Aromatic terminal hydroxyl chain extender containing acylhydrazone bond, self-repairing polyurethane and preparation method thereof

A hydroxyl-terminated chain extender and aromatic technology, which are used in the field of self-healing polyurethane and its preparation, self-repairing polyurethane, and aromatic hydroxyl-terminated chain extender, can solve the problem that repair units are not easy to uniformly disperse, unfavorable for long-term use of materials, and loss of self-repair. Repair function and other problems, to achieve the effect of good physical and mechanical properties, high self-repairing efficiency, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

[0030] Example 1.1: Preparation of an aromatic hydroxyl-terminated chain extender containing an acylhydrazone bond

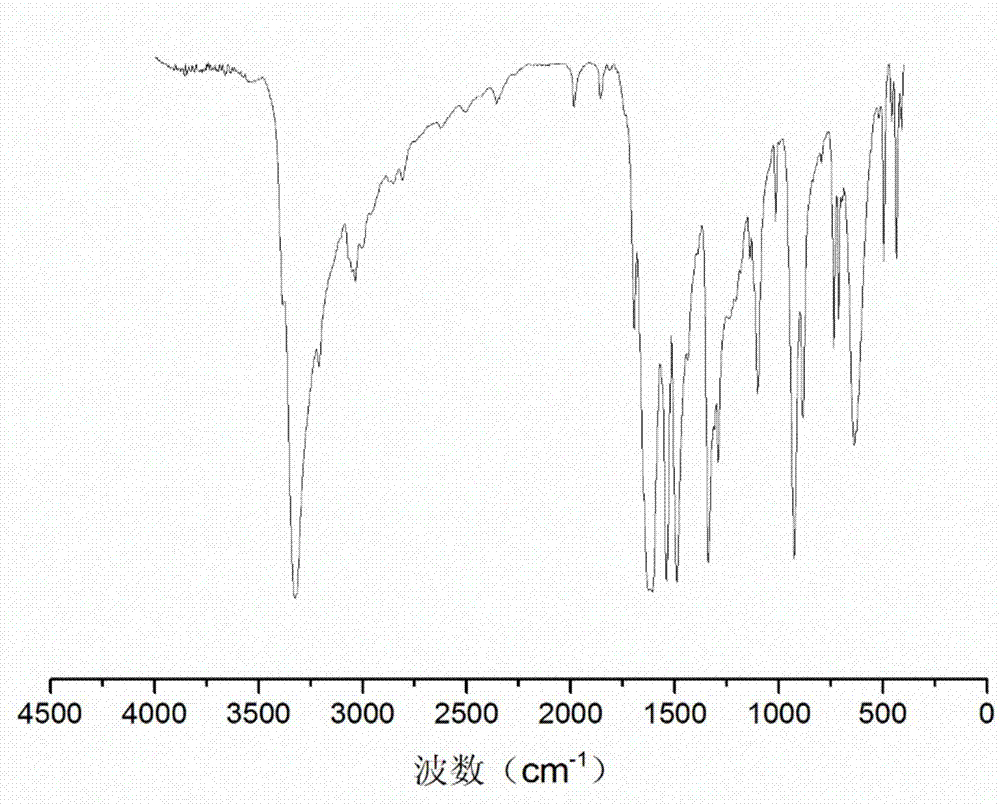

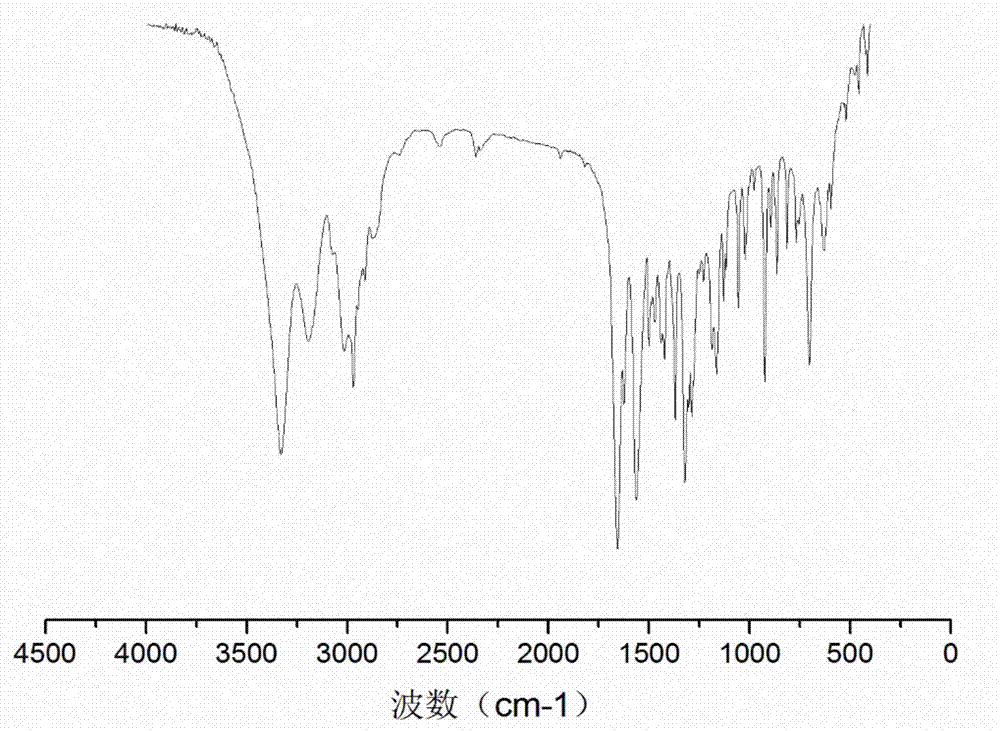

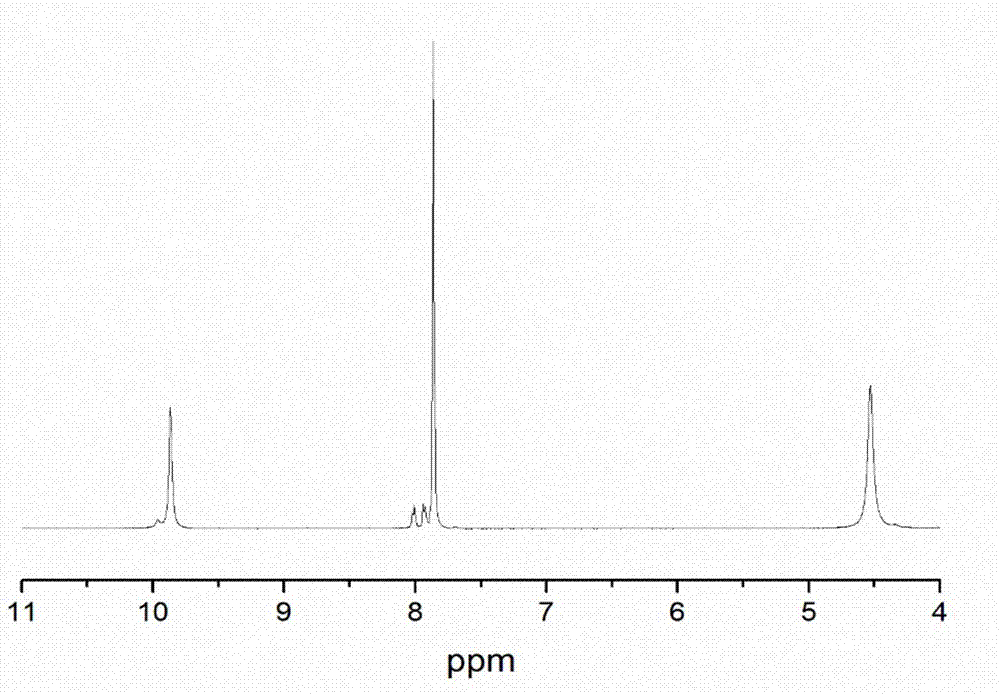

[0031] Take 23.23g of 4-hydroxy-4-methyl-2-pentanone and dissolve in 50.00g of deionized water, and dissolve 19.42g of terephthalic acid dimethylhydrazide in 70.00g of glacial acetic acid. After mixing the two evenly, react at 70°C for 2h under stirring at 250rpm. Filtrate under reduced pressure, and vacuum-dry the resulting product to obtain an aromatic hydroxyl-terminated chain extender containing an acylhydrazone bond. The molecular structure is as shown in formula (1), named 4-hydroxy-4-methyl-2-pentanone Terephthalic acid diformylhydrazone, the product is a white solid powder. Obtain product 33.20g, productive rate 85%, its infrared spectrogram is as image 3 As shown, its NMR spectrum is shown as Figure 4 shown.

