Preparation method of ferroferric-oxide-based high-performance negative electrode material for lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of expensive raw materials, complicated process, and low yield, and achieve low cost, simple preparation process, and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

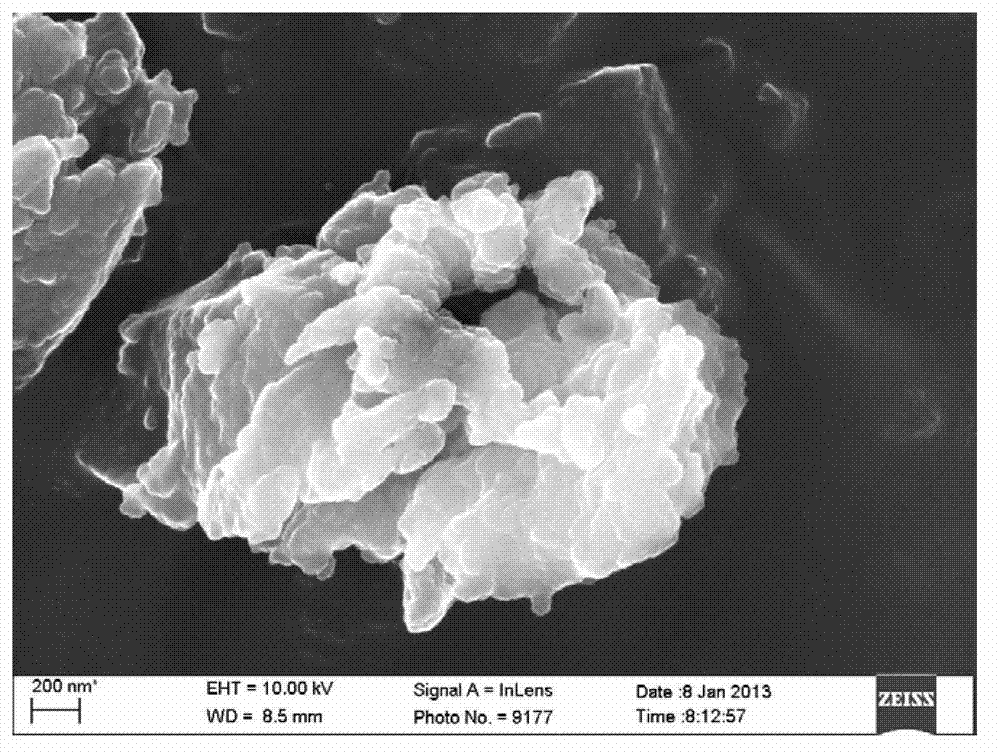

[0034] Weigh 1.35 g FeCl 3 ·6H 2 O was dissolved in 30 ml of ethylene glycol and stirred evenly to form a yellow clear solution, which was designated as solution A. Weigh 3.6 g NaAc and add it to 40 ml ethylene glycol, then add 1 ml polyethylene glycol 200 (PEG200), stir magnetically to form a transparent solution B. Solution B was added dropwise to solution A to form a tan homogeneous solution. The mixture was continuously stirred for 10 min, then 0.3 g of activated carbon was added and dispersed ultrasonically, and finally the obtained suspension was poured into a 100 ml hydrothermal kettle with a polytetrafluoroethylene liner, and heated at 160 o C for 48 h. The black powder obtained by the reaction was centrifuged, washed and vacuum-conditioned at 70 o Dry at C for 6 h, and finally get Fe 3 o 4 / C Composite. The prepared 80 wt.% Fe 3 o 4 / C composite material, 10 wt.% acetylene black and 10 wt.% CMC were mixed evenly to make a slurry, which was evenly coated on co...

