Light steel keel and plasterboard vitrified tile decoration wall and method for constructing same

A light steel keel and construction method technology, applied to walls, building components, buildings, etc., can solve problems such as slow construction speed, falling off of decorative face bricks, difficult control of construction deviation, etc., achieve simple and convenient construction, reduce deformation, and facilitate firm adhesion degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

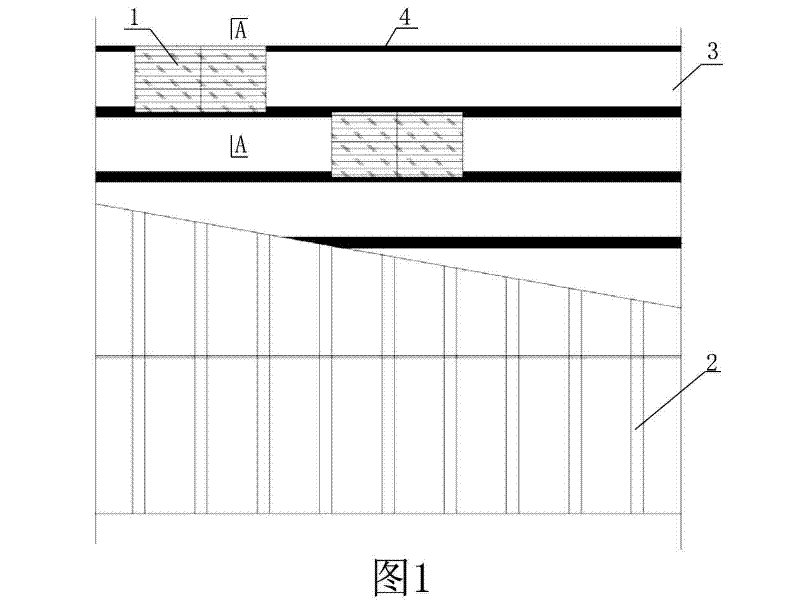

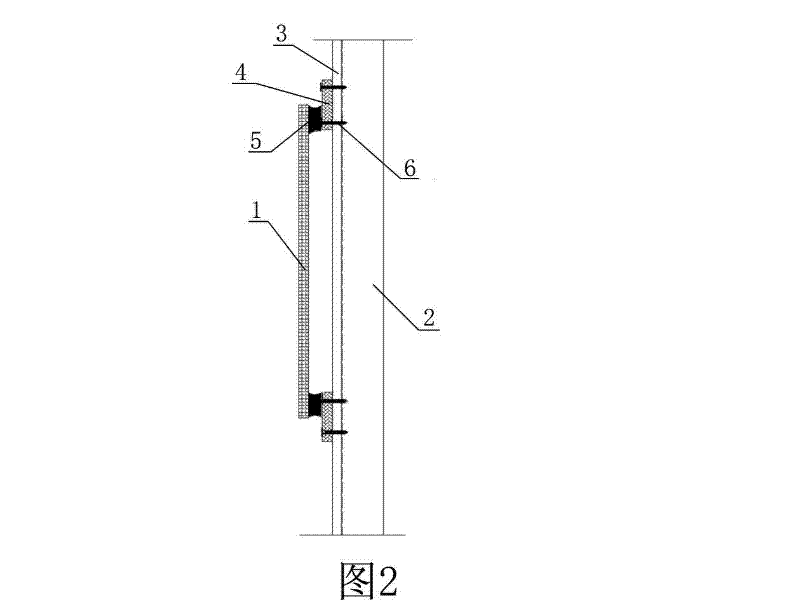

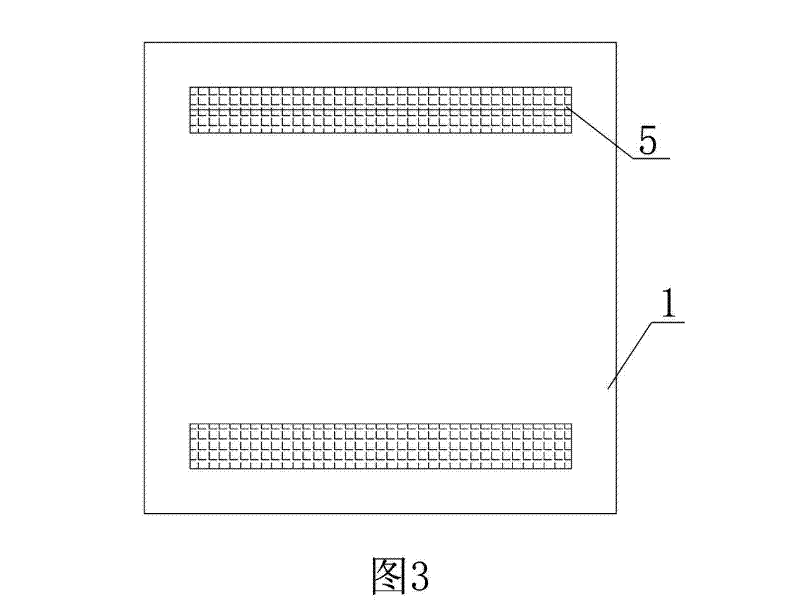

[0029] Examples see Figure 1 ~ Figure 3 As shown, a light steel keel gypsum board vitrified brick decorative wall includes a wall base and a decorative surface. The wall base is formed by attaching a gypsum board 3 to at least one side of a light steel keel 2. The outer surface of the gypsum board 3 On the surface, there are padding strips 4 arranged at intervals in the transverse direction, and the padding strips 4 are fixed together with the light steel keel 2 by self-tapping screws 6. 5 is pasted on two adjacent pad flat strips 4. The padding strip 4 is an FC strip, a calcium silicate strip or an Erter board. FC board (Fiber Cement board) is fiber cement board.

[0030] The backing plate strips are arranged in the center of the joints between the upper and lower vitrified bricks 1 . The thickness of the pad strip is 4-12 mm, and the width is 50-100 mm. There are at least two layers of AB glue, each with a thickness of 2 to 3 mm, and the distance between the outermost e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com