Process for producing nano titanium dioxide/diatomite composite photocatalytic material

A technology of nano-titanium dioxide and composite photocatalysis, which is applied in the direction of physical/chemical process catalysts, chemical/physical processes, catalyst activation/preparation, etc., can solve the problems of unsatisfactory advanced treatment of exhaust gas and the inability to completely remove harmful substances, etc., and achieve improvement Photocatalytic performance, ideal effect, and the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

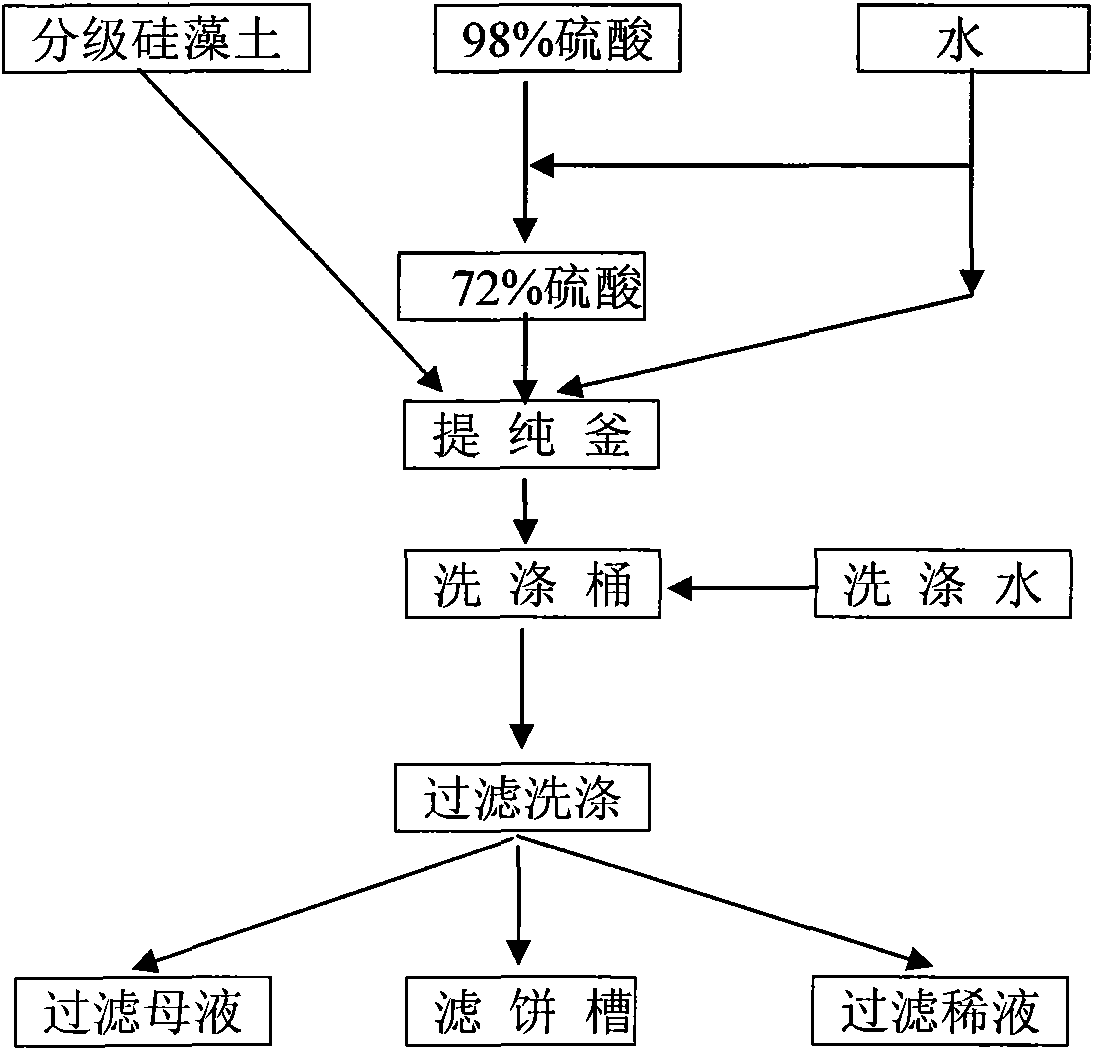

[0025] Purifying refined diatomite from raw ore comprises the following steps:

[0026] Dry the diatomite raw ore to a moisture content of 0-2%, sort and remove sand with an airflow turbine separator to remove gravel and impurities with a particle size > 43 μm, and then use a rotary kiln for calcination to remove organic matter. The calcination temperature is 500 ℃, heat preservation and calcination time 90min

[0027] Wet acid leaching: Put 1680kg of sulfuric acid with a concentration of 72%, and 420kg of the above-mentioned sorted diatomaceous earth into the reaction kettle, carry out wet chemical purification with sulfuric acid, further remove the acid-soluble impurities in the diatom shell, and dredge the diatoms. When the temperature of the reaction kettle reaches 100°C, keep warm for 4 hours; after keep warm for 4 hours, inject 1600L of clean water, and keep warm for 1 hour;

[0028] Filtration and washing: inject the purified solution in the above reaction kettle into ...

