Preparation method for alumina carrier

A kind of technology of alumina carrier and preparation process, applied in the direction of catalyst carrier, chemical instrument and method, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of high raw material cost and production cost, poor mechanical strength of carrier, preparation Problems such as complex process, to achieve the effect of small amount of pore expander, good mechanical strength and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

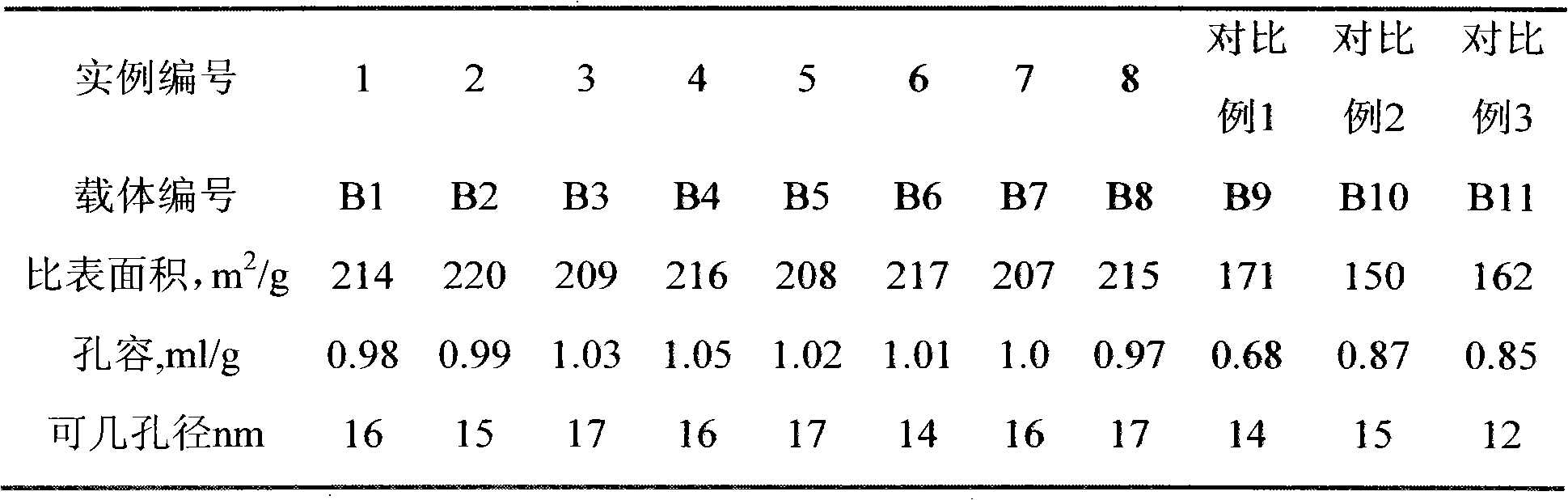

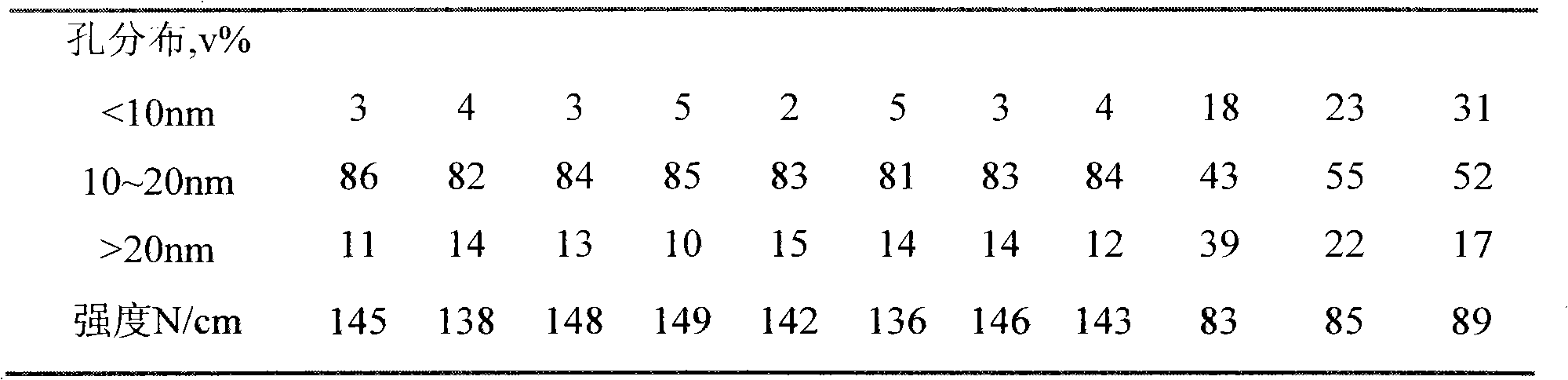

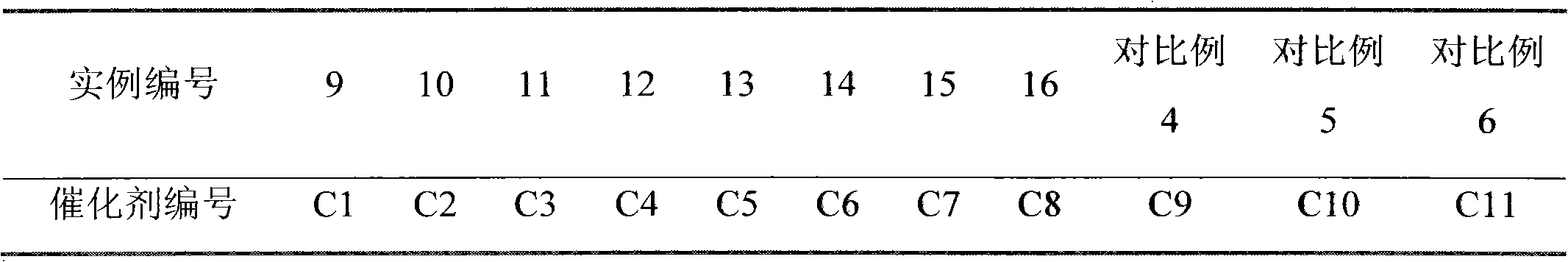

Examples

example 1

[0028] Take by weighing pseudo-boehmite dry rubber powder (produced by Shenyang Catalyst Factory, alumina dry basis content 65%) 100g is placed in autoclave, add 100ml deionized water, autoclave is sealed and is placed in baking oven and heats, and control heating rate is 10℃·min -1 After the temperature rose to 180°C, the temperature was maintained for 3 hours, and then naturally cooled to room temperature. After filtration, the filter cake was dried at 120°C for 1 hour. Pseudo-boehmite after drying and 1.5g concentration are the nitric acid of 65% by weight, 7g carbon black powder, 2g field turnip powder and 75g deionized water mix evenly, extrude into the clover-shaped bar of diameter 1.8mm on the screw extruder , dried at 120° C. for 3 hours, and baked the dried molded product at 700° C. for 3 hours to obtain the alumina carrier B1 provided by the present invention.

example 2

[0030] Same as Example 1, except that the temperature was raised to 110° C. and kept at the temperature for 4 hours, and the amount of deionized water added was 20 ml to obtain the carrier B2 provided by the present invention.

example 3

[0032] Same as Example 1, except that the temperature was raised to 300° C. and kept at the temperature for 2 hours, and the amount of deionized water added was 150 ml to obtain the carrier B3 provided by the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com