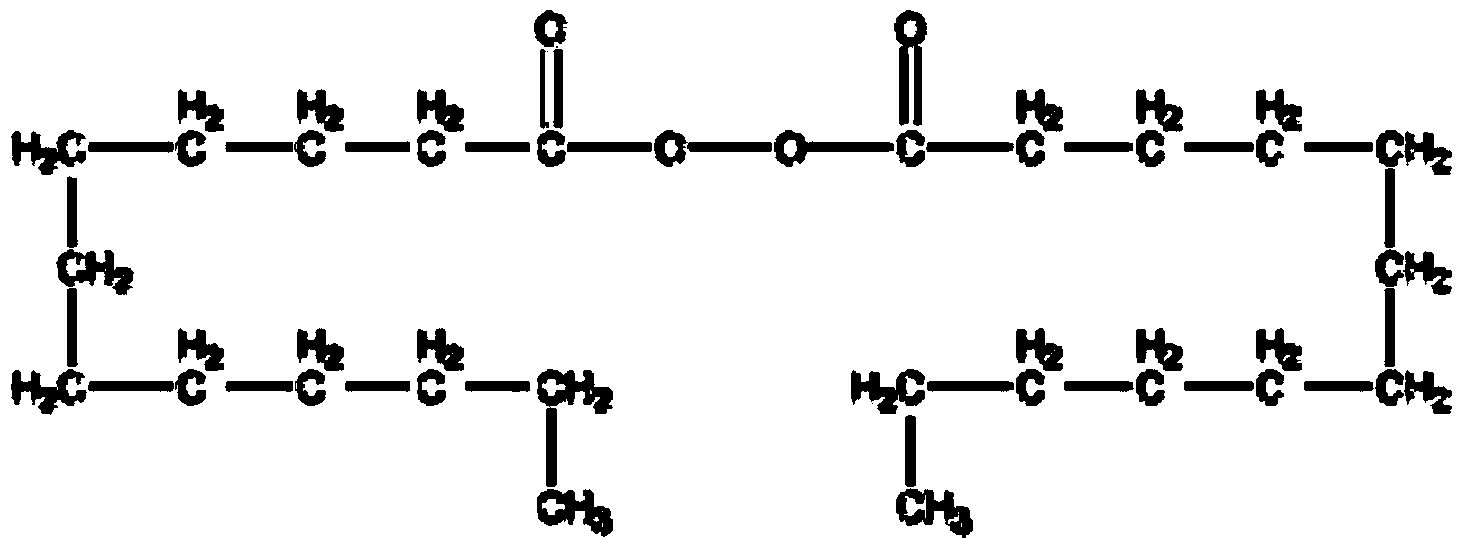

[0019] An aging oil demulsifier, which is composed of mixed acid, demulsifier monomer and initiator, and its composition ratio is: the mixed acid is composed of acrylic acid and maleic anhydride, the molar ratio of acrylic acid and maleic anhydride is 1:1.5, mixed The molar ratio of the acid to the demulsifier monomer alkyl phenolic resin-polyoxypropylene polyoxyethylene ether is 0.5:1.5, and the initiator lauroyl peroxide is 8% of the mass of the mixed acid. Initiator is free radical polymerization initiator lauroyl peroxide, its structural formula is

[0020]

Embodiment 2

[0022] An aging oil demulsifier, which is composed of mixed acid, demulsifier monomer and initiator, and its composition ratio is: mixed acid is composed of acrylic acid and maleic anhydride, the molar ratio of acrylic acid and maleic anhydride is 3:0.5, mixed The molar ratio of the acid to the demulsifier monomer alkylphenolic resin-polyoxypropylene polyoxyethylene ether is 1.7:0.5, and the initiator lauroyl peroxide is 12% of the mass of the mixed acid. All the other are with embodiment 1.

Embodiment 3

[0024] A kind of preparation method of aged oil demulsifier, process comprises: acrylic acid and maleic anhydride are 1:1.5 by molar ratio to prepare mixed acid, mixed acid and demulsifier monomer alkyl phenolic resin-polyoxypropylene polyoxyethylene ether The molar ratio is 1.7:1.5, add lauroyl peroxide free radical polymerization initiator with 12% mixed acid mass, and polymerize at 100°C for 1h, then raise the temperature to 150°C for esterification reaction, esterification Reaction for 3 hours to obtain aging oil demulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com