Preparation method for supported Mo-based oxidation and desulfurization catalyst

A technology of oxidative desulfurization and catalyst, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, molecular sieve catalysts, etc., can solve problems such as loss of oil products, difficulty in completely separating oil from water, and environmental pollution. To achieve the effect of enhancing the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of citric acid modified MoO 3 / SiO 2 catalyst

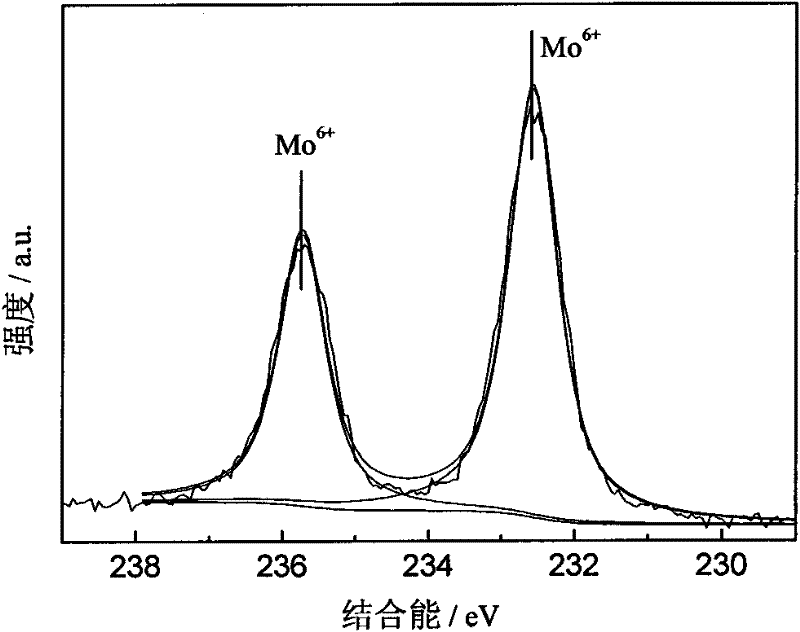

[0021] Firstly, supported MoO was prepared by isometric impregnation method 3 / SiO 2 Catalyst: Weigh 0.920g of ammonium molybdate and dissolve it in 9g of deionized water to make a solution, add dropwise to 3g of white carbon black, stir evenly, let stand at room temperature for 12h, dry at 120°C for 4h, and heat up at a rate of 2°C / min to 500°C, after calcination for 5h, SiO was prepared 2 Loaded MoO 3 Catalyst, denoted as MoO 3 / SiO 2 , where MoO 3 The loading capacity is 20% by mass fraction.