Embodiment 2

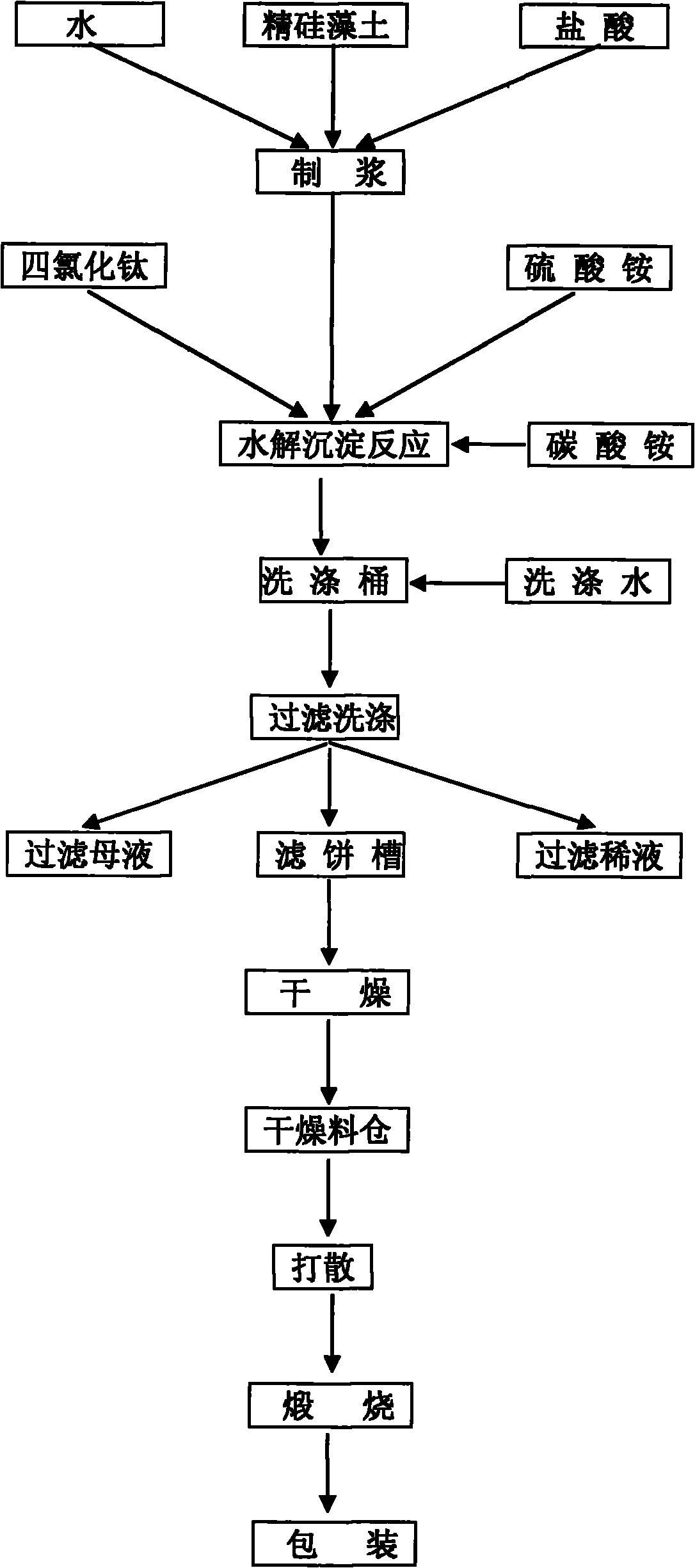

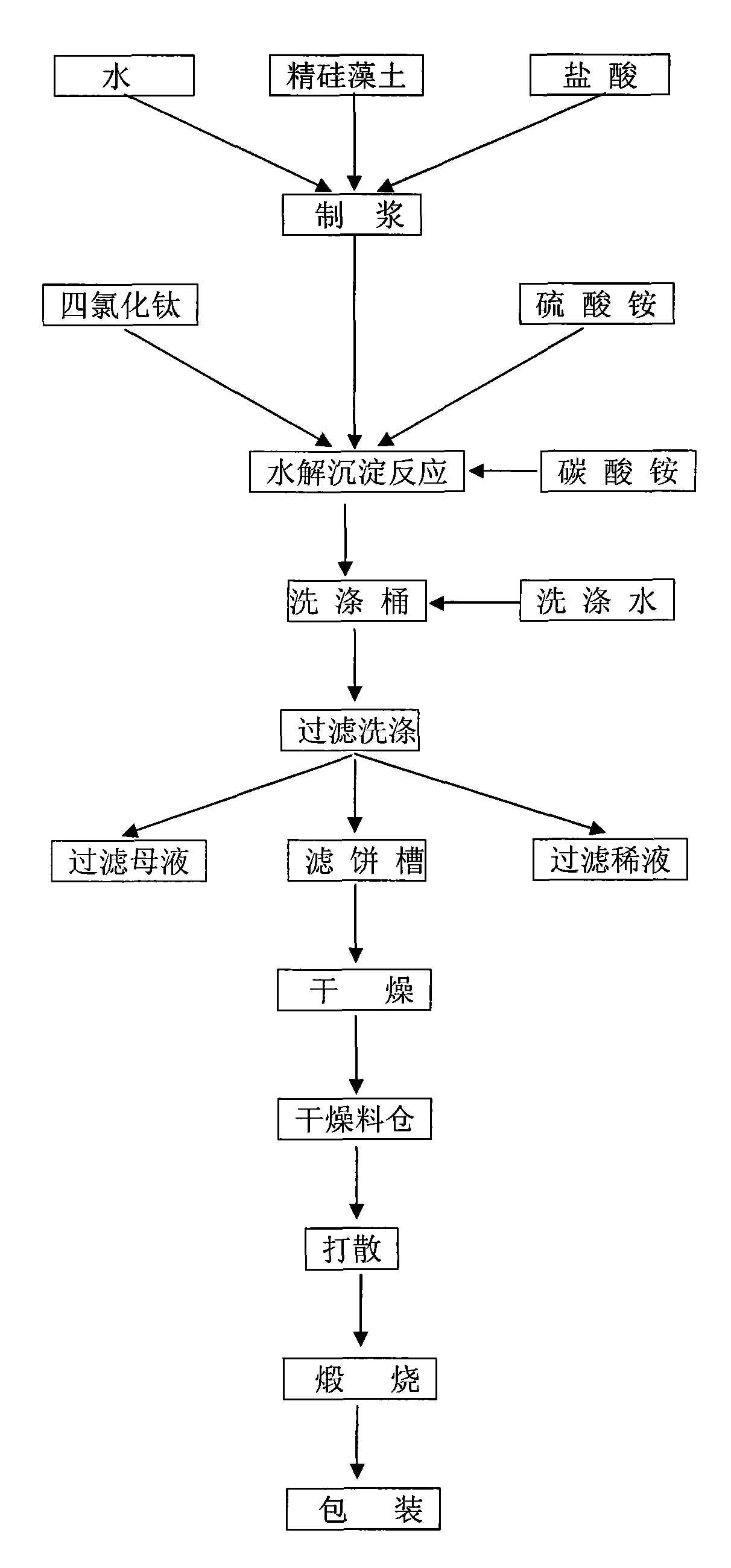

[0042] In the described pulping step, the concentration is 36% hydrochloric acid solution: water = 308.2: 30: 6000 in parts by weight;

[0043] In the described hydrolysis precipitation step, be the titanium tetrachloride of 200g / L by weight part concentration: concentration is the ammonium sulfate of 200g / L: the ratio of the ammonium carbonate=339:308.2:308.2 that concentration is 200g / L carries out hydrolysis precipitation reaction;

[0044] In the step of filtering and washing, filter and wash in the ratio of parts by weight refined diatomaceous earth: water = 308.2: 13000;

[0045] In the drying step, the drying temperature is 300°C, and the drying is stopped when the water content reaches 0-6%;

[0046] In the calcination step, the calcination time is 6 hours, and the calcination temperature is 620°C;

[0047] Other steps are the same as in Example 1.

Embodiment 3

[0049] In the pulping step, after mixing in the ratio of refined diatomite in parts by weight: hydrochloric acid solution with a concentration of 36%: water = 260: 12: 5000, stir for 7 minutes;

[0050] In the described hydrolysis precipitation step, be the titanium tetrachloride of 200g / L by weight part concentration: the ammonium sulfate that concentration is 200g / L: the ratio of the ammonium carbonate=280:240:240 that concentration is 200g / L carries out hydrolysis precipitation reaction;

[0051] In the described filtering and washing step, filtering and washing is carried out in a ratio of parts by weight refined diatomaceous earth: water = 260: 10000;

[0052] In the drying step, the drying temperature is 280°C;

[0053] In the calcination step, the calcination time is 3 hours, and the calcination temperature is 700°C;

[0054] Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com