Novel one-component water-based adhesive and production technology thereof

A one-component, water-based adhesive technology, applied in the direction of adhesive types, ester copolymer adhesives, etc., can solve the problems of increasing the cost of building decoration, high cost of tile adhesive, unfavorable resource saving, etc., and achieves a reduction in materials. Cost, broad market prospects, and the effect of large promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

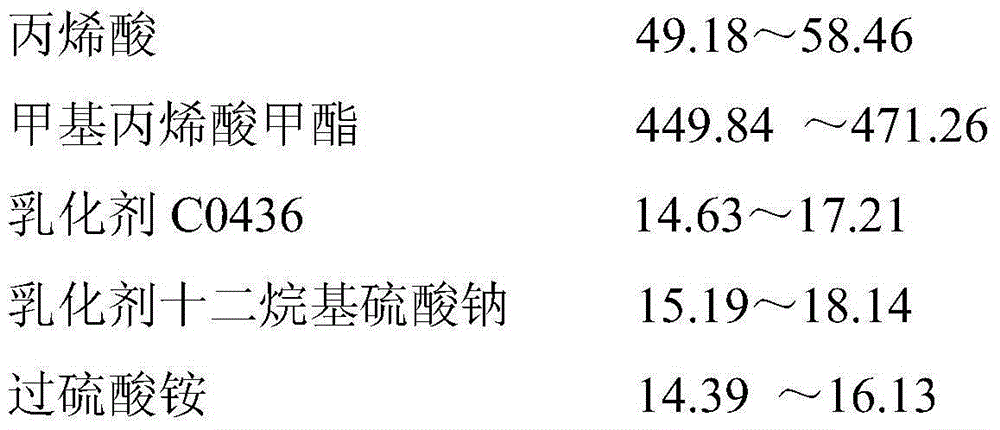

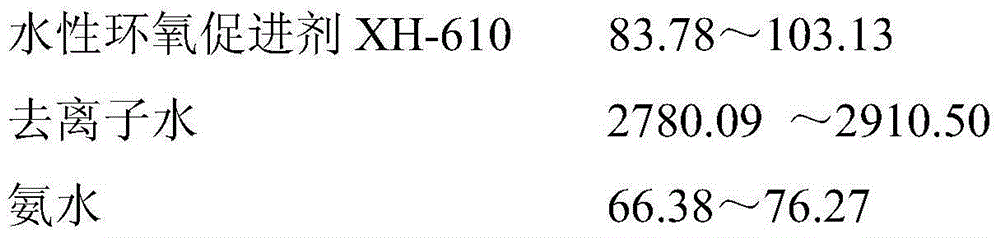

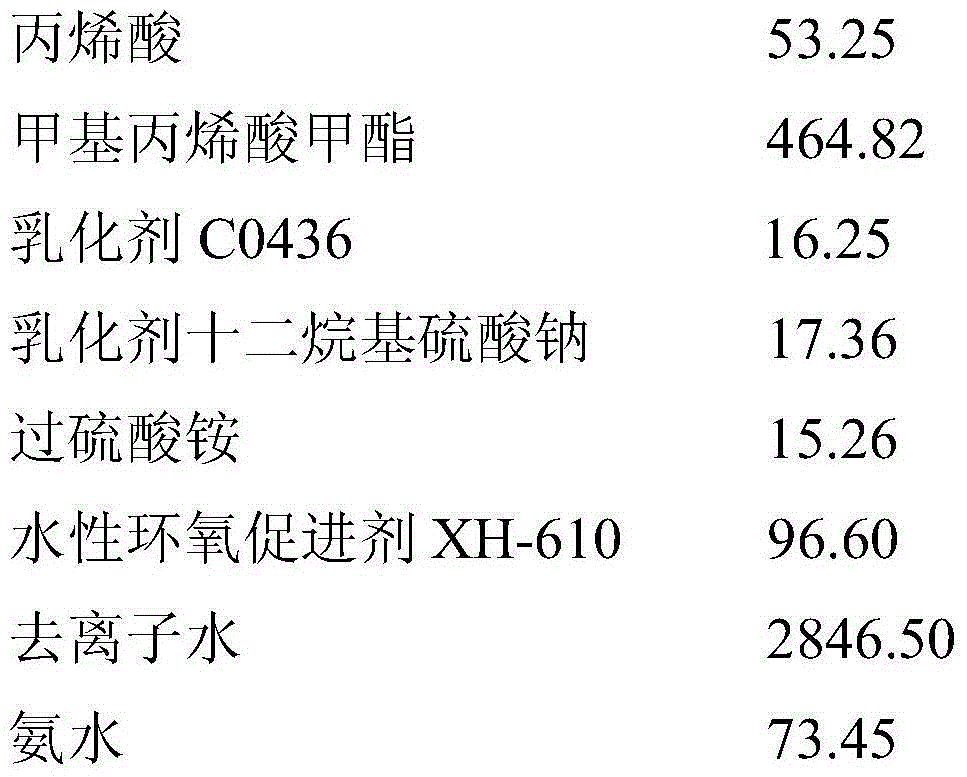

[0019] Provide a new type of one-component water-based adhesive, which includes the following components: acrylic acid, methyl methacrylate, emulsifier C0436, sodium lauryl sulfate, ammonium persulfate, water-based epoxy accelerator XH-610, Ionized water, ammonia water.

[0020] Among the components contained in the above-mentioned new type of one-component water-based adhesive: acrylic acid is the basic raw material of water-soluble polymers, and can improve the firmness of products; methyl methacrylate is the main monomer for producing transparent adhesives ; Emulsifier CO436 is a multi-purpose surfactant, which has the effect of accelerating monomer reaction and is not easy to delaminate; sodium lauryl sulfate is a non-toxic surfactant, and is also a commonly used emulsifier; persulfuric acid Ammonium is the initiator of acrylic emulsion polymers. The resulting emulsion has good water resistance and has a curing effect, and the curing speed is fast; the water-based epoxy ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com