Wet combining process for vitrified porcelain tiles

A vitrified tile and wet paste technology, which is applied in the processing, covering/lining, construction, etc. of building materials, can solve the problems of affecting the firmness of vitrified brick paving, affecting the construction quality, and falling off of vitrified bricks, so as to reduce the Empty drum and shedding phenomenon, improve the overall aesthetics, and ensure the smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

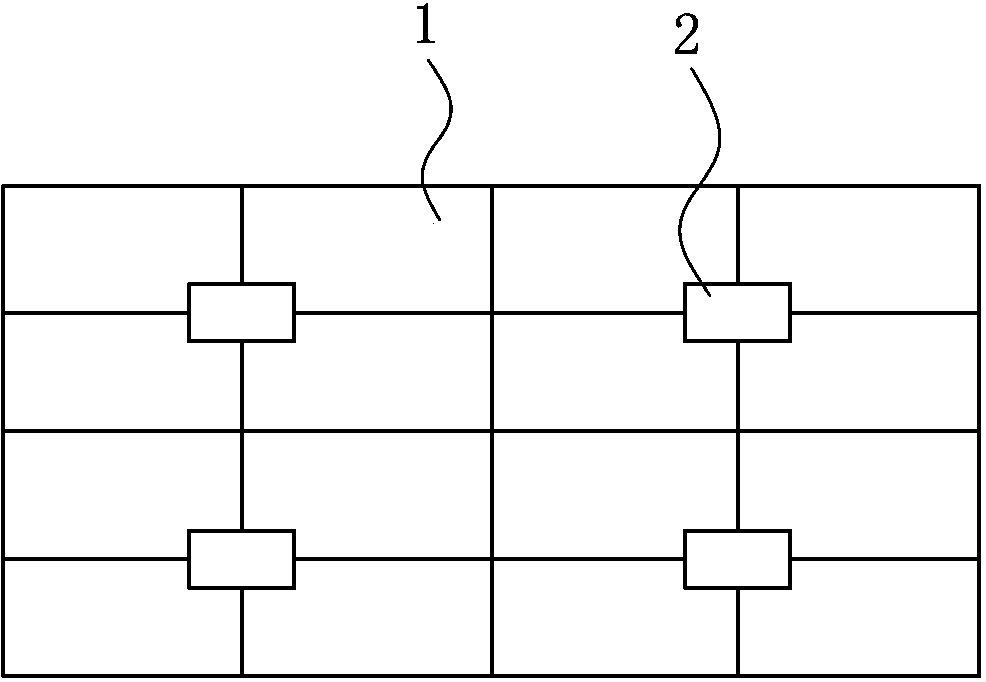

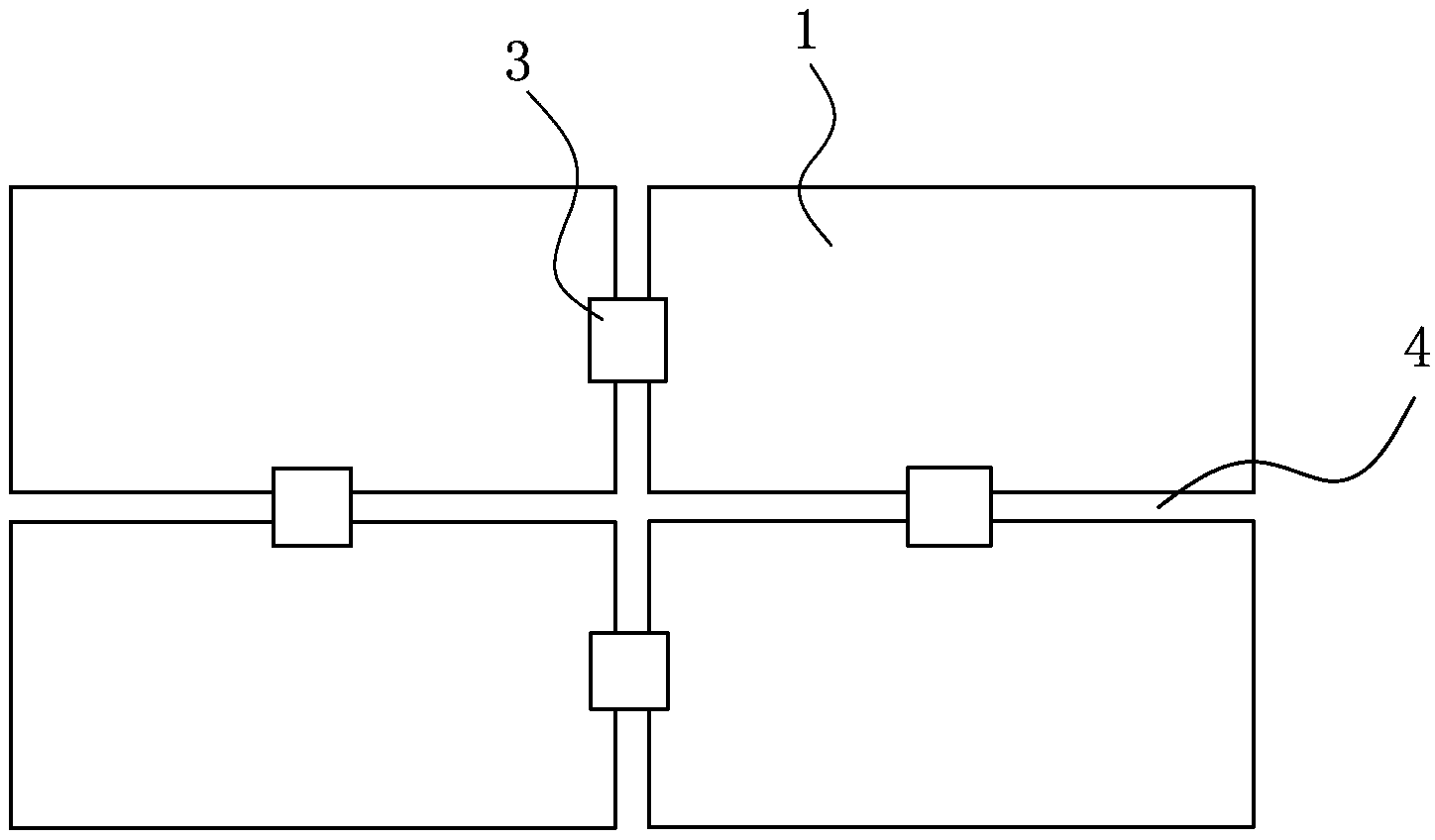

[0027] Embodiment one: see Figure 1~2 As shown, a wet paste process of vitrified tiles:

[0028] a. Vitrified brick 1 treatment: clean first, paste several reinforced small bricks 2 evenly on the back of each vitrified brick 1, and evenly paint the concrete interface agent on the back of vitrified brick 1 after drying;

[0029] b. Wall surface treatment: paint after eradicating the hollow wall, and evenly apply construction glue on the plaster layer;

[0030] c. Paving process: according to the construction facade grid drawing, paint the adhesive layer from bottom to top and then pave layer by layer; in the process of paving, a 0.8㎜~1.5㎜ wide space should be left between adjacent vitrified bricks 1. Gap 4; then paste temporary small pieces of vitrified bricks 3 at each gap 4, and connect vitrified bricks 1 on both sides; after paving and pasting is completed, sprinkle water for maintenance after 1 to 2 days;

[0031] d. Gap treatment: 3 to 4 days after the paving is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com