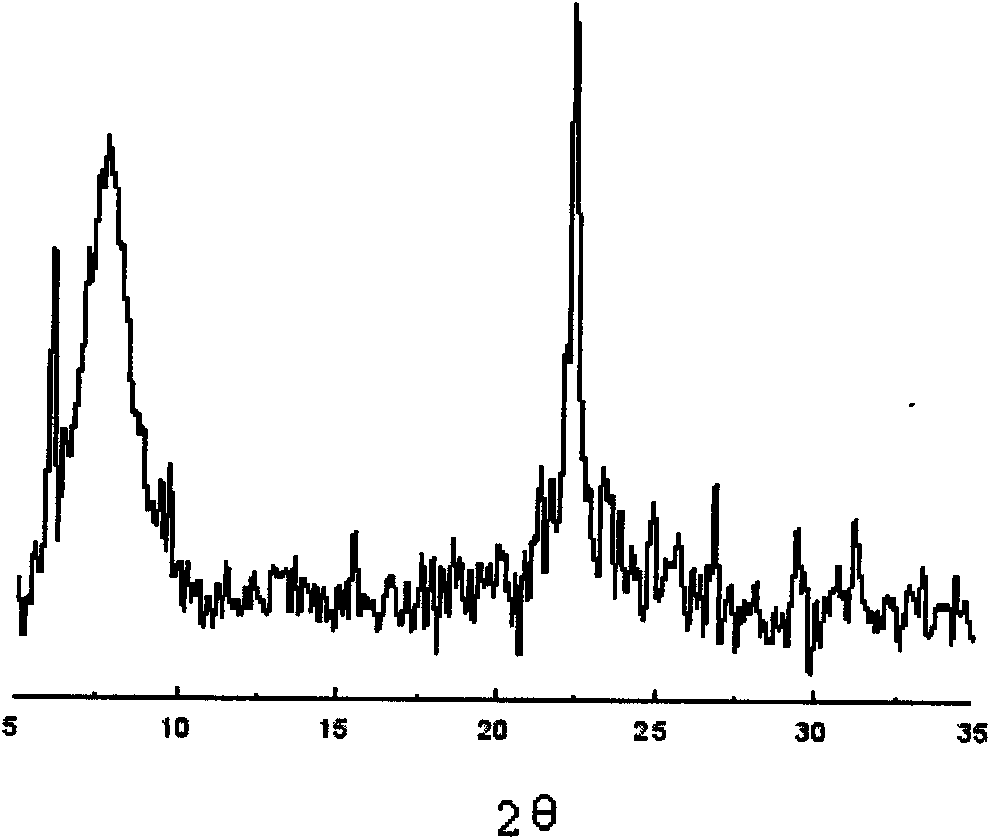

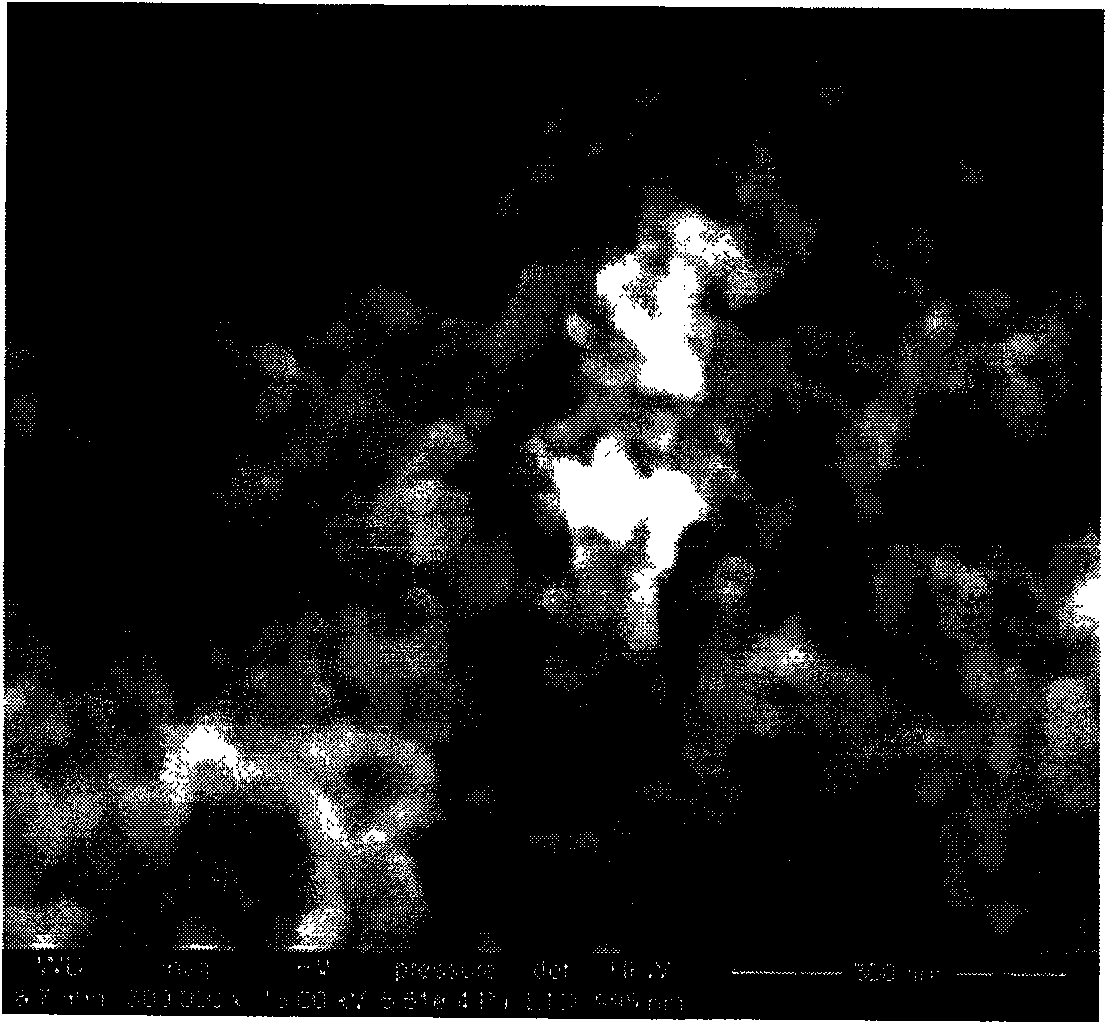

Composite zeolite molecular sieve preparing method containing Y and Beta zeolite structures

A technology of composite zeolite and molecular sieve, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problem of difficult symbiosis or eutectic growth in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Option One:

[0020] Take 4.9ml of deionized water and put it in a 25ml beaker. Weigh 0.226g of sodium aluminate and slowly add it into the above-mentioned beaker under magnetic stirring to make it dissolve. Weigh 0.84g of sodium hydroxide into the beaker, stir to dissolve it, and then slowly add 1.7ml of silica sol after it cools down, stir vigorously until uniform, continue to stir for 5min, seal and store for 18h to obtain the seed gel.

[0021] Take 3.2ml of deionized water and put it in a 25ml beaker. Weigh 0.226g of sodium aluminate and slowly add it into the above-mentioned beaker under magnetic stirring to make it dissolve. Weigh 0.25g of sodium hydroxide into the beaker, stir to dissolve it, wait for it to cool down, then slowly add 0.9ml of silica sol, and stir vigorously for 30min. Measure 1.0ml of the seed gel prepared in the previous step, and stir vigorously for 25min. Then transfer the solution into an autoclave lined with polytetrafluoroethylene and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com