Building ceramic prepared from granite waste through wet process forming and preparation method of building ceramic

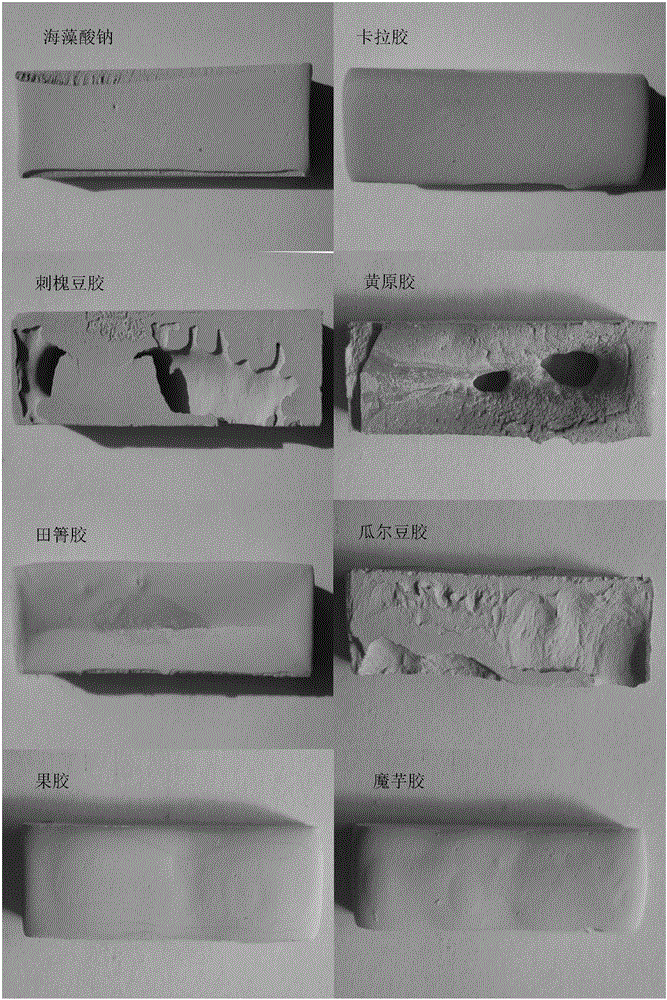

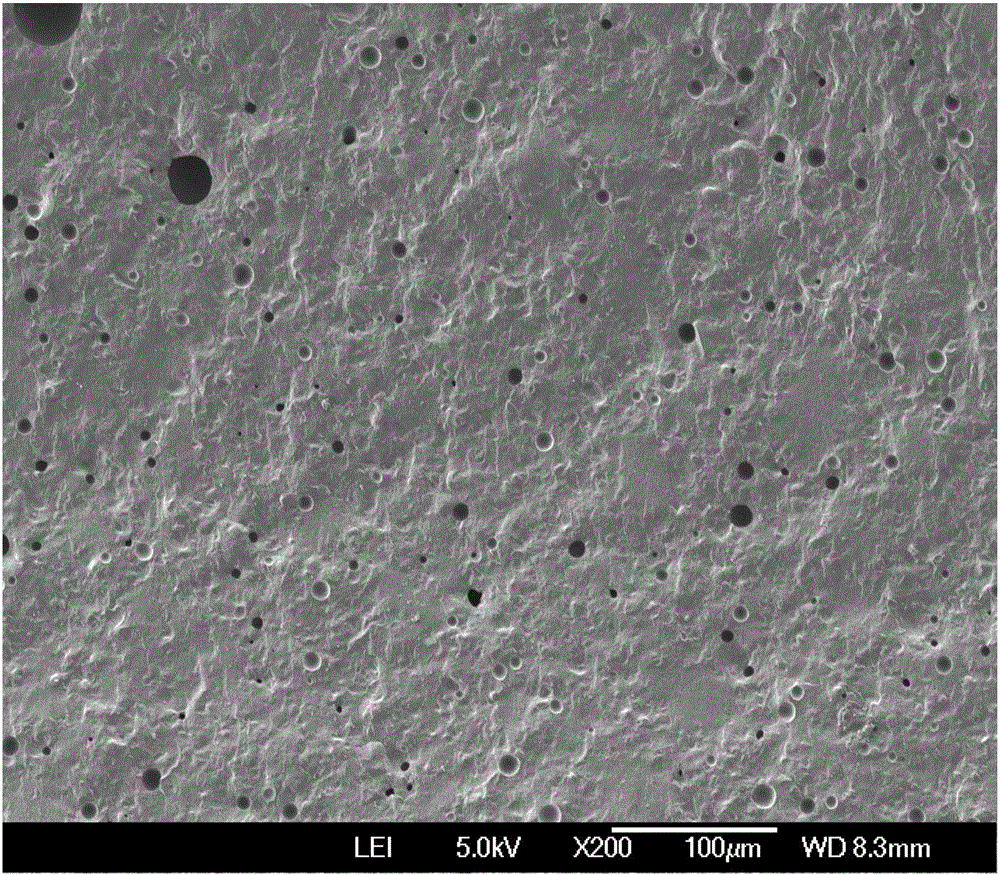

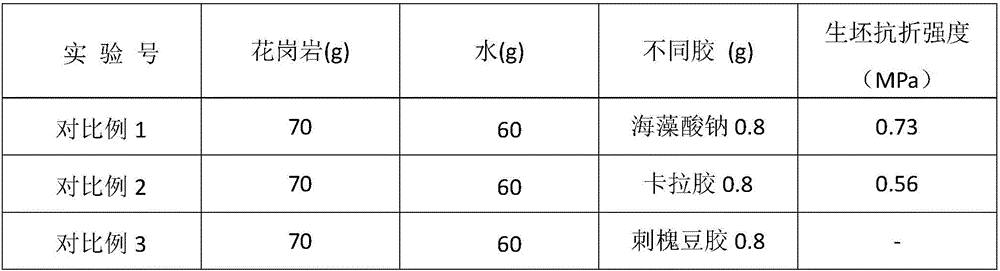

A granite waste, wet forming technology, applied in the field of building ceramics, can solve the problems of difficult flow, difficult to use large-scale decoction ceramic production, etc., and achieve the effects of low price, small porosity, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 The present invention utilizes the raw material of granite waste material wet forming (1)

[0051] Granite powder: 55 parts, water: 45 parts, locust bean gum and sodium alginate: 1 part, sodium humate and sodium hexametaphosphate: 1 part. The mass ratio of the locust bean gum to sodium alginate is 2:1. The mass ratio of the sodium humate to sodium hexametaphosphate is 1:1.

Embodiment 2

[0052] Embodiment 2 The present invention utilizes the raw material (2) of wet molding of granite waste

[0053] Granite powder: 50 parts, water: 50 parts, locust bean gum and sodium alginate: 0.5 parts, sodium humate and sodium hexametaphosphate: 2 parts. The mass ratio of the locust bean gum to sodium alginate is 2:1. The mass ratio of the sodium humate to sodium hexametaphosphate is 1:1.

Embodiment 3

[0054]Example 3 The present invention uses granite waste as raw material for wet molding (3)

[0055] Granite powder: 70 parts, water: 30 parts, locust bean gum and sodium alginate: 2 parts, sodium humate and sodium hexametaphosphate: 0.5 parts. The mass ratio of the locust bean gum to sodium alginate is 2:1. The mass ratio of the sodium humate to sodium hexametaphosphate is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com