Dirty oil mud separating method and device

A separation equipment and separation method technology, applied in the field of sludge separation method and equipment, environmental protection equipment, can solve the problems of low recycling rate, helpless enterprises, secondary environmental pollution, etc., to achieve large processing capacity, wide application range, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

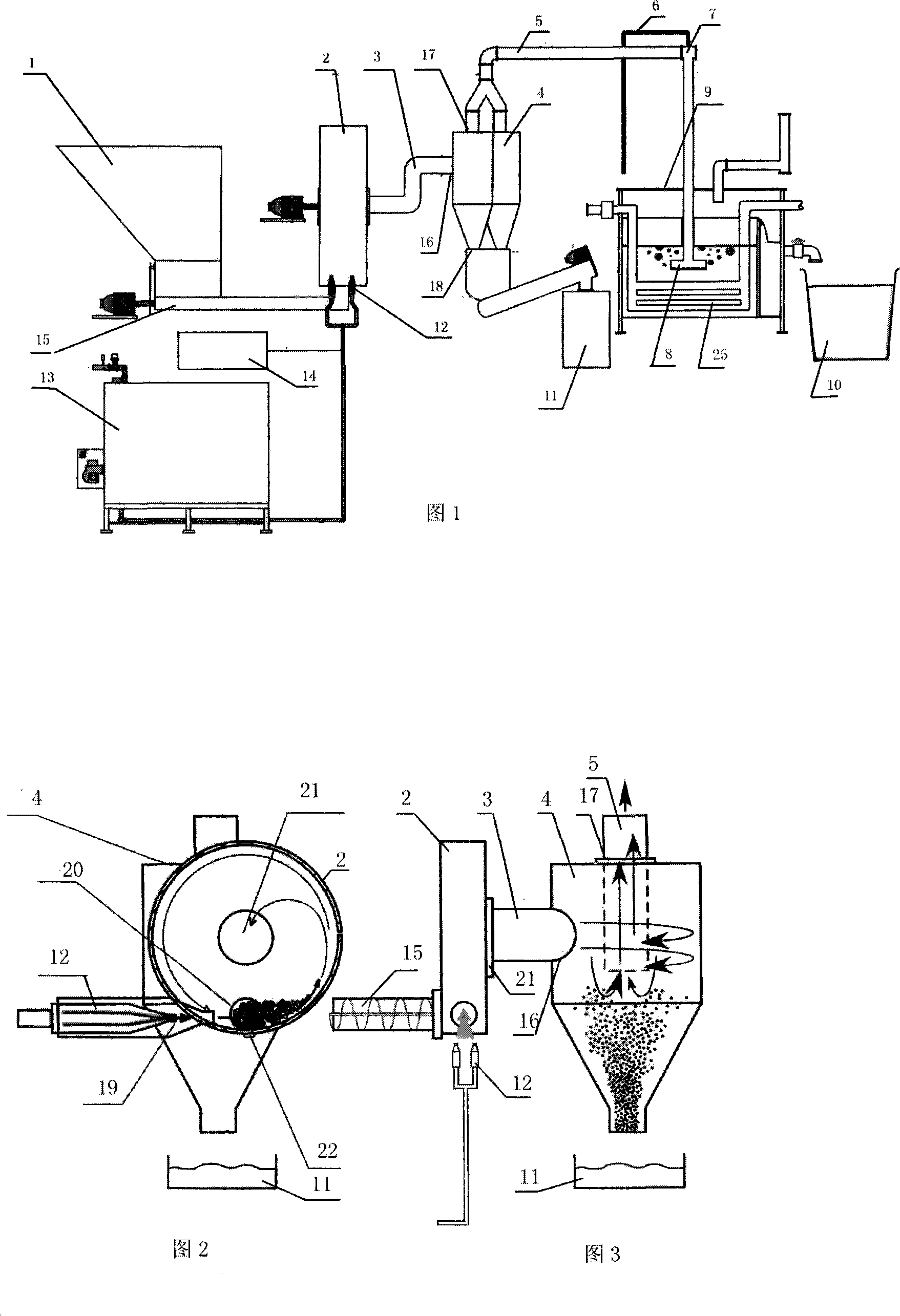

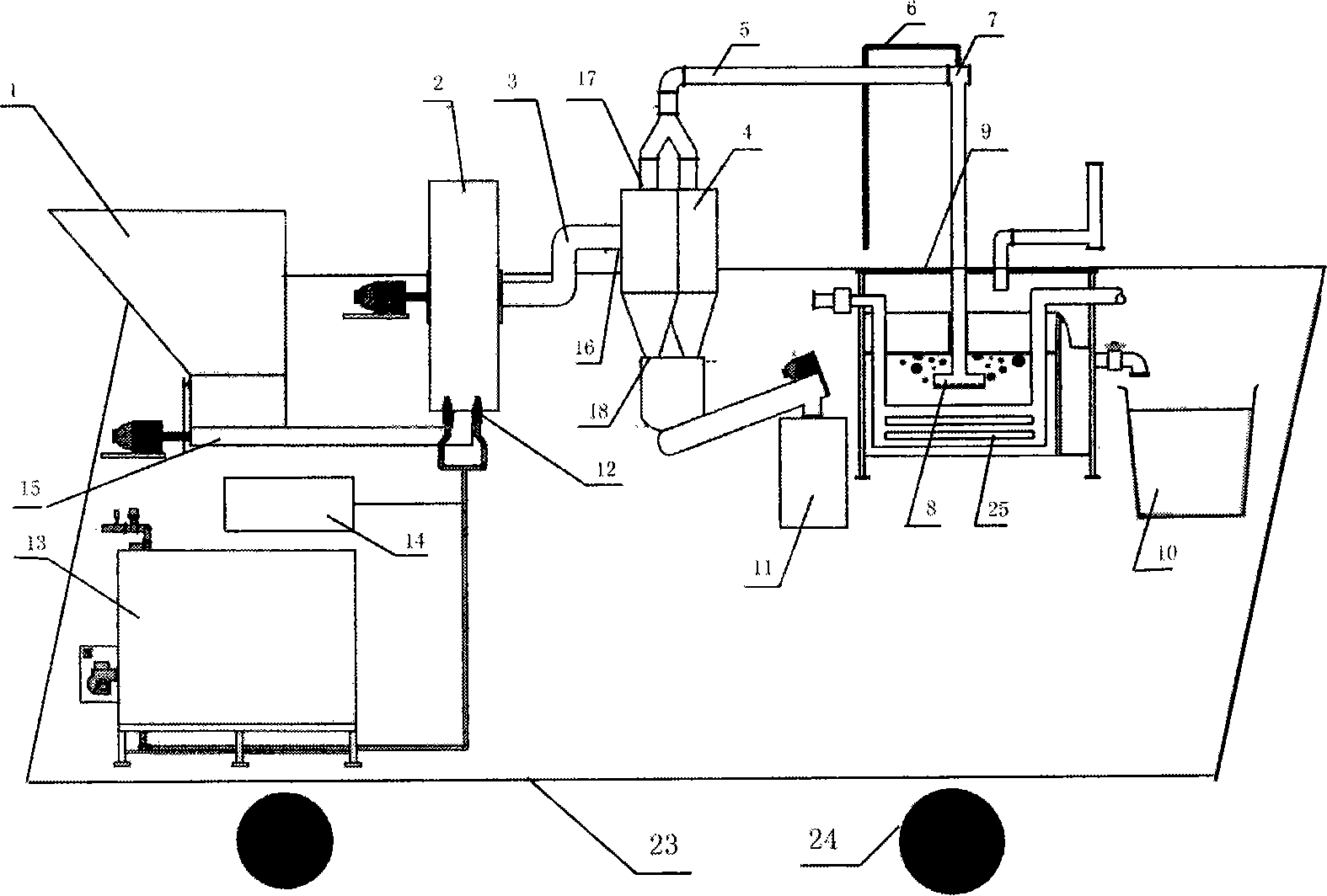

[0037] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0038] A kind of sewage sludge separation method, its concrete steps are:

[0039] (1) Use superheated steam boiler 13 to heat water steam to superheated steam above 500°C; mainly use superheated steam (500°C-700°C), and all processing energy in the treatment process is obtained from superheated steam.

[0040] (2) Spray onto the sludge through the nozzle 12, and the steam ejected from the outlet 19 of the nozzle reaches Mach 2, collides with the sludge in an instant, and the sludge is pulverized into fine particles;

[0041] (3) Instant evaporation and sublimation of water and oil in sludge;

[0042] (4) moisture and oil are separated from solid particles by cyclone separator 4;

[0043] (5) Water and oil are cooled and liquefied by water spraying;

[0044] (6) The liquefied water and oil a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com