High temp corrosion inhibitor and its preparation method and application

A high-temperature corrosion inhibitor and corrosion inhibitor technology, applied in the field of high-temperature corrosion inhibitors, can solve problems such as poor corrosion inhibition effect and unstable performance of high-temperature corrosion inhibitors, and achieve improved activation energy, low cost, and cheap raw materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

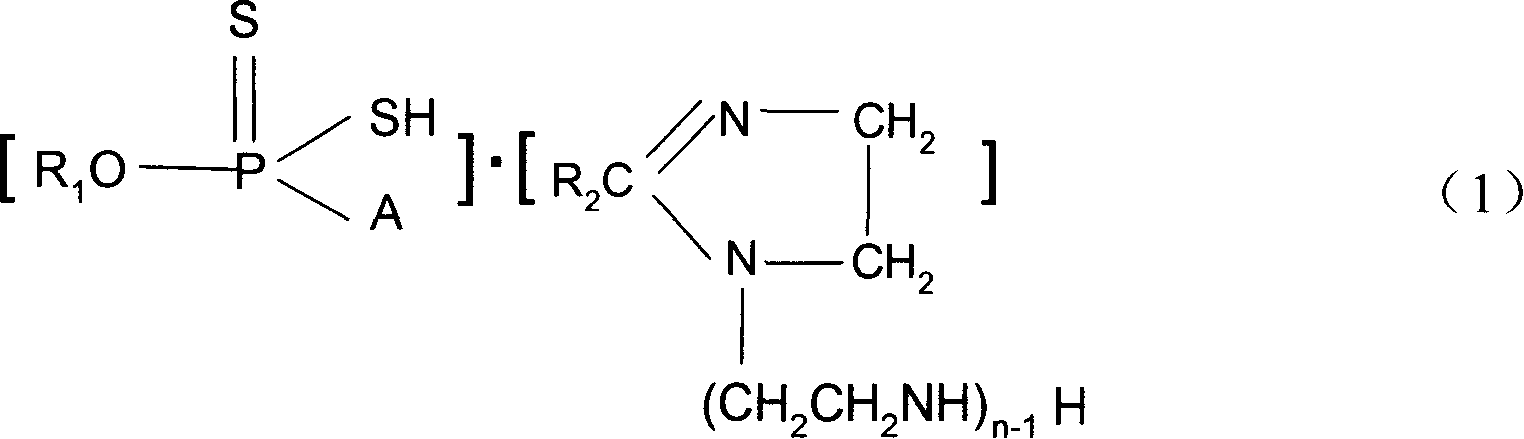

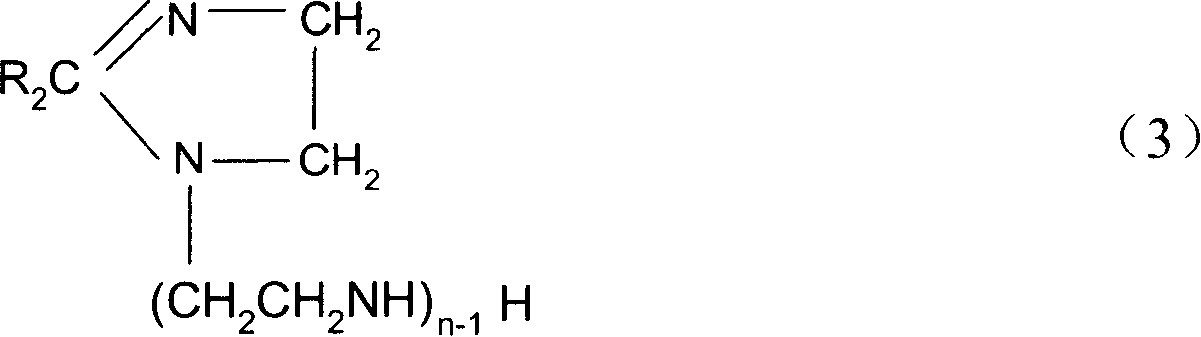

[0035] Structures and preparation methods of novel compounds A1 and B1.

[0036] 1. The structural formula of novel compound A1 is formula (5), and the structural formula of B1 is formula (6):

[0037]

[0038] 2. Preparation method

[0039] (1) Put 260 grams of isooctyl alcohol and 110 grams of toluene into a 500 ml four-necked flask equipped with a stirrer, a thermometer and a condenser. Start the stirring device and open the condensed water of the condenser at the same time, then add 110 grams of phosphorus pentasulfide, and when the temperature is raised to 120° C., keep the temperature constant for 5 hours.

[0040](2) 160 grams of oleic acid, 90 grams of triethylenetetramine, and 60 grams of xylene were simultaneously added to another 500 ml four-neck flask equipped with a stirrer, a thermometer, a water separator, and a condenser. Heat up to 200°C at 10°C / h, dehydrate and remove solvent, keep the temperature for 8 hours, cool to 100°C, add the reaction product of s...

Embodiment 2

[0042] Structures and preparation methods of novel compounds A2 and B2.

[0043] 1. The structural formula of novel compound A2 is formula (7), and the structural formula of B2 is formula (8):

[0044]

[0045] 2. Preparation method

[0046] (1) Put 150 grams of n-butanol and 70 grams of xylene into a 500ml four-neck flask equipped with a stirrer, a thermometer and a condenser. Start the stirring device and open the condensed water of the condenser at the same time, then add 130 grams of phosphorus pentasulfide, and when the temperature is raised to 160° C., keep the temperature constant for 8 hours.

[0047] (2) 140 grams of stearic acid, 140 grams of diethylenetriamine, and 90 grams of benzene were simultaneously added to another 500 ml four-neck flask equipped with a stirrer, a thermometer, a water separator, and a condenser. Heat up to 240°C at 10°C / h, dehydrate and remove solvent, keep the temperature for 6 hours, cool to 120°C, add the reaction product of step (1), ...

Embodiment 3

[0049] Structures and preparation methods of novel compounds A3 and B3.

[0050] 1. The structural formula of novel compound A3 is formula (9), and the structural formula of B3 is formula (10):

[0051]

[0052] 2. Preparation method

[0053] (1) Put 150 grams of dodecyl alcohol and 90 grams of xylene into a 500 ml four-necked flask equipped with a stirrer, a thermometer and a condenser. Start the stirring device and open the condensed water of the condenser at the same time, then add 150 grams of phosphorus pentasulfide, and when the temperature is raised to 150° C., keep the temperature constant for 6 hours.

[0054] (2) Add 240 grams of dodecenylsuccinic acid, 50 grams of pentaethylenehexamine, and 70 grams of toluene to another 500 ml four-necked flask equipped with a stirrer, a thermometer, a water separator, and a condenser at the same time. Raise the temperature to 220°C at 10°C / h, dehydrate and remove the solvent, keep the temperature constant for 5 hours, cool to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com