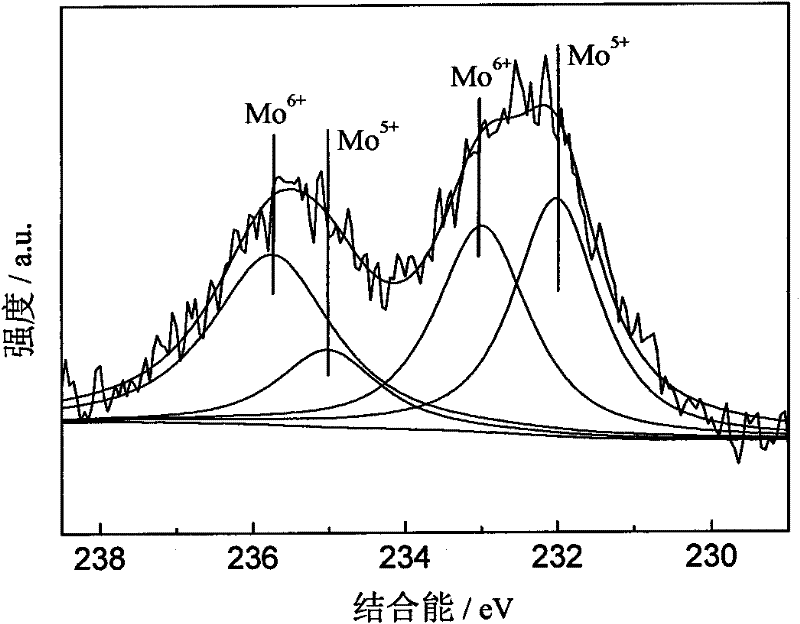

[0022] Then weigh 0.3g of citric acid and dissolve it in 1g of deionized water to form a solution, and add it dropwise to 1g of prepared MoO 3 / SiO 2 In the sample, stir evenly, stand at room temperature for 4 hours, and dry at 100°C for 2 hours. Then, the catalyst was subjected to a temperature-programmed heat treatment under a nitrogen atmosphere: at room temperature, the temperature was raised to 120°C a...

Embodiment 2

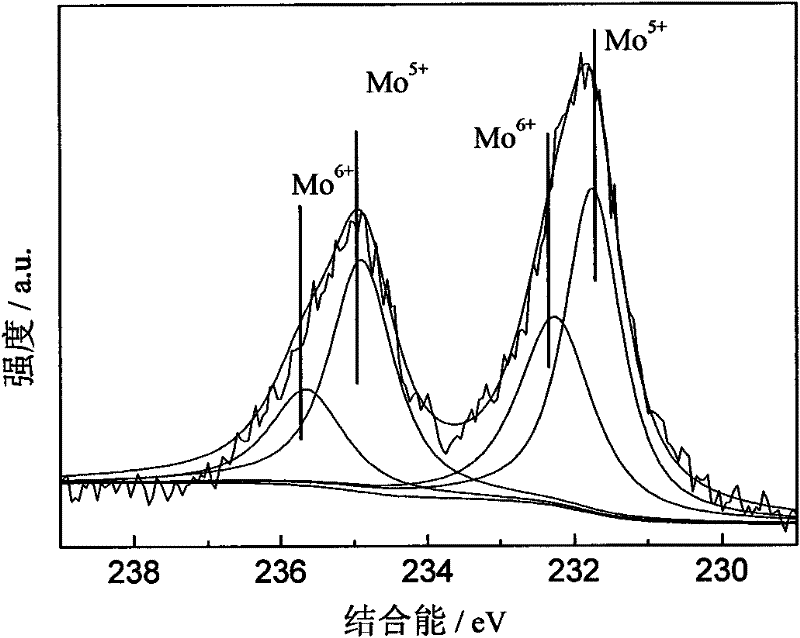

[0024] Preparation of oxalic acid modified MoO 3 / SiO 2 Catalyst: Weigh 0.2g of oxalic acid and dissolve it in 1g of deionized water to make a solution, add it dropwise to 1g of prepared MoO 3 / SiO 2 In the sample, stir evenly, stand at room temperature for 4 hours, and dry at 100°C for 2 hours. Under a nitrogen atmosphere, the catalyst was subjected to temperature-programmed heat treatment: at room temperature, the temperature was raised to 150°C at a rate of 2°C / min, and kept for 1 hour, then raised to 250°C at a rate of 2°C / min, kept for 1 hour, and then heated at a rate of 2°C / min. Raise the temperature to 300°C at a rate of min and keep it for 1 hour to prepare a catalyst, which is denoted as OA-MoO 3 / SiO 2, the loading amount of oxalic acid is 20% by mass fraction. Depend on image 3 It can be seen that in OA-MoO 3 / SiO 2 Simultaneously observed Mo on the surface 6+ and low-valence Mo 5+ species.

Embodiment 3

[0026] The catalyst in the embodiment 1 or 2 of 0.2g is loaded in the internal diameter 8mm fixed-bed reactor, with the toluene solution of the dibenzothiophene of mass fraction 0.2% as simulated oil product, with hydroxycumene peroxide as oxidant Continuous oxidative desulfurization reaction. Other reaction conditions are: O / S molar ratio = 4, normal pressure, reaction temperature 50°C, WHSV = 32h -1 . Depend on Figure 4 It can be seen that the oxidative desulfurization activity of the catalyst modified by citric acid or oxalic acid is higher than that of MoO 3 / SiO 2 There is a significant improvement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com