Environmental-friendly single-component vitrified brick gum and preparation method thereof

A single-component, vitrified tile technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of easy to appear hollow phenomenon, easy shelling and peeling, not economical and practical, etc. Environmental protection features, simplified construction steps, simple construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0020] Embodiments 1 to 5 provide an environmentally friendly single-component vitrified tile adhesive, and the weight percentage content of each component of the vitrified tile adhesive is shown in Table 1;

[0021] The method for preparing described back glue comprises the steps:

[0022] a. Put 60% to 80% of the emulsion into the stirring device;

[0023] b. Put 0.2%~0.7% dispersant, 0.1%~0.3% defoamer, 0.3%~0.6% preservative, 10%~20.5% waterproofing agent into the stirring device in turn, and stir evenly;

[0024] c. Put 7% to 13% of adhesive, 0.1% to 0.3% of defoamer and 1.5% to 5% modifier into the device, and stir evenly to get an environmentally friendly single-component vitrified tile adhesive .

[0025] Table 1

[0026]

Embodiment 6

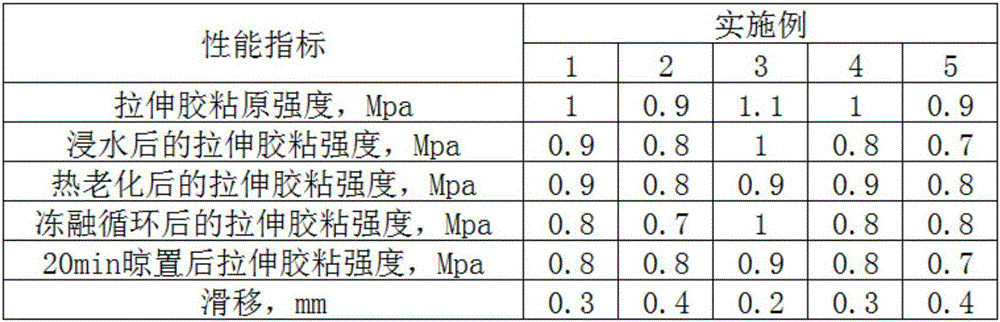

[0028] Carry out the performance test to the vitrified tile back glue that above-mentioned embodiment 1~5 makes, refer to JC / T547-2005 " ceramic wall and floor tile adhesive " judging standard to carry out performance test to vitrified tile back glue, its result is shown in Table 2 Show:

[0029]

[0030] It can be seen from Example 6 that an environmentally friendly single-component vitrified tile adhesive proposed by the present invention can fully meet the bonding requirements of vitrified bricks, so that vitrified bricks can be reposted on different substrates, effectively solving the problem of vitrified bricks. It solves the problems of hollowing, shelling and falling off when vitrified bricks are bonded, and the construction is simple, with the advantages of environmental protection and low cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com