Process and device for producing ultrathin vitrified tile

A production process and production equipment technology, which is applied in the production process and equipment field of ultra-thin vitrified ceramic tiles, can solve the problems of unsatisfactory brick blanks, uneven brick surfaces, high scrap rate and high cost, and improve the rate of finished products and production. Efficiency, avoiding cracked bricks and uneven effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

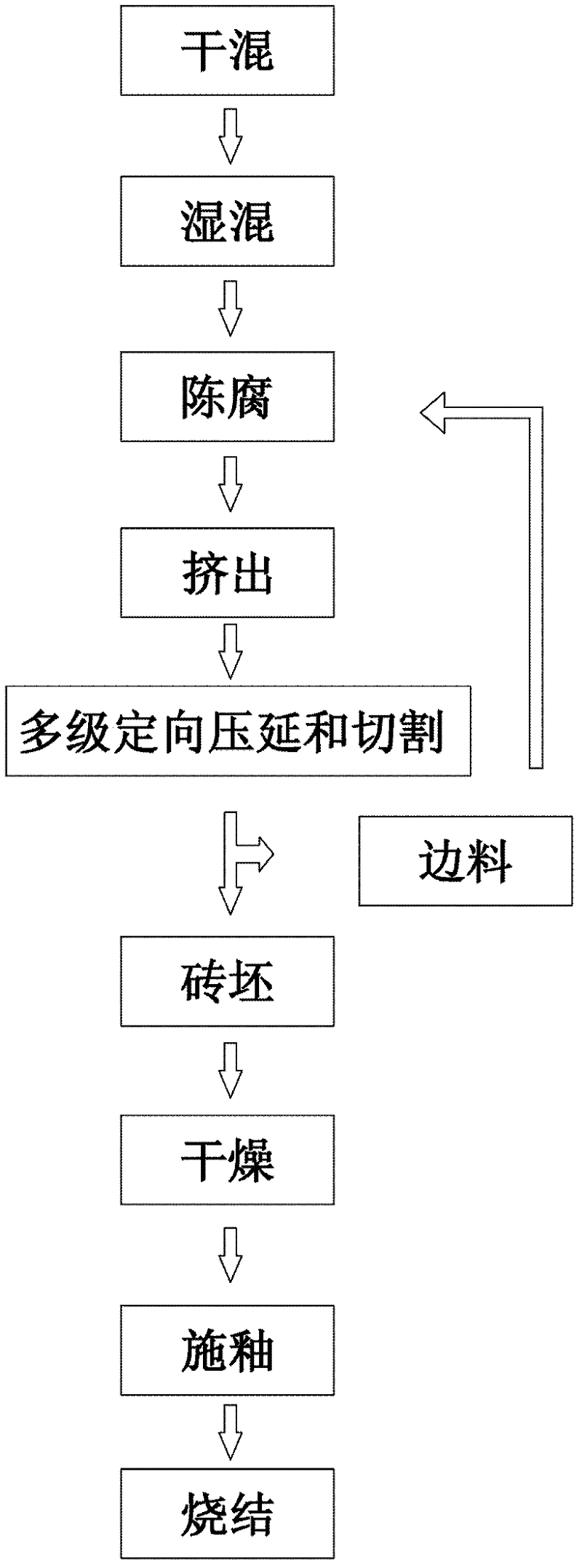

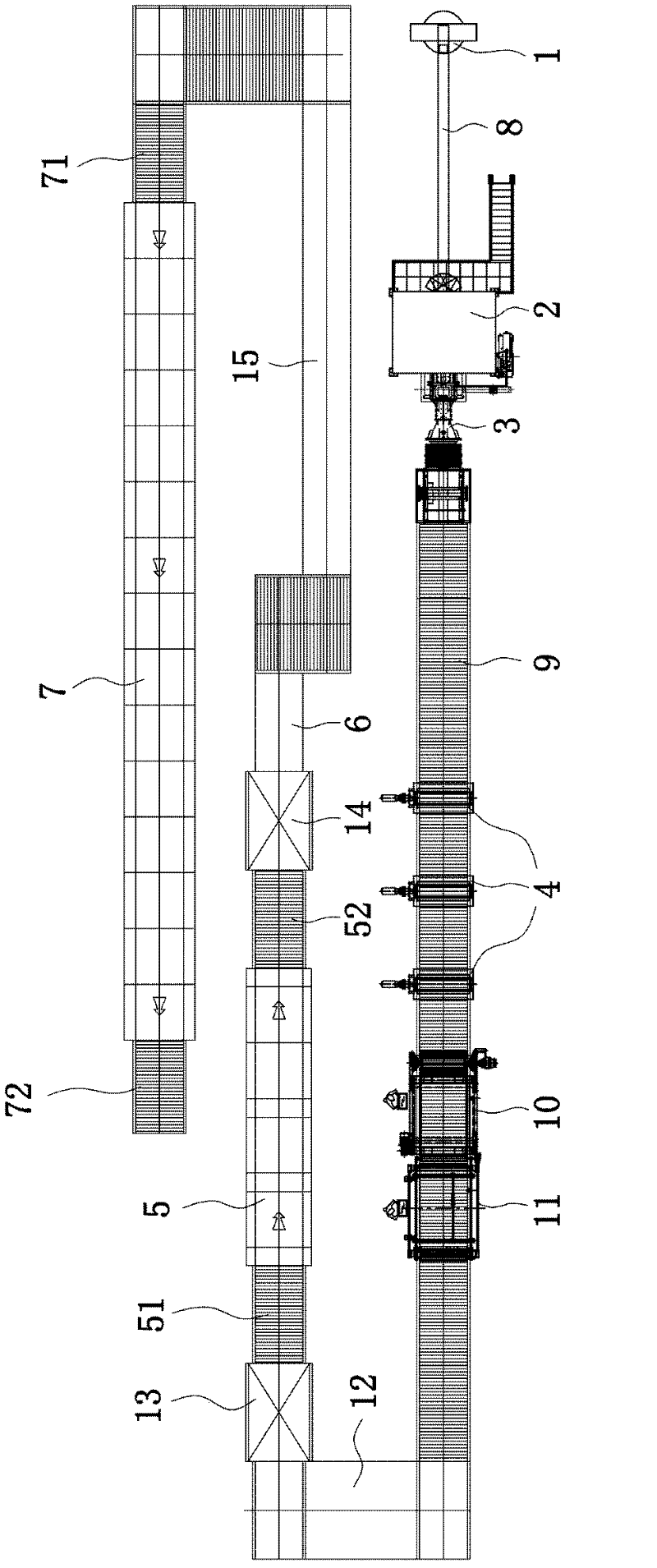

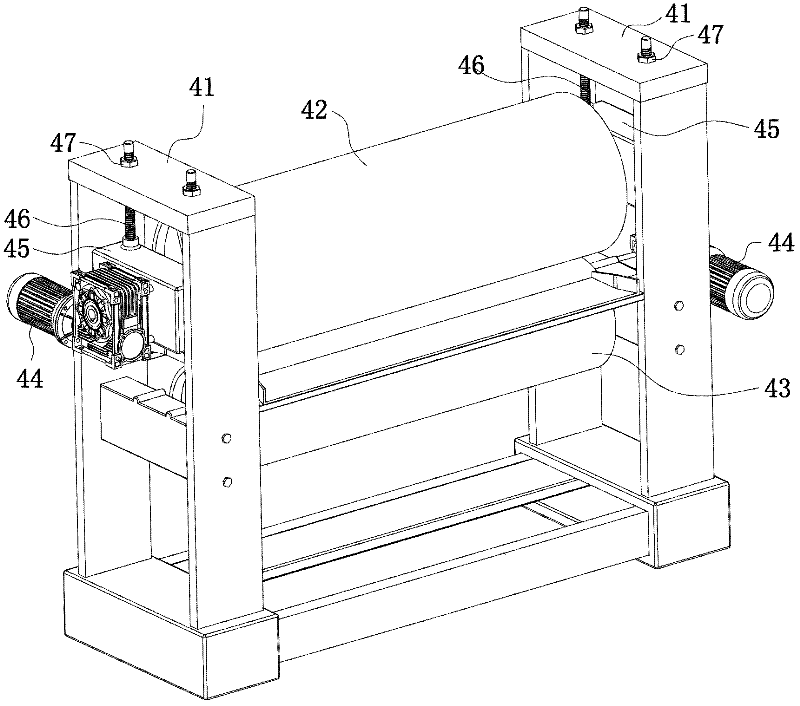

[0025] Attached below figure 1 The present invention will be further described by taking the production of ultra-large and ultra-thin vitrified ceramic tiles with a specification of 1500×3200×4-6 mm as an example. The preferred implementation of the present invention is as follows: first dry mix various powder materials required for the product in a mixer, and then add water through a quantitative water meter for wet mixing after mixing evenly. The moisture content of the mud after wet mixing remains Between 15%-18%. Then the mud enters the aging bin through the conveyor belt for aging, and the aging time is not less than 12 hours. The stale mud is fed into the extruder and mixed with coloring materials to extrude semi-finished bricks with a width of 1500mm and a thickness of 38mm with natural texture and color, and then make full use of the plasticity of the mud itself to go through the calender for three progressive The directional rolling finally makes the thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com