Preparation method for reticulate structural part provided with component and pore double gradient transition layers

A network structure, double gradient technology, applied in the field of additive manufacturing, can solve the problems of metal implant prosthesis mechanical mismatch, poor osseointegration ability, low interface bonding force, etc., to improve osseointegration ability, save cost, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

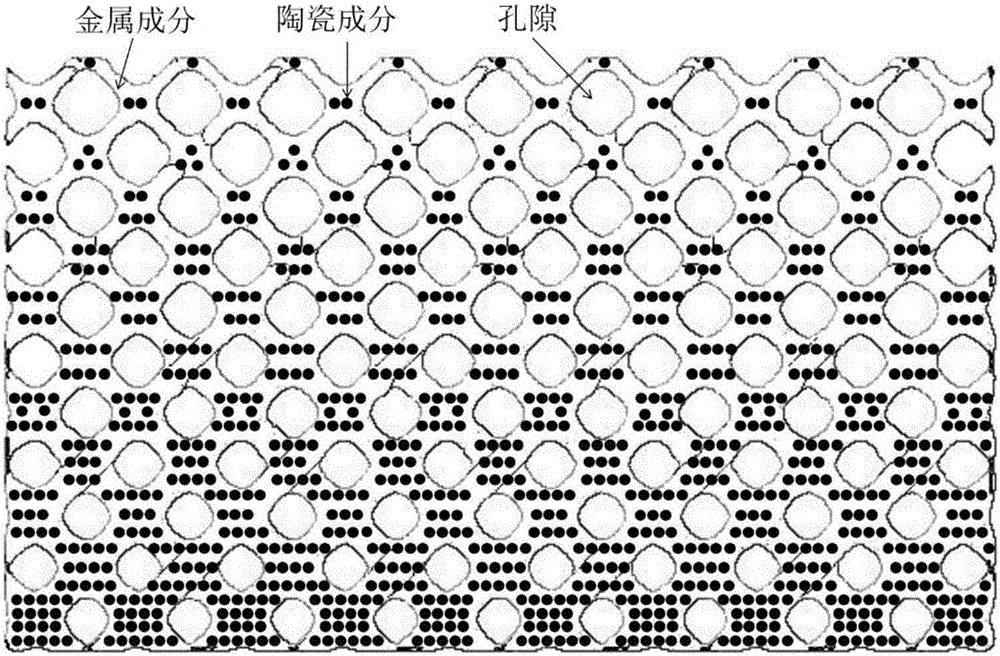

[0030] A method for preparing a network structure with a dual gradient transition layer of composition and pores of the present invention mainly includes the following steps:

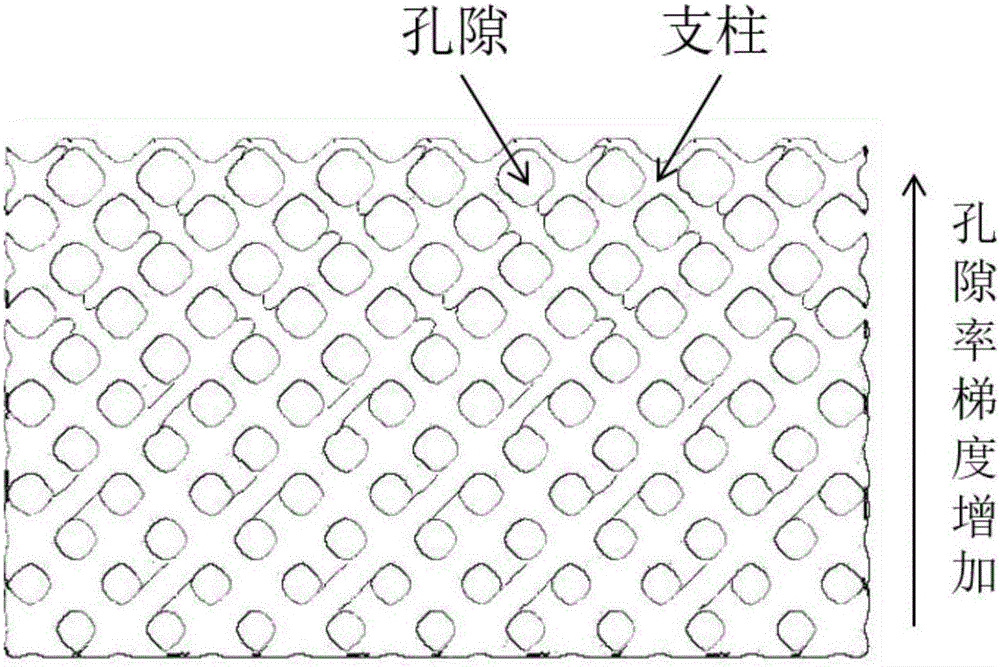

[0031] (1) Use 3D modeling software to design a 3D CAD model with a network structure with gradient pore scales and bionic cell topology, such as figure 1 As shown, the three-dimensional CAD model is sliced and converted into an STL file, the STL file is imported into the SLM forming equipment, the SLM forming equipment is evacuated and a protective atmosphere is introduced, and high-purity argon is preferably used as the protective atmosphere;

[0032] Specifically, the network structure model is one of Cell unit, Cage unit, Cubic unit, Octahedron unit, Diamond unit or Gyroid unit based on the bionic structure. In order to meet the bionic requirements and allow bone cells to have enough space for growth, differentiation and migration, the porosity of the unit gradually changes from 60% to 80% at a ce...

