Construction method and formwork structure for structure bottom plate and ground plate of underground pipe gallery

A technology of underground pipe gallery and construction method, which is applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve problems such as low construction efficiency, cracks on the floor, and narrow working space, so as to improve work efficiency, The effect of reducing construction costs and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

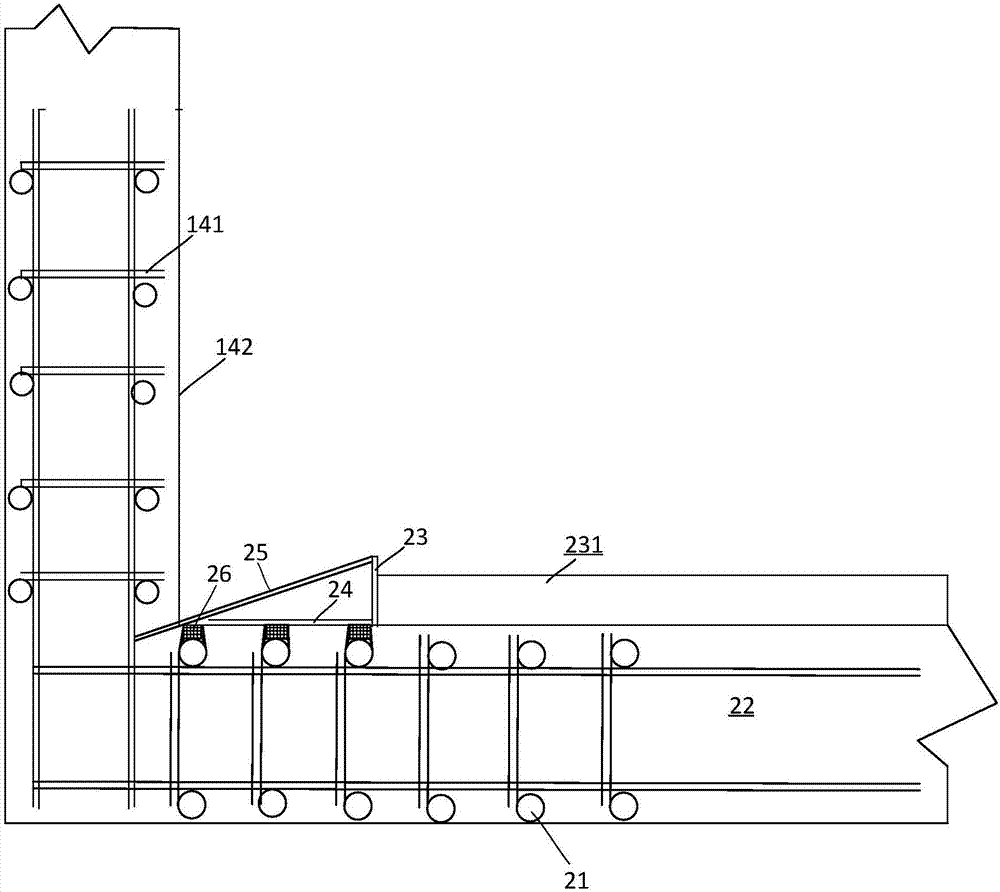

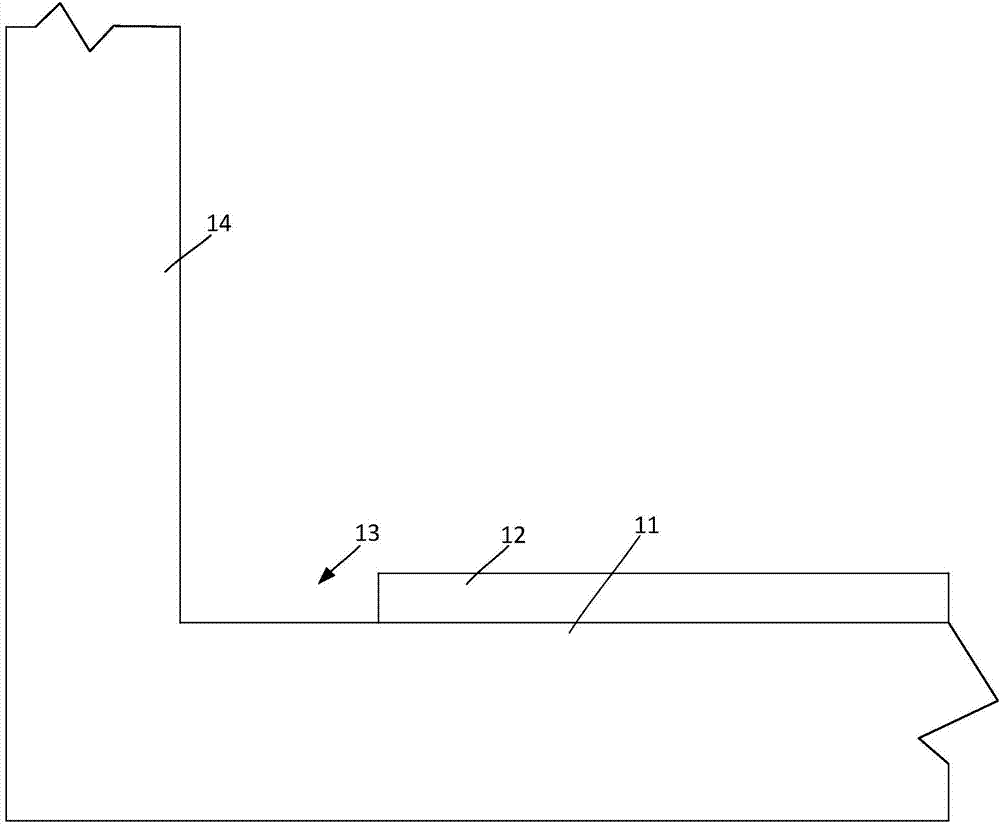

[0030] refer to figure 1 , the present invention provides a construction method for the structural bottom plate and floor plate of an underground pipe gallery and its formwork structure, which solves the problem that the construction of the floor plate in the prior art is carried out after the construction of the underground pipe gallery is completed, and there is a narrow light in the inner space of the pipe gallery Insufficient, the transportation of concrete materials is difficult, the construction efficiency is low, the floor slab and the structural bottom slab are constructed twice, and the floor slab is prone to cracks, hollowing and other quality defects. The invention adopts the construction method of one-time molding of the structural bottom plate and the floor plate of the underground pipe gallery, and constructs the floor plate at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com