Embodiment 2

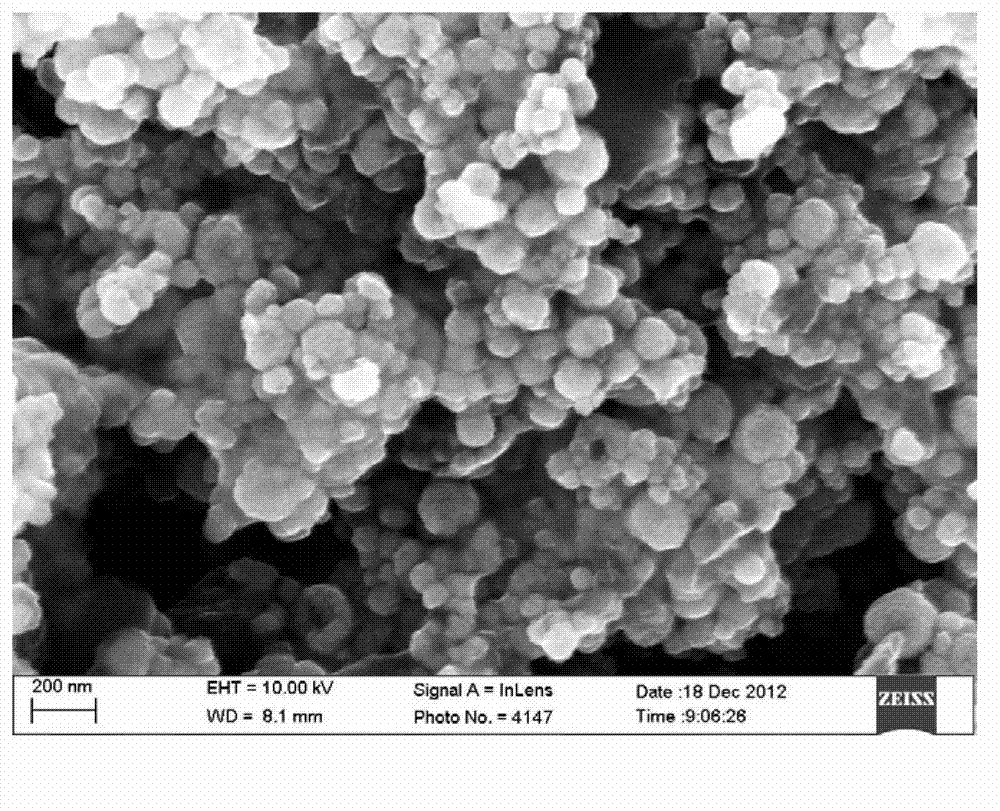

[0037] Weigh 1.35 g FeCl 3 ·6H 2 O was dissolved in 30 ml of ethylene glycol and stirred evenly to form a yellow clear solution, which was designated as solution A. Weigh 3.6 g NaAc and add it to 40 ml ethylene glycol, then add 1 ml polyethylene glycol 200 (PEG200), stir magnetically to form a transparent solution B. Solution B was added dropwise to solution A to form a tan homogeneous solution. The mixture was continuously stirred for 10 min, then 0.5 g of activated carbon was added and dispersed ultrasonically, and finally the obtained suspension was poured into a 100 ml hydrothermal kettle with a polytetrafluoroethylene liner, at 200 o C for 48 h. The black powder obtained by the reaction was centrifuged, washed and vacuumed at 90 o Dry at C for 6 h, and finally get Fe 3 o 4 / C Composite. The prepared 80 wt.% Fe 3 o 4 / C composite material, 10 wt.% acetylene black and 10 wt.% CMC were mixed evenly to make a slurry, which was evenly coated on copper foil, and then v...

Embodiment 3

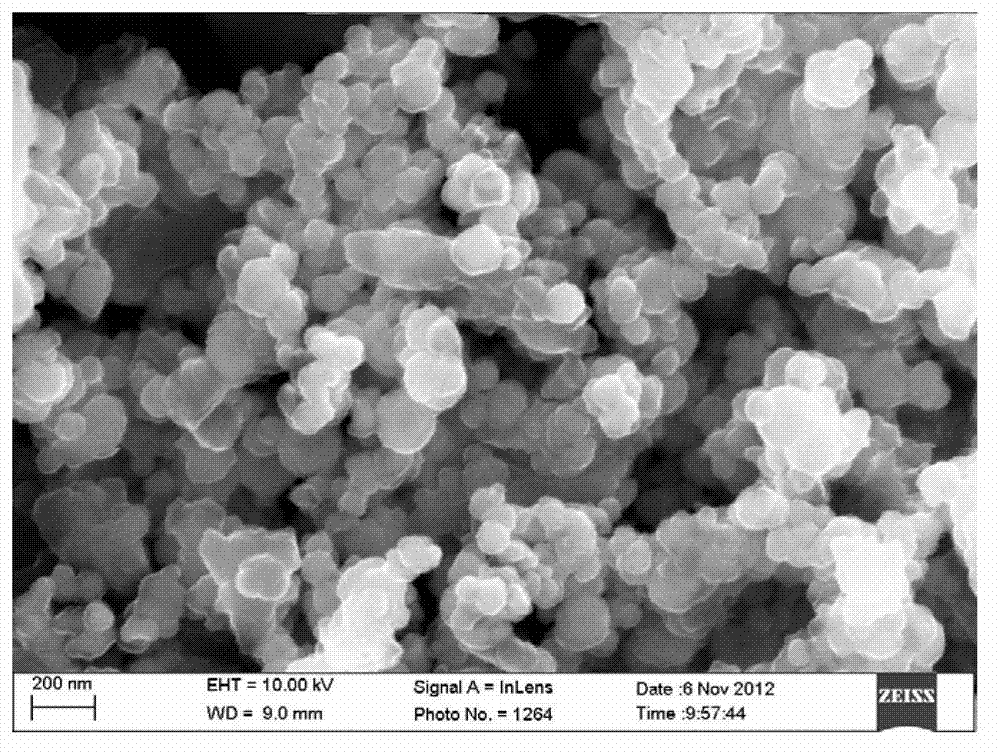

[0040] Weigh 1.35 g FeCl 3 ·6H 2 O was dissolved in 30 ml of ethylene glycol and stirred evenly to form a yellow clear solution, which was designated as solution A. Weigh 3.6 g NaAc and add it to 40 ml ethylene glycol, then add 1 ml polyethylene glycol 200 (PEG200), stir magnetically to form a transparent solution B. Solution B was added dropwise to solution A to form a tan homogeneous solution. The mixture was continuously stirred for 10 min, then 1 g of activated carbon was added and dispersed ultrasonically, and finally the obtained suspension was poured into a 100 ml hydrothermal kettle with a polytetrafluoroethylene liner, and heated at 220 o C for 48 h. The black powder obtained by the reaction was centrifuged, washed and vacuum-conditioned at 70 o Dry at C for 6 h, and finally get Fe 3 o 4 / C Composite. The prepared 80 wt.% Fe 3 o 4 / C composite material, 10 wt.% acetylene black and 10 wt.% CMC were mixed evenly to make a slurry, which was evenly coated on copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com