Embodiment 1

[0045] Using the method of the present invention to prepare the network structure of the pure titanium / hydroxyapatite composition and pore controllable double gradient transition layer, the specific steps are as follows:

[0046] 1) Use 3D modeling software to design a 3D CAD model of the Diamond network structure with a gradient change in the pore scale of the bionic unit topology. The porosity of the unit gradually changes from 60% to 80% at a unit interval of 5%, and the unit size is designed to be 2mm , the height of the network structure is set to 10mm; the 3D CAD model is sliced and converted into an STL file, imported into the SLM forming equipment, vacuumed and injected with high-purity argon as a protective atmosphere;

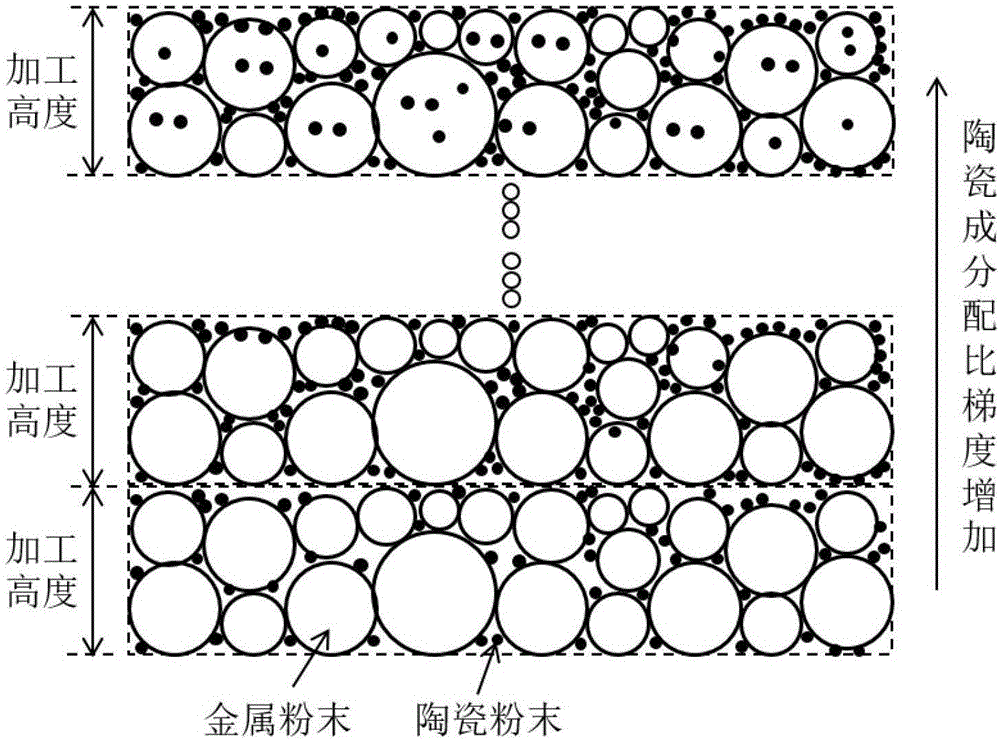

[0047] 2) The multi-component online powder mixing mechanism is used to uniformly mix the pure titanium powder and the hydroxyapatite powder in real time, so that the mass percentage of the hydroxyapatite is 1%, and they are uniformly mixed by an agi...

Embodiment 2

[0052] Using the method of the present invention to prepare the network structure of stainless steel / tricalcium phosphate composition and pore controllable double gradient transition layer, the specific steps are as follows:

[0053] 1) Use 3D modeling software to design a 3D CAD model of the Cubic network structure with a gradient change in the pore scale of the bionic unit topology. The porosity of the unit gradually changes from 60% to 80% at a unit interval of 4%, and the unit size is designed to be 8mm , the height of the network structure is set to 48mm, the 3D CAD model is sliced and converted into an STL file, imported into the SLM forming equipment, vacuumed and injected with high-purity argon as a protective atmosphere;

[0054] 2) The multi-component online powder mixing mechanism is used to uniformly mix the stainless steel powder and the tricalcium phosphate powder in real time, so that the volume percentage of the tricalcium phosphate is 5%, and they are uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com