Nano-paste, self-cleaning coating liquid and thermal insulating coating liquid as well as transparent substrates and preparation methods thereof

A nano-slurry, coating liquid technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of unsatisfactory thickness, high cost, complex film production process, etc., to improve the process, wide application range, The effect of simplifying the coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Nano slurry with self-cleaning function

[0040] The formula of self-cleaning nano-paste is shown in the following table:

[0041] Photocatalyst (Evonik Degussa P25) 10 servings

[0042] Wetting agent (BYK Disperbyk-181) 4 parts Active dispersant (BYK-5410) 6 servings Defoamer (BYK-028) 0.2 parts Anhydrous ethanol (China National Pharmaceutical Group Chemical Reagent Company) 80 servings

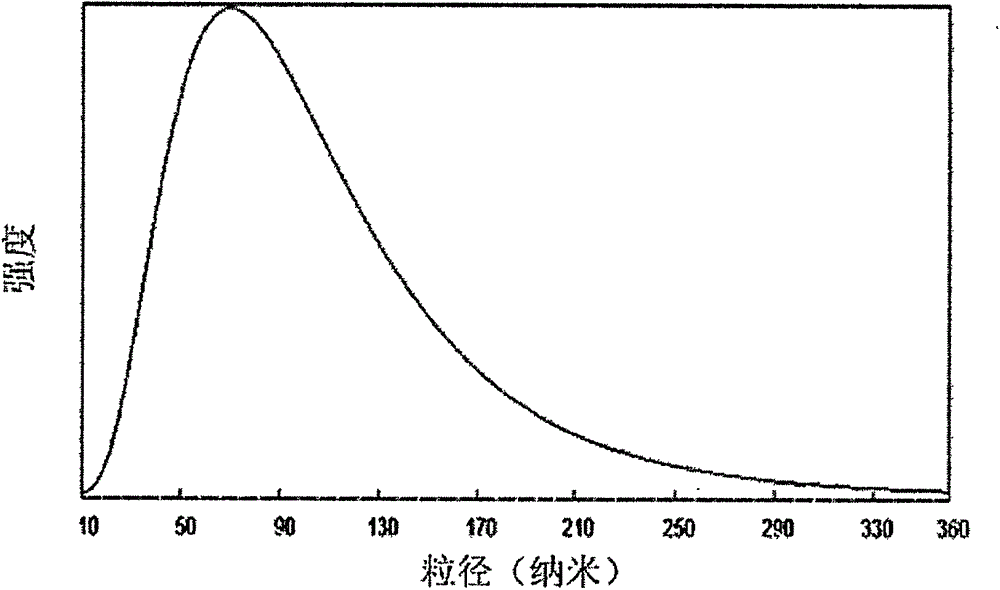

[0043] Preparation method: first dissolve the wetting agent, defoamer and active dispersant in ethanol, add the photocatalyst P25 powder under stirring conditions, and after stirring, sand mill in a sand mill for 3 hours to obtain an average particle size of 95nm (Dynamic Light Scattering Test Results) The particle size distribution of the slurry around figure 1 Shown.

Embodiment 2

[0044] Example 2 Nano-paste with heat insulation function

[0045] The formula of self-cleaning nano-paste is shown in the following table:

[0046] Nano Indium Tin Oxide (Shanghai Zheng Nano ITO-P100) 30 servings Wetting agent (BYK Disperbyk-181) 8 servings Active dispersant (BYK-6190) 10 servings Defoamer (BYK-028) 0.3 copies Anhydrous ethanol (China National Pharmaceutical Group Chemical Reagent Company) 52 servings

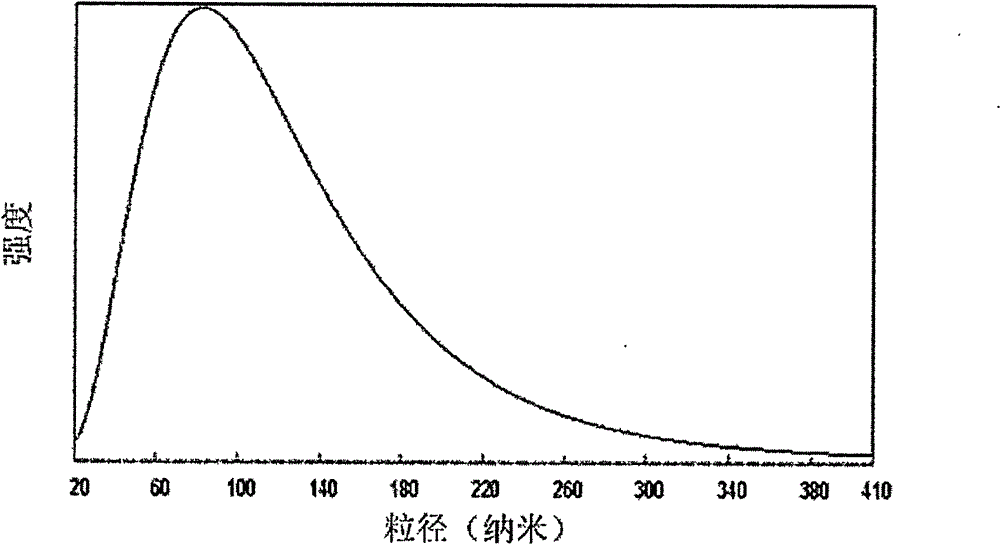

[0047] Preparation method: first dissolve the wetting agent, defoamer and active dispersant in ethanol, add indium tin oxide powder under stirring conditions, and after stirring, sand mill in a sand mill for 3 hours to obtain the average particle size The particle size distribution of the slurry around 83nm (dynamic light scattering test result) is as figure 2 Shown.

Embodiment 3

[0048] Example 3 Self-cleaning glass

[0049] The formula of self-cleaning film coating liquid is shown in the following table:

[0050] Silicone resin (Dow Corning 2-19122) 2 servings Nano-paste with self-cleaning function (Example 1) 5 servings Titanium Dioxide Sol 1 serving Defoamer (BYK-028) 0.1 part Thickener (Dow Chemical RM-8W) 0.3 copies Anhydrous ethanol (China National Pharmaceutical Group Chemical Reagent Company) 80 servings

[0051] Preparation method of self-cleaning coated glass:

[0052] Mix the above-mentioned self-cleaning coating liquid uniformly according to the formula, roll it on the surface of the glass substrate, wait for the surface to dry, and then bake at 150°C for 15 minutes to obtain a transparent self-cleaning film with a thickness of 20 nanometers on the glass surface. Clean the coating to obtain self-cleaning glass.

[0053] The preparation process of the titanium dioxide sol is as follows: dissolve n-tetrabutyl titanate and acetylacetone in et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com