[0032]

Embodiment 12

[0033] Example 1.2: Preparation of an aromatic hydroxyl-terminated chain extender containing an acylhydrazone bond

[0034] Dissolve 13.81g of 2,5-dihydroxybenzaldehyde in 90.00g of isopropanol, and dissolve 16.82g of 3,5-dihydroxyphenylhydrazide in 30.00g of glacial acetic acid. Mix the two evenly and react at 50° C. for 4 hours under stirring at 250 rpm. Filtrate under reduced pressure, and vacuum-dry the obtained product to obtain an aromatic hydroxyl-terminated chain extender containing an acylhydrazone bond. The molecular structural formula is shown in formula (2), and it is named as 2,5-dihydroxybenzaldehyde Dihydroxybenzoylhydrazone, the product is light yellow solid powder. The product was obtained in 23.72 g, yield 82.3%.

[0035]

Embodiment 13

[0036] Example 1.3: Preparation of an aromatic hydroxyl-terminated chain extender containing an acylhydrazone bond

[0037] Dissolve 27.62g of salicylic acid in 70.00g of deionized water, and dissolve 42.00g of 3,5-dihydroxyphenylhydrazide in 50.00g of glacial acetic acid. Mix the two evenly and react at 65° C. for 2.5 hours under stirring at 250 rpm. Filtrate under reduced pressure, and vacuum-dry the obtained product to obtain an aromatic hydroxyl-terminated chain extender containing an acylhydrazone bond. , the product is light yellow solid powder. 44.68 g of the product was obtained with a yield of 77.5%